Automatic adaptation-connection device for oil-conveying pipeline

A technology for oil pipelines and automatic transfer, which is applied in the direction of fluid pressure actuation devices, fluid pressure actuation system components, servo motor components, etc. It can solve the problems of hydraulic pipelines, difficulties in actual operation and maintenance of crew members, and decreased fueling efficiency, etc. problems, to achieve the effect of reducing operation intensity, protecting normal operation and protecting health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

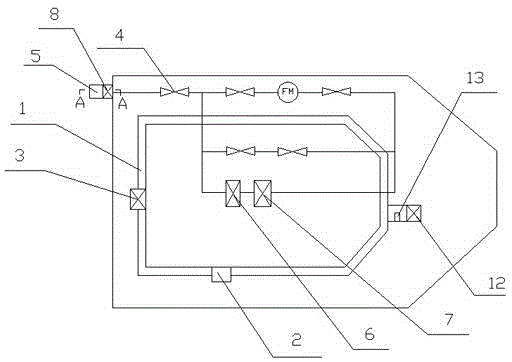

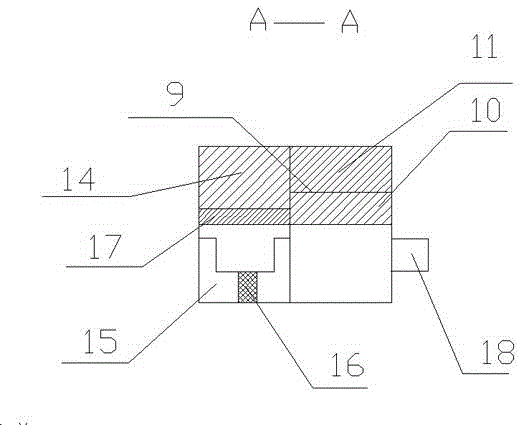

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] An automatic transfer device for an oil pipeline, comprising an oil pipeline 1 and a switch device 2, the oil pipeline 1 adopts a marine professional oil pipeline, the oil pipeline 1 is connected with an inlet and outlet valve 3, and the inlet and outlet valve 3 adopts an oil check valve, The oil delivery pipeline 1 is connected by a separate oil delivery pipeline, and a sealing device is provided between the separate oil delivery pipelines. An adapter device 2 is connected between the oil delivery pipelines 1. The adapter device 2 is a hydraulic control adapter device. The oil delivery pipeline 1 is connected with a hydraulic A hydraulic remote control valve 4 is added to the inlet and outlet of the pump 5 and the hydraulic pump 5, and the inlet and outlet are connected in series. The hydraulic remote control valve 4 is controlled by a hydraulic control unit, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com