Vacuum laminating press suitable for various crisp material circuit boards

A vacuum lamination machine, brittle material technology, applied in the direction of lamination, lamination device, printed circuit, etc., can solve the problem that the positive pressure and the brittle material cannot be well fitted, the pressure is not the same, and the upper pressure plate cannot be automatically tilted slightly. and adjustment, to achieve the effect of simple product structure, balanced temperature and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing:

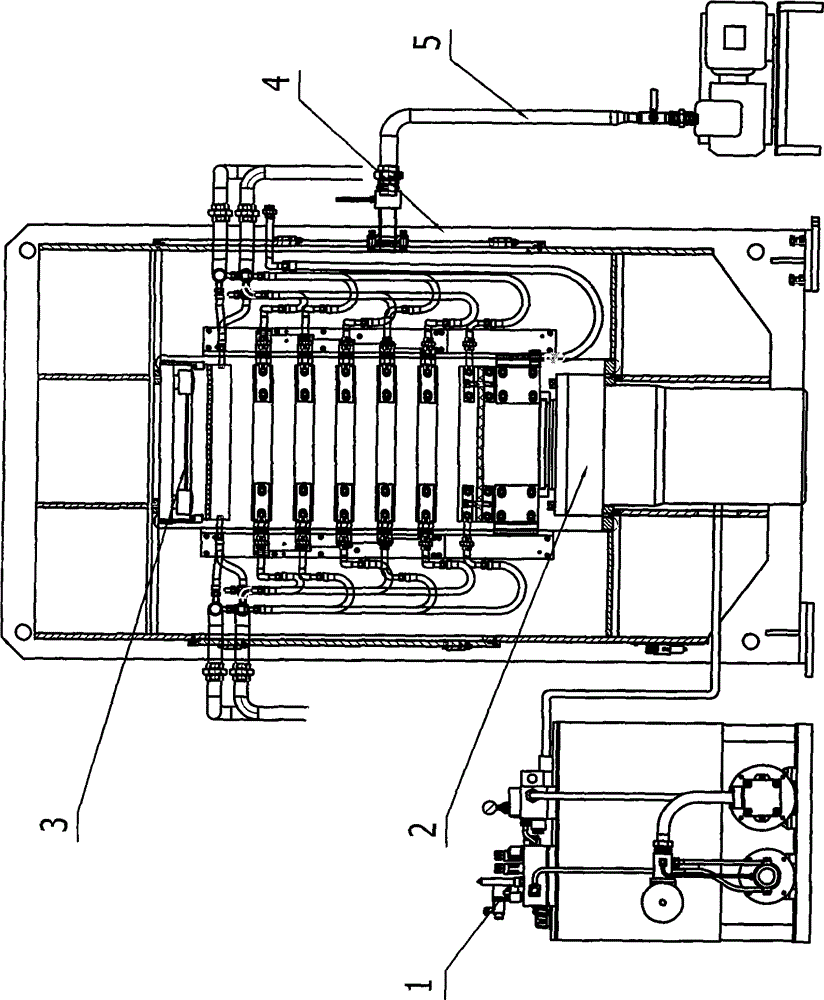

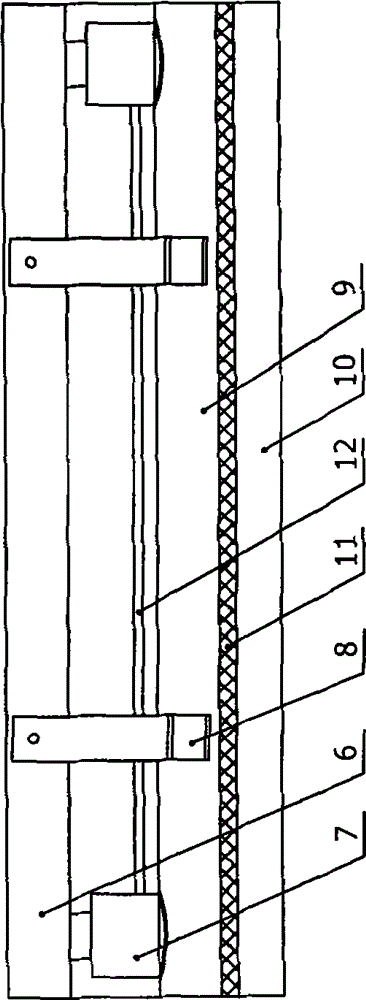

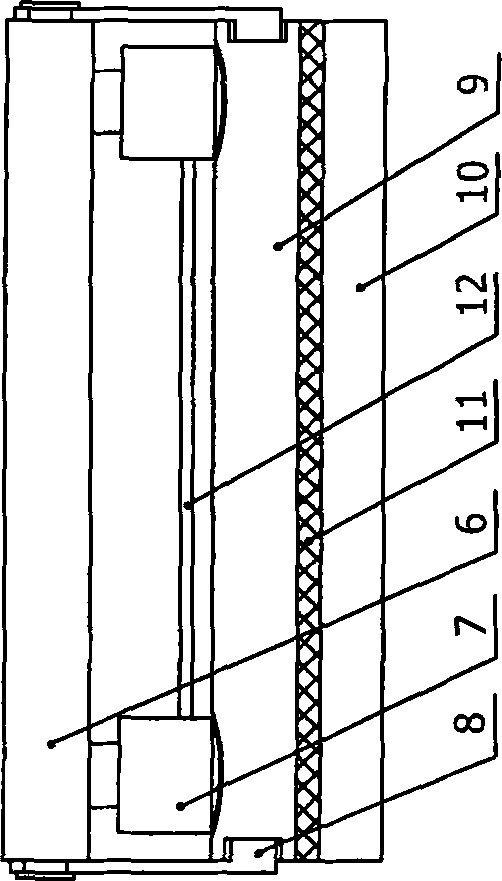

[0014] A vacuum pressing machine suitable for circuit boards of various brittle materials, which is mainly composed of a main frame body 4, a vacuum device 5, a hydraulic power device 1, and an electric control power system. The lower end of the main frame body 4 is provided with a pressure oil cylinder 2, the upper part of the pressure oil cylinder 2 is connected to the lower roof, and the top of the main frame body 4 is connected with a suspension balance mechanism 3. This suspension balance mechanism 3 has changed the non-movable plate 9 of the traditional press machine. Change the plane contact to multi-point contact, so that the movable plate 9 can tilt itself in a small amount in any direction within a certain range to achieve dynamic balance. Due to the multi-point support, the insufficient strength of the movable plate 9 and the upper pressing plate 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com