Flying shear blade replacing method

A replacement method and technology of flying shears, applied in the field of flying shears blade replacement, can solve the problem of long time to replace flying shears blades, and achieve the effect of reducing manpower utilization, improving speed, reliability and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

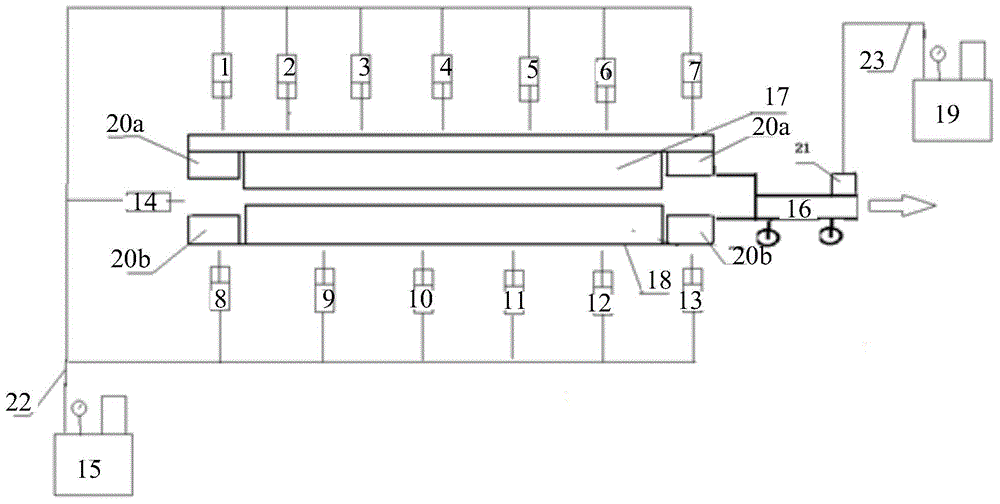

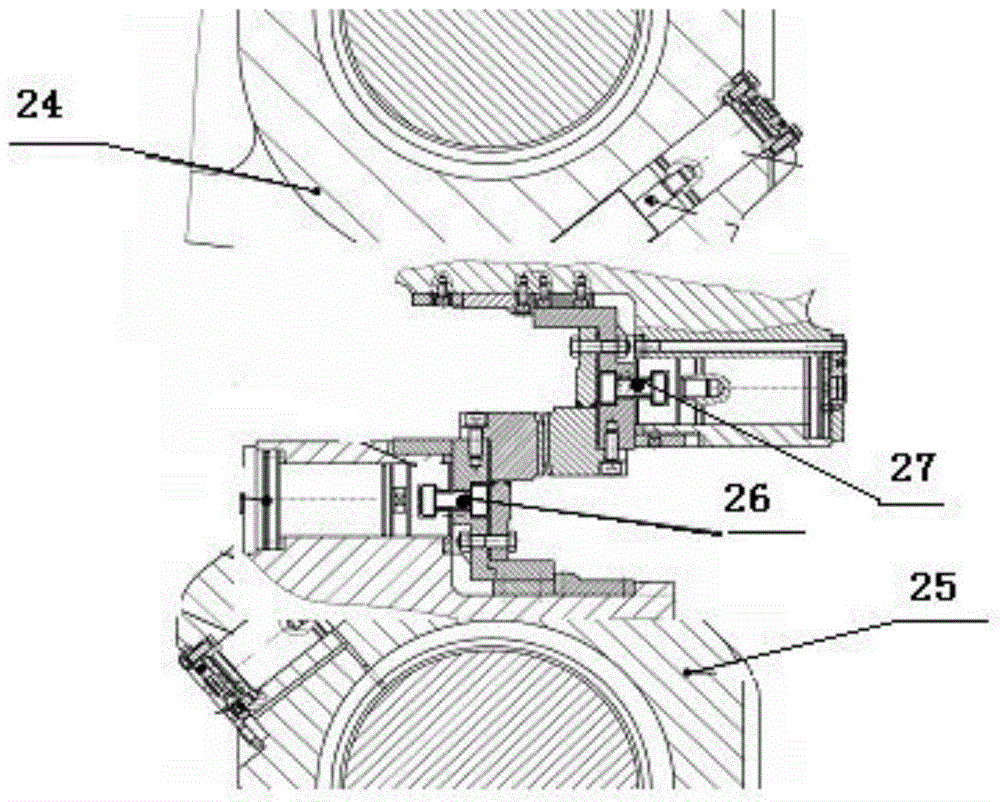

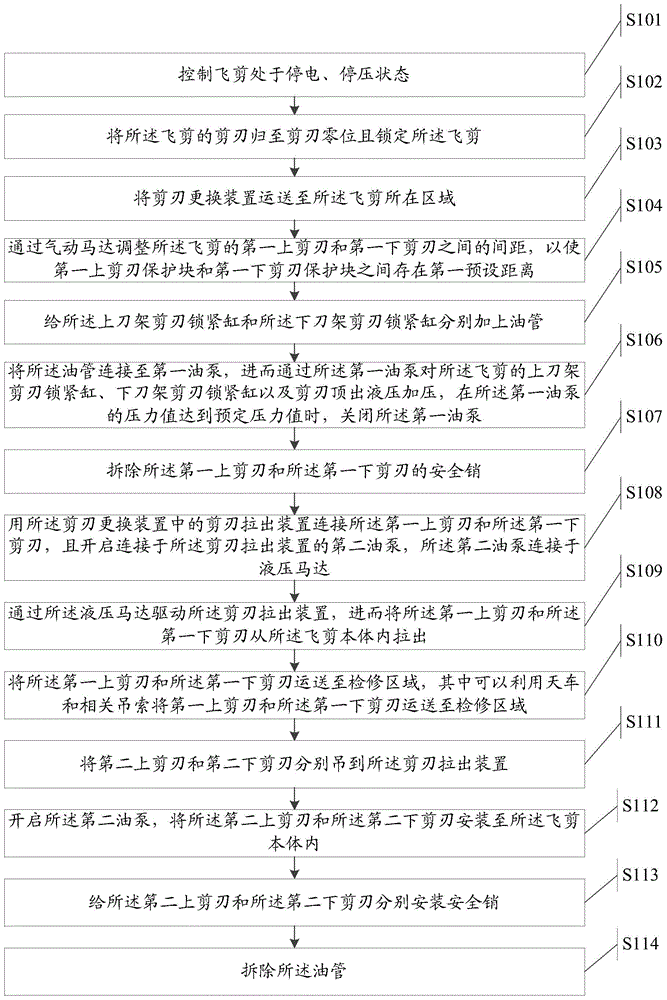

[0043] The invention provides a method for replacing the blades of flying shears to solve the technical problem in the prior art that it takes too long to replace the blades of flying shears.

[0044] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

[0045] When replacing the cutting blades of the flying shears, pressurize the upper blade holder locking cylinder, the lower blade holder blade locking cylinder and the shearing blade ejection hydraulic cylinder of the flying shears through the first oil pump, and the first oil pump is Compared with the existing manual manual pump, the movable oil pump has a higher reliability of the pressure gauge, reduces the manpower utilization rate, and saves the time-consuming separate pressing of the upper and lower tool rest locking cylinders of the flying shears;

[0046] Furthermore, the first upper cutting edge and the first lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com