Automatic-pressing production equipment for bittern bean curd and pressing method

A technology of automatic pressing and production equipment, applied in dairy products, cheese substitutes, applications, etc., can solve problems such as the inability to ensure that the pressing time and pressure of tofu are balanced, the quality of tofu cannot be guaranteed, and the lack of systematicness. Achieve the same pressing time, improve efficiency and uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

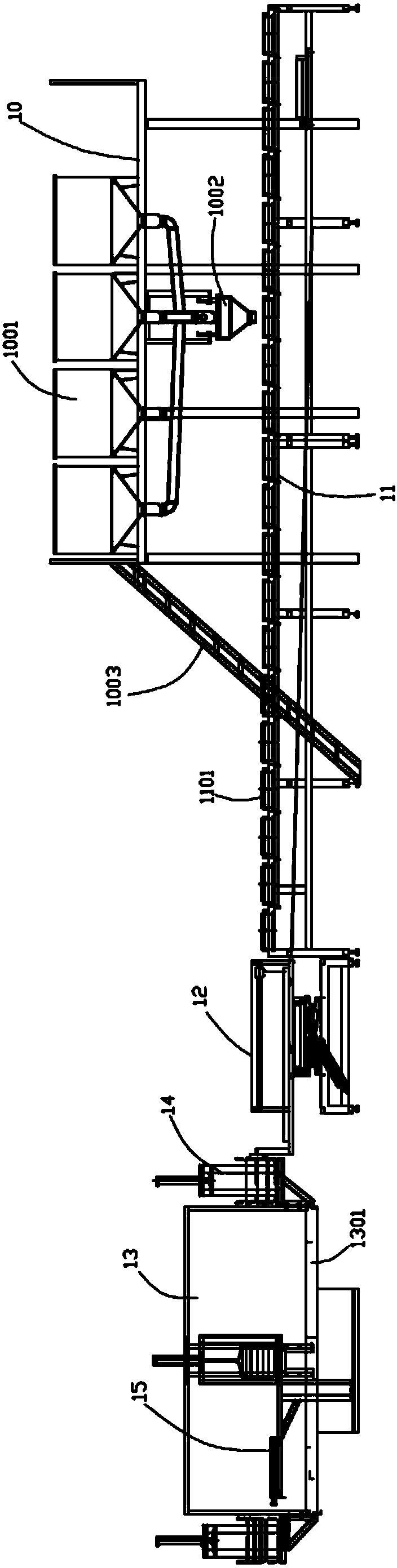

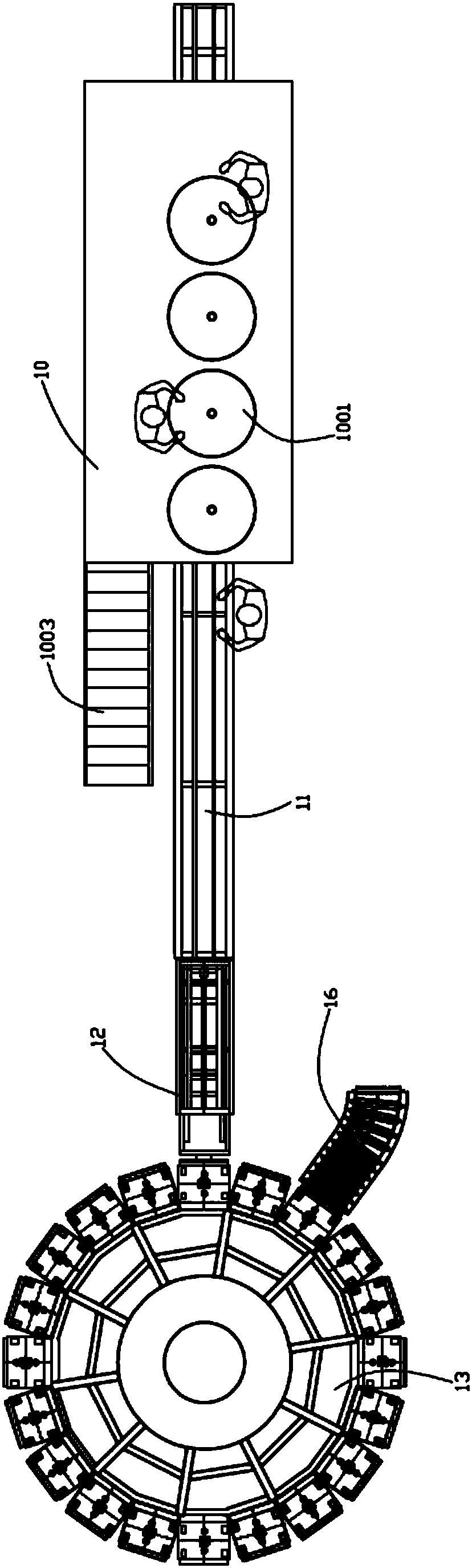

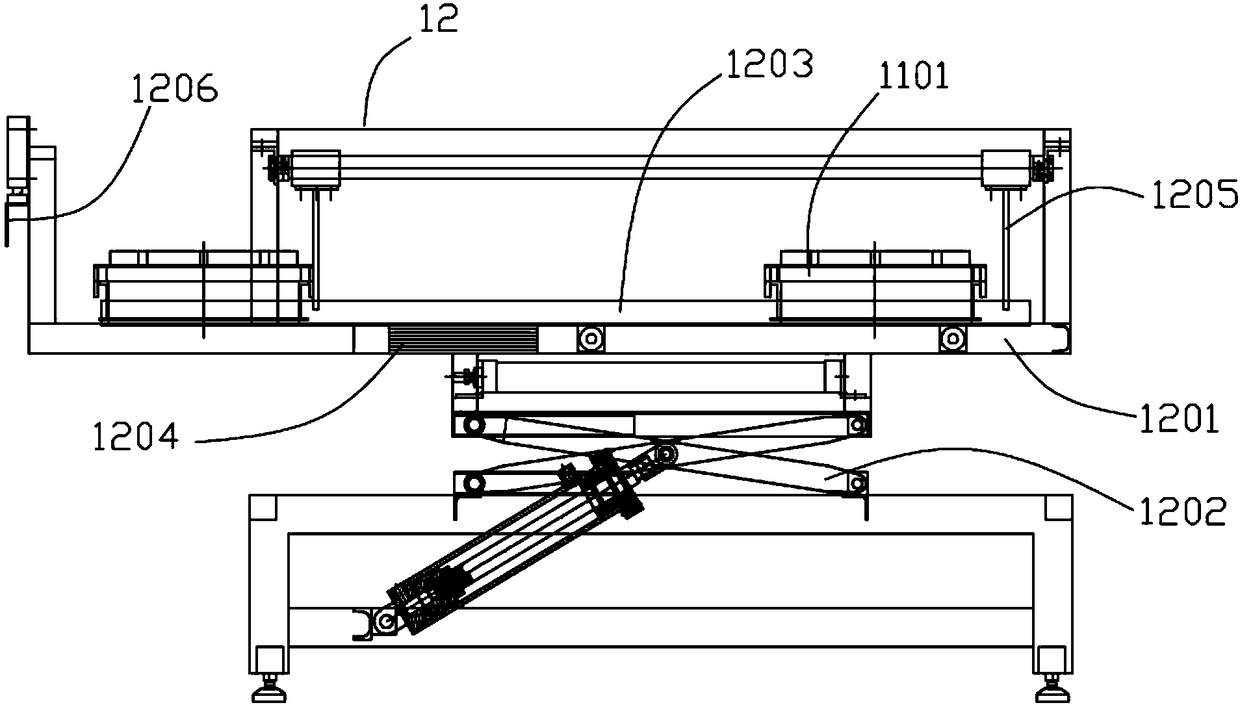

[0030] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —10: brine bean curd automatic pressing production equipment, comprising a slurry point bucket 1001 and a conveyor belt 11, the slurry point bucket 1001 is fixed on the top of the conveyor belt 11 by a support 10, a staircase 1003 is provided on the support 10, and the slurry point bucket 1001 is provided with four to Five, all have certain heat preservation effect, and all are equipped with stirring device in each pointing barrel 1001, quantitative barrel 1002 is arranged below pointing barrel 1001, each pointing barrel 1001 is connected on the quantitative barrel 1002 by pipeline, conveyer belt Bean curd frame 1101 is placed on 11, and the outlet of quantitative bucket 1002 is on the top of bean curd frame 1101, and the distance is relatively close, convenient discharging, when bean curd frame 1101 is placed on the conveyer belt 11, can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com