Front PTO transmission system, transmission case and tractor

A technology of transmission system and transmission box, which is applied in the field of transmission system and can solve the problems of small body, complex structure and increased machine mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

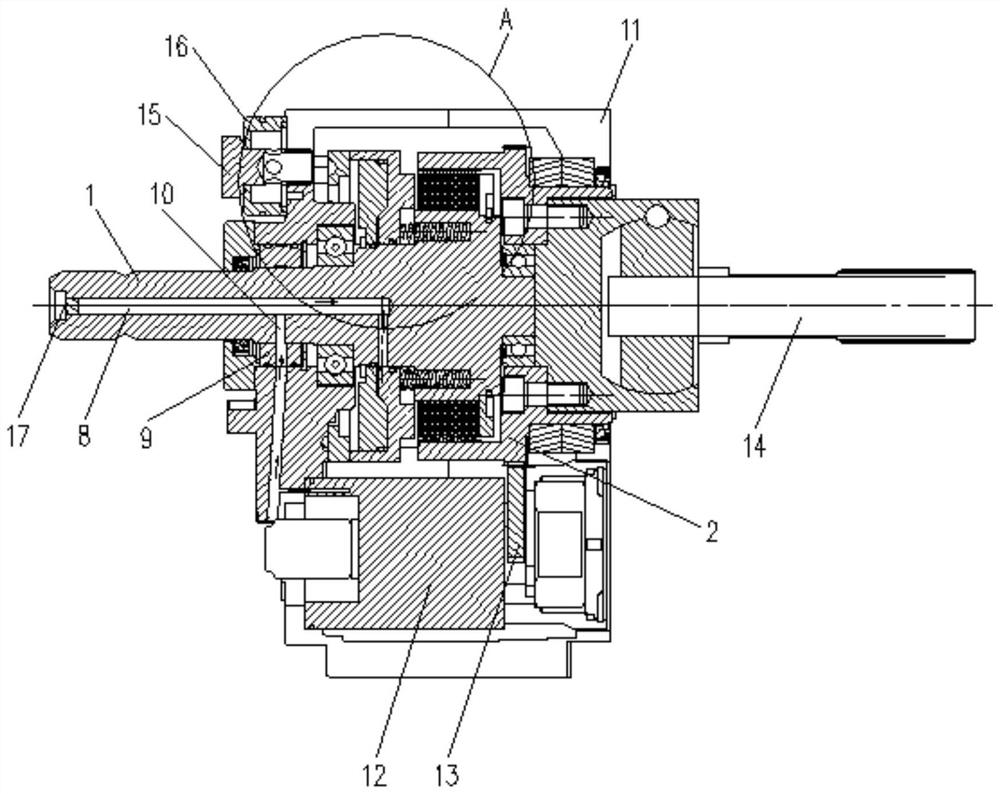

[0033] like figure 1 and figure 2 As shown, the present invention provides a front PTO transmission system, including a power output shaft 1 and an input gear 2, the power output shaft 1 can rotate around its own axis; the input gear 2 is coaxially rotated and sleeved on the power output shaft 1 It is combined with the power output shaft 1 through a hydraulic clutch and rotates with the power output shaft 1 or is separated from the power output shaft 1.

[0034] During transmission, the power is input by the input gear 2, and then the input gear 2 is combined with the power output shaft 1 through the hydraulic clutch and rotates with the power output shaft 1 to realize the rapid output of power; or separate from the power output shaft and stop the transmission, the structure is simple , the design is reasonable.

[0035] This embodiment can realize fast output of power, high transmission efficiency, compact structure, high integration, small occupied space and light weight....

Embodiment 2

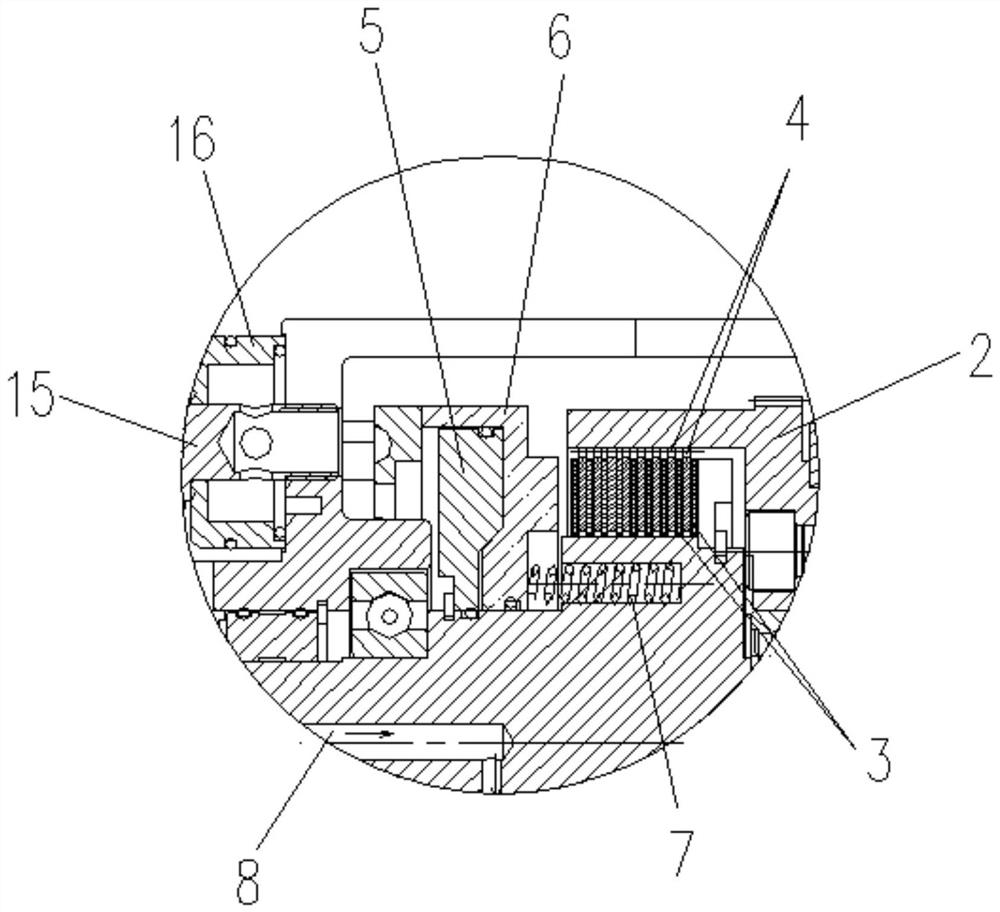

[0038] On the basis of Embodiment 1, in this embodiment, the hydraulic clutch includes a hydraulic drive mechanism and a friction plate assembly, one end of the input gear 2 extends to the other end of the power output shaft 1, and a mounting cavity is formed between the input gear 2 and the power output shaft 1 , that is, the input gear 2 has a cylindrical structure with one end closed and one end open, and a circular hole is arranged at the center of the closed end, and the circular hole is rotatably connected with the power output shaft 1 through a bearing; the friction plate assembly is installed on the power output shaft 1 Corresponding to the parts in the installation cavity, and are respectively connected with one end of the power output shaft 1 and one end of the input gear 2; the hydraulic drive mechanism is used to drive the friction plate assembly to combine or separate the power output shaft 1 and the input gear 2.

[0039] During transmission, the friction plate as...

Embodiment 3

[0042] On the basis of Embodiment 2, in this embodiment, the friction plate assembly includes a plurality of friction plates 3 and a plurality of steel plates 4 , and the plurality of friction plates 3 and the plurality of steel plates 4 are alternately coaxial along the axial direction of the power output shaft 1 . It is sleeved on one end of the power output shaft 1, and can slide along the axial direction of the power output shaft 1 respectively; the inner sides of the plurality of friction plates 3 are respectively provided with internal teeth meshing with the external teeth on one end of the power output shaft 1. The outer teeth of each steel plate 4 are respectively provided with external teeth meshing with the internal teeth on the inner side of one end of the input gear 2 .

[0043] During transmission, a plurality of friction plates 3 are respectively meshed with the power output shaft 1, and a plurality of steel plates 4 are respectively meshed with the input gear 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com