Rotating compressor of low pressure structure in shell

A rotary compressor, low-pressure technology, applied in the direction of rotary piston/oscillating piston pump components, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve high pressure resistance requirements, leakage , sealing and other issues, to avoid installation and sealing problems, low application difficulty, and good workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

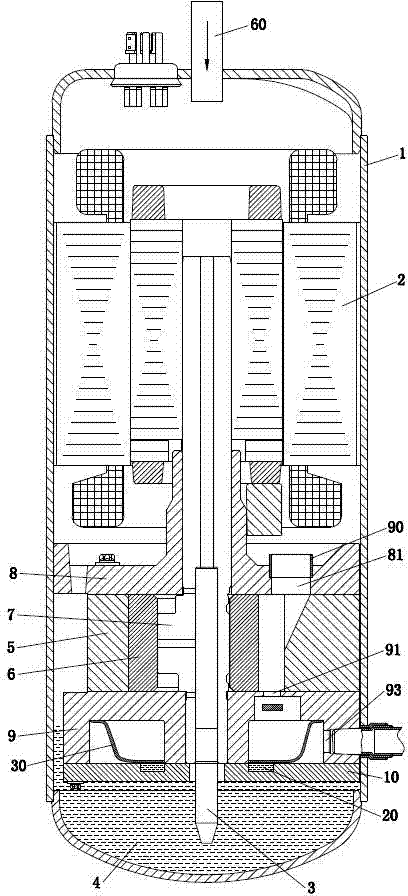

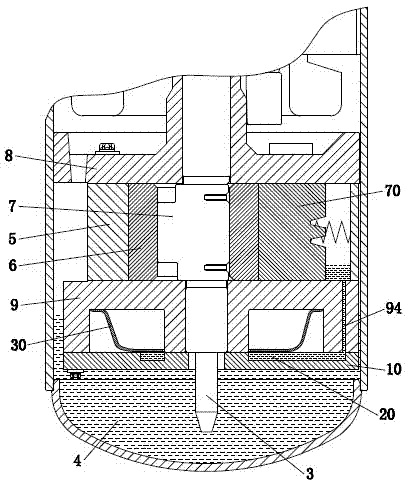

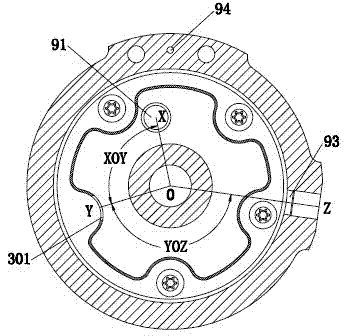

[0027] like figure 1 and figure 2 As shown, a rotary compressor with a low-pressure structure in the shell includes a closed shell 1, an air suction pipe 60 arranged on the top of the shell 1, a motor 2 set in the shell 1, a compression part, and an oil pump 3 ; The inner bottom of the housing 1 is provided with a first oil pool 4, and the compression part includes a cylinder 5 with a compression chamber, a piston 6 and a sliding plate 70 accommodated in the cylinder 5, and an eccentric crankshaft 7 that drives the piston 6 to rotate eccentrically. The upper end surface and the lower end surface of the cylinder 5 also support the upper bearing 8 and the lower bearing 9 of the eccentric crankshaft 7, wherein the upper bearing 8 is provided with an air inlet 81 communicating with the compression chamber, and an internal suction air inlet 81 is installed in the air inlet 81. Pipe 90, the height of the inner suction pipe 90 protruding from the end surface of the air inlet 81 is ...

Embodiment 2

[0040] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is that Figure 5 As shown, the muffler 30 is provided with a dividing plate 40, and a gap is provided between the edge of the dividing plate 40 and the muffler 30. The dividing plate 40 divides the muffler 30 into an upper space whose volume is M and whose volume is N. The lower space, the volume relation between the upper space and the lower space is: M=4N.

[0041] In this way, the gas discharged from the gas outlet 91 has a certain oil separation effect when flowing in the upper space, and the separated oil flows to the lower space through the gap, avoiding the secondary contact between the separated oil and the gas, and further improving the oil separation. Effect.

Embodiment 3

[0043] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that Image 6 As shown, a baffle 50 is provided between the second oil pool 20 and the exhaust hole 93 .

[0044] The baffle plate 50 can be installed independently, and can also be designed as an integral body with the muffler 30 . The baffle plate 50 prevents the gas from contacting the oil again before entering the exhaust hole 93, thereby improving the oil separation effect. In this way, the gas discharged from the compressor contains less oil, which improves the energy efficiency level of the refrigeration system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com