Gravity switching unit and aircraft engine inverted flight oil supply and ventilation device comprising same

An aero-engine and switching unit technology, applied in the directions of engine components, engine lubrication, turbine/propulsion lubrication, etc., can solve the problems of inconvenient disassembly, poor maintenance, large volume and weight of hydraulic accumulators, etc. The effect of maintenance, low weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

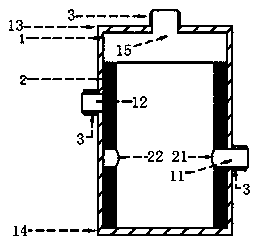

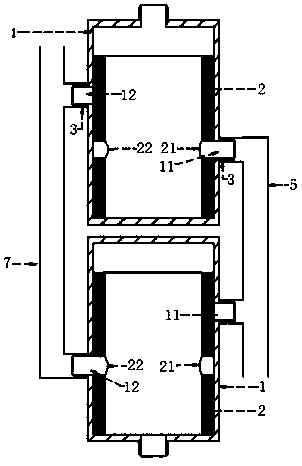

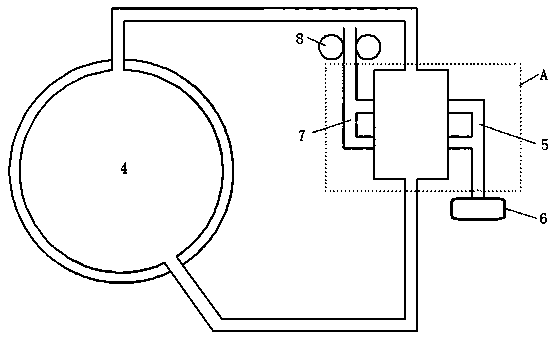

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] see figure 1 , the gravity switching unit of a specific embodiment, the casing 1, the casing 1 is a vertical hollow straight cylinder, the gravity switching cylinder 2 can be vertically slid inside the casing 1, the gravity switching cylinder The body 2 is also a vertical hollow straight cylinder; the outer wall of the gravity switching cylinder 2 corresponds to the inner wall of the housing 1, and the height of the gravity switching cylinder 2 is smaller than the height of the housing 1; A through hole I11 and a second through hole I12, a first through hole II21 and a second through hole II22 are respectively opened on the wall of the gravity switching cylinder 2, the first through hole I11 and the first through hole II21 are located in the same vertical On the plane and the distance from the first through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com