Relief device for oil circuit of engine

a technology of oil circuit and relief device, which is applied in the direction of lubrication pressure control, machines/engines, pressure lubrication, etc., can solve the problems of large energy loss, difficult detail control of valves, and obstruct the improvement of fuel consumption at low temperature, so as to achieve accurate control and reduce oil pressure. , the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

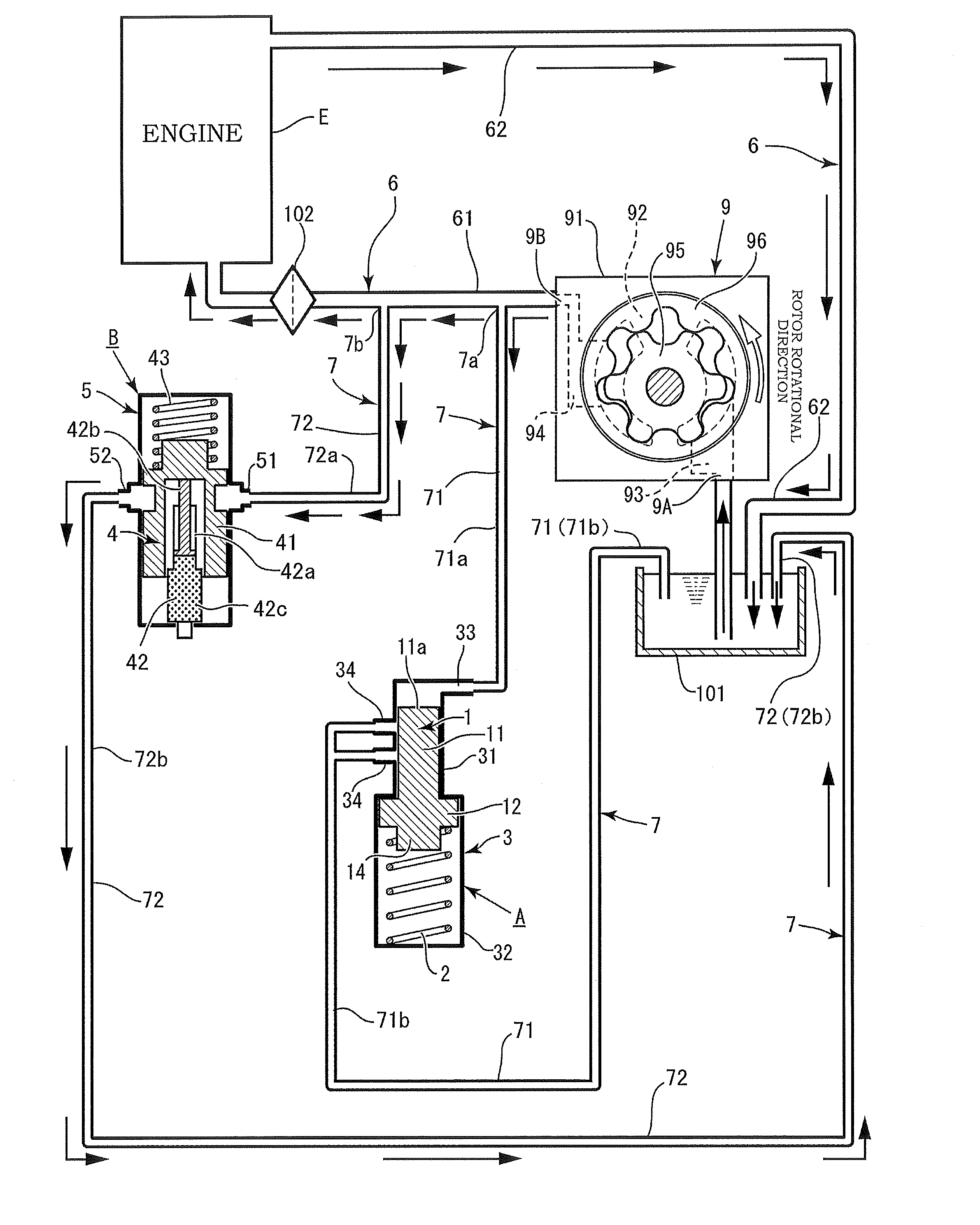

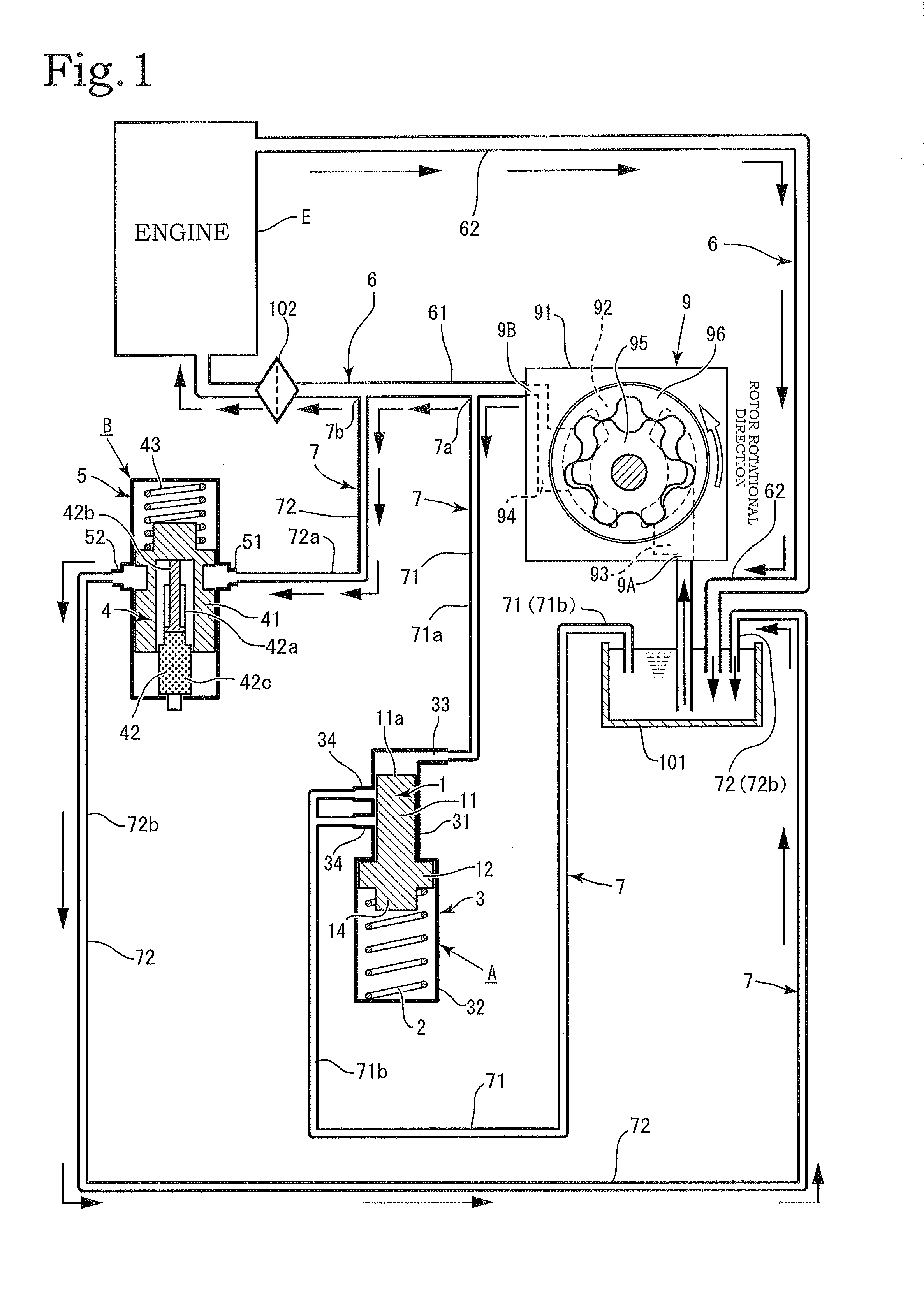

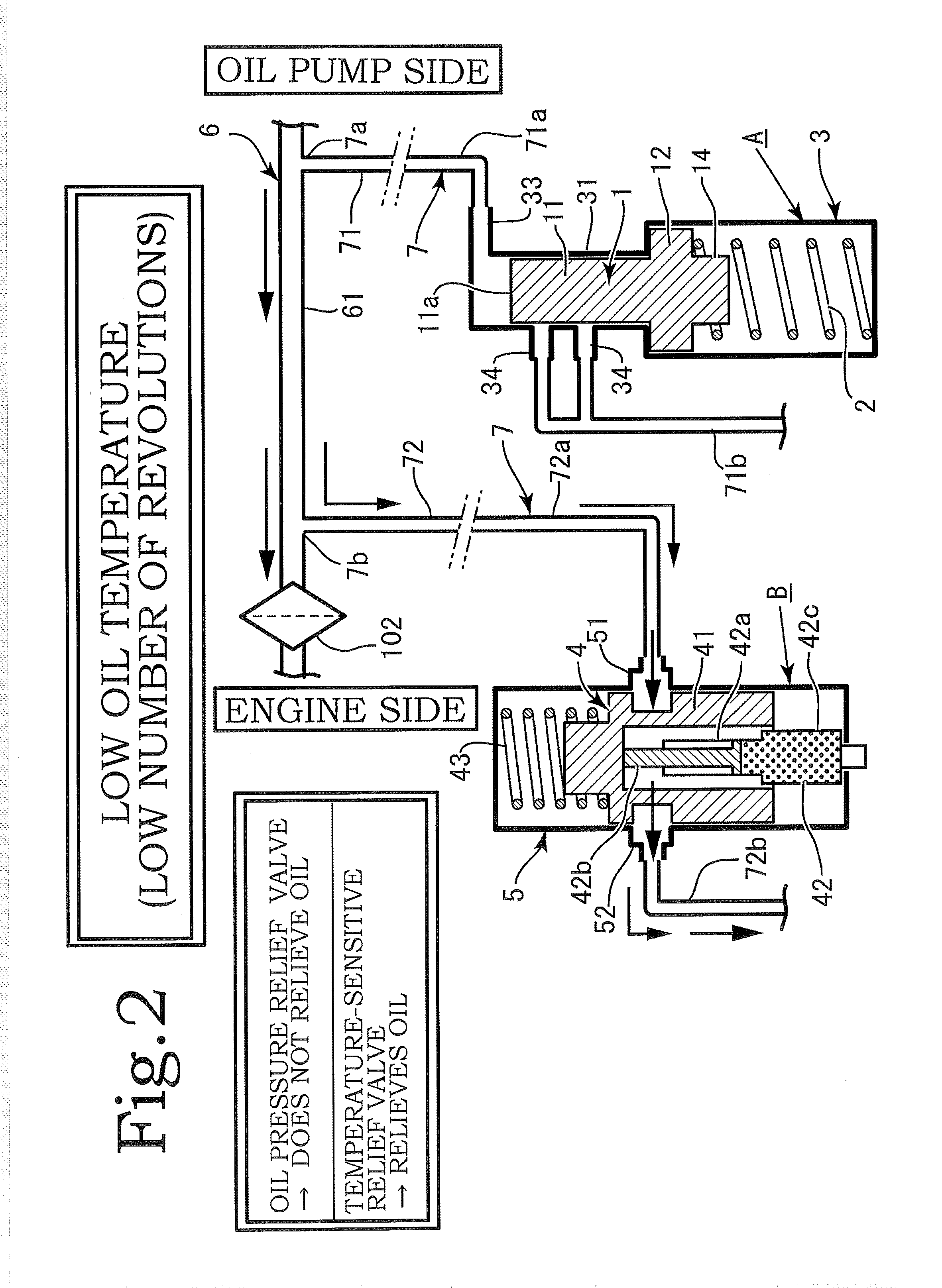

[0054]There are two embodiments for the configuration of the relief flow passage 7, and in the first embodiment, the relief flow passage 7 is divided into a first relief branch flow passage 71 which branches from the upstream flow passage 61 via a first branch section 7a at a position near the oil pump 9, and a second relief branch flow passage 72 which branches via a second branch section 7b at a position near the engine E (see FIG. 1).

[0055]Hence, the first relief branch flow passage 71 and the second relief branch flow passage 72 server as parallel flow passages, and the oil-pressure relief valve A is provided in the first relief branch flow passage 71 and the temperature-sensitive relief valve B is provided in the second relief branch flow passage 72, and by adopting a configuration of this kind, the oil-pressure relief valve A and the temperature-sensitive relief valve B are arranged in parallel.

[0056]The flow passage on the upstream side of the position where the oil-pressure ...

second embodiment

[0059]Moreover, in the relief flow passage 7, one upstream shared flow passage 73 which is connected to the intake section 9A of the oil pump 9 via an intermediate position in the upstream flow passage 61 of the oil circulation circuit 6 is provided, an upstream two-leg branch section′7c is provided at the end of the upstream shared flow passage 73, and the first relief branch flow passage 71 and the second relief branch flow passage 72 are provided in a parallel arrangement bifurcated from the upstream two-leg branch section 7c (see FIG. 8).

[0060]The oil-pressure relief valve A is provided on the side of one of the first relief branch flow passage 71 and the second relief branch flow passage 72, and the temperature-sensitive relief valve B is provided on the other thereof. A downstream two-leg branch merging section 7d is provided in the downstream end portion of the first relief branch flow passage 71 and the second relief branch flow passage 72, and a downstream shared flow passa...

third embodiment

[0086]In the third embodiment, when the oil temperature is medium, the amount of oil relieved by the temperature-sensitive relief valve becomes greater near a low temperature, and becomes smaller near a high temperature. A medium temperature is a temperature range between a low oil temperature and a high oil temperature. Accordingly, in the medium temperature range, there is a large temperature difference between the side near a low temperature and the side near a high temperature. Therefore, a large differential in the viscosity of the oil also occurs within the medium temperature range.

[0087]Consequently, when the oil temperature is medium, the viscosity of the oil is greater and the oil pressure increases, the lower the oil temperature, and the viscosity is smaller and the oil pressure decreases, the higher the oil temperature. Therefore, when the oil temperature is low within the medium temperature range, the temperature-sensitive relief valve implements control so as to increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com