Synchronous control method for six-surface jacking press hydraulic oil cylinder

A six-sided top press and hydraulic cylinder technology, applied in the field of hydraulic control, can solve the problems of fluctuations in compression deformation resistance, large changes in repeat accuracy, and no uniform standard for the adjustment process of fixed throttle valves, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

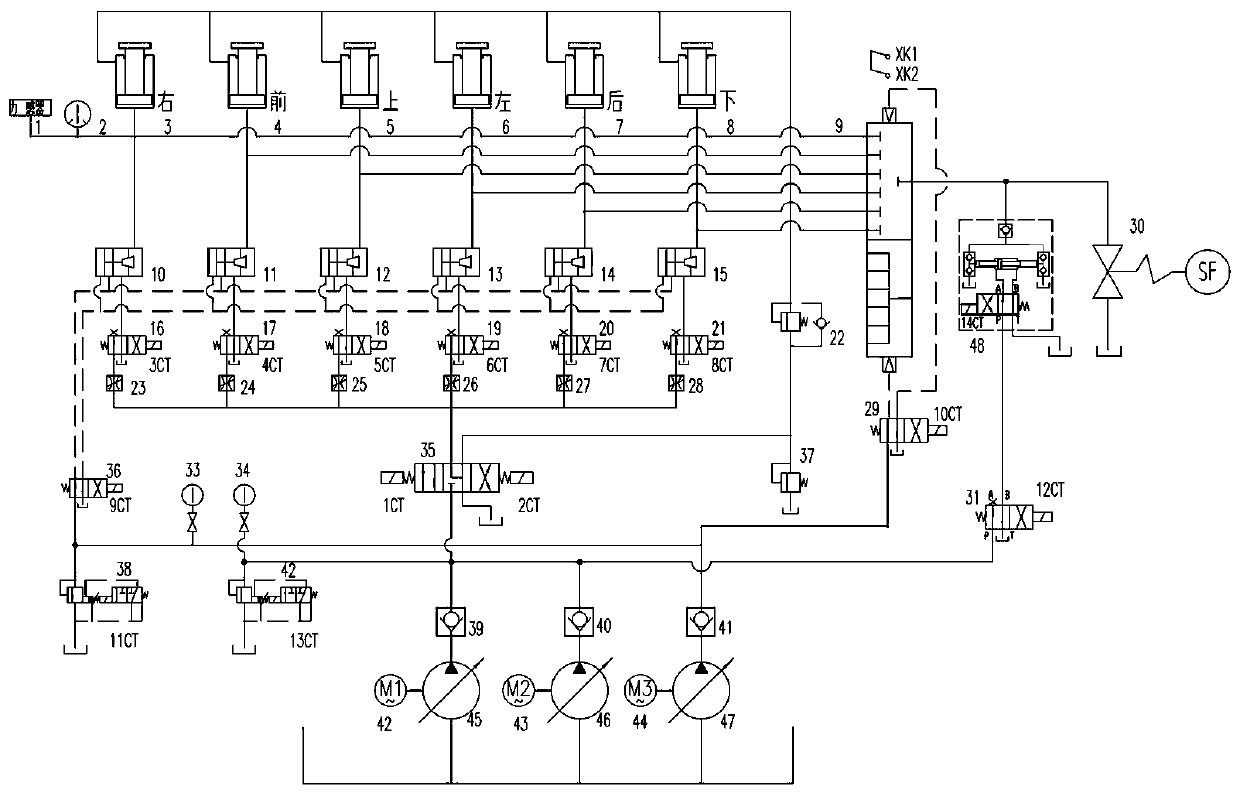

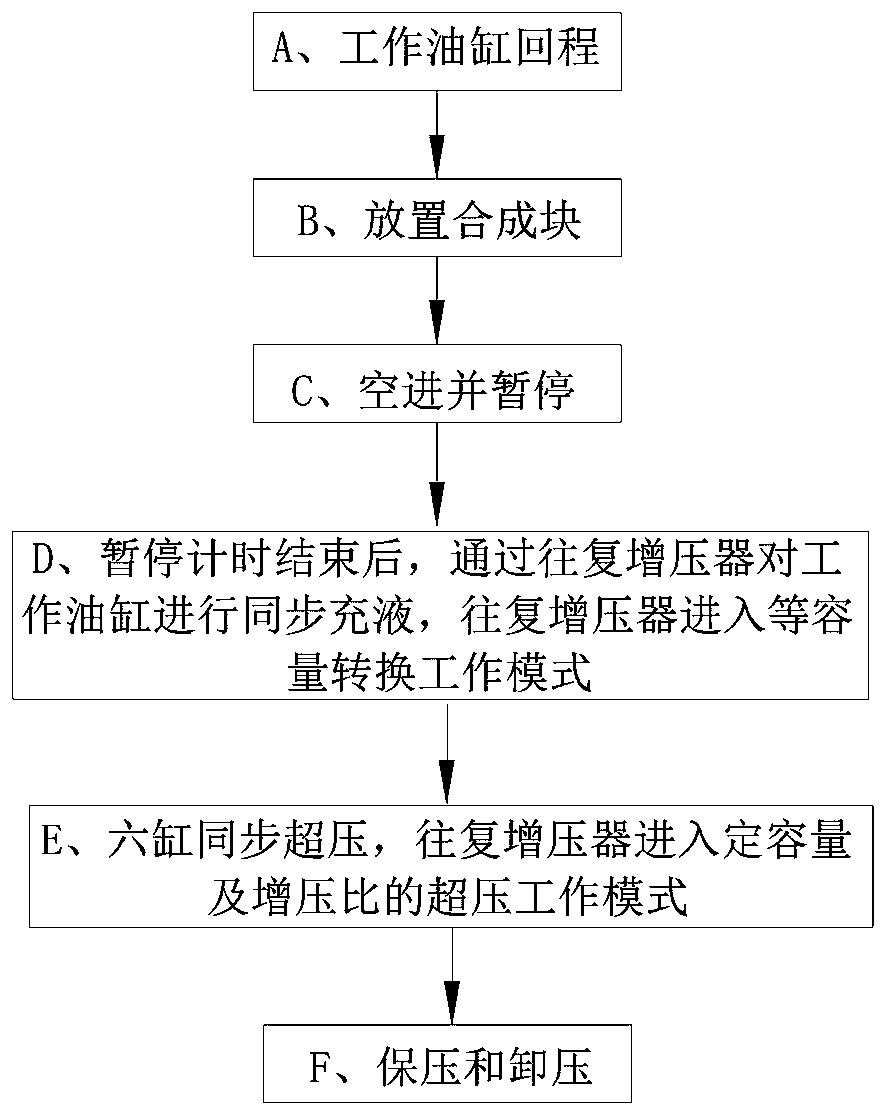

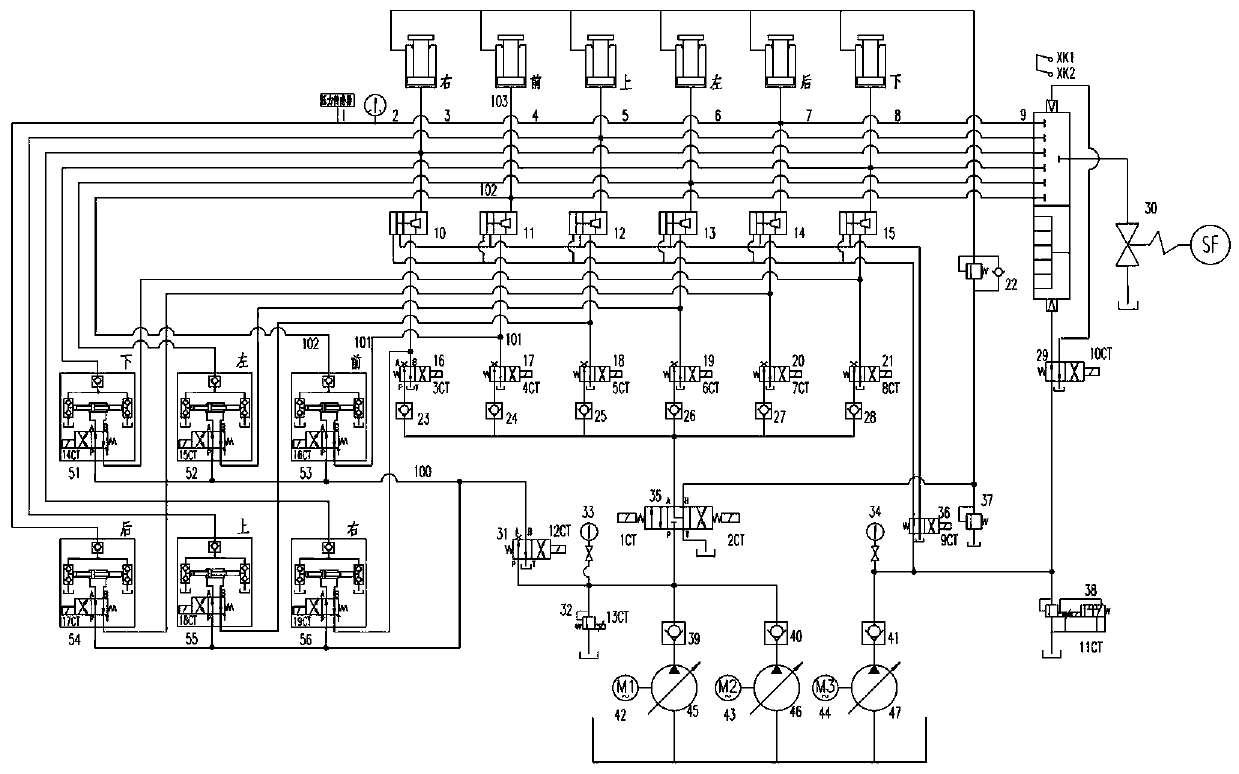

[0051] The invention discloses a synchronous control method for hydraulic oil cylinders of a six-sided top press. The hydraulic system of the six-sided top press includes six working oil cylinders, which are respectively three positioning cylinders and three moving cylinders. Correspondingly connected to the single-cylinder oil supply pipeline, the oil inlets of the six single-cylinder oil supply pipelines are respectively connected to the main oil supply pipeline, and the direction when the hydraulic oil flows to the working cylinder on the single-cylinder oil supply pipeline is sequentially provided with a single-cylinder changer. Directional valve and ultra-high pressure hydraulic control check valve; figure 2 Shown, method process of the present invention comprises the following steps:

[0052] A. Return stroke of the working cylinder: Return the pistons of the three positioning cylinders and the three moving cylinders. Among them, the pistons of the positioning cylinders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com