Filtering system of far infrared electronic heating diesel filter

A diesel filter and electronic heating technology, which is applied in the direction of charging system, machine/engine, fuel heat treatment device, etc., can solve the problem of not being able to absorb diesel normally, not ensuring the normal flow of the diesel oil supply system, and easy to freeze and absorb wax and other issues to achieve the effect of increasing power, reducing wear and reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by specific embodiment in conjunction with accompanying drawing the present invention will be described in further detail:

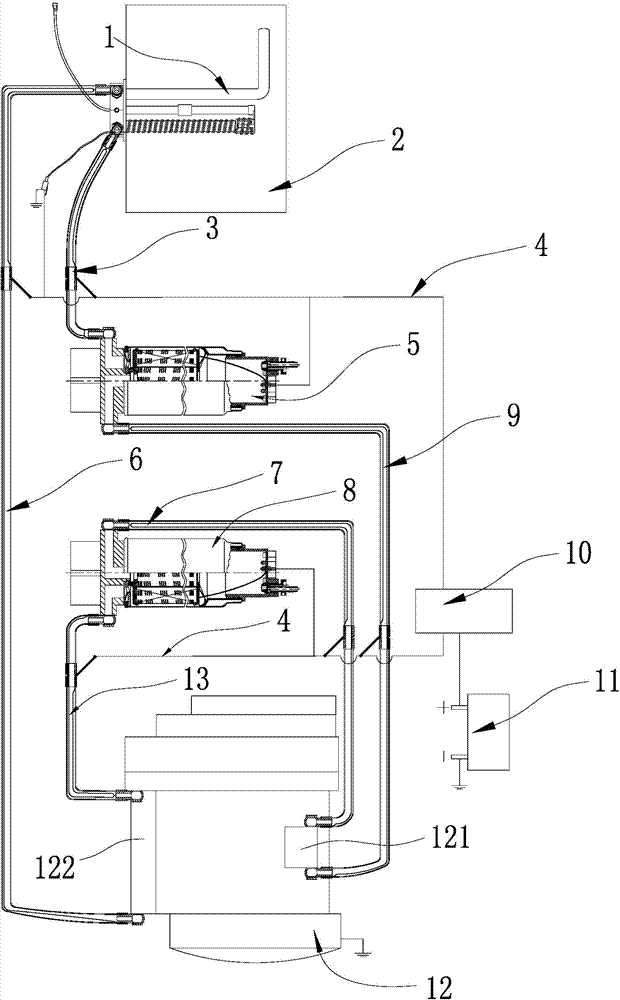

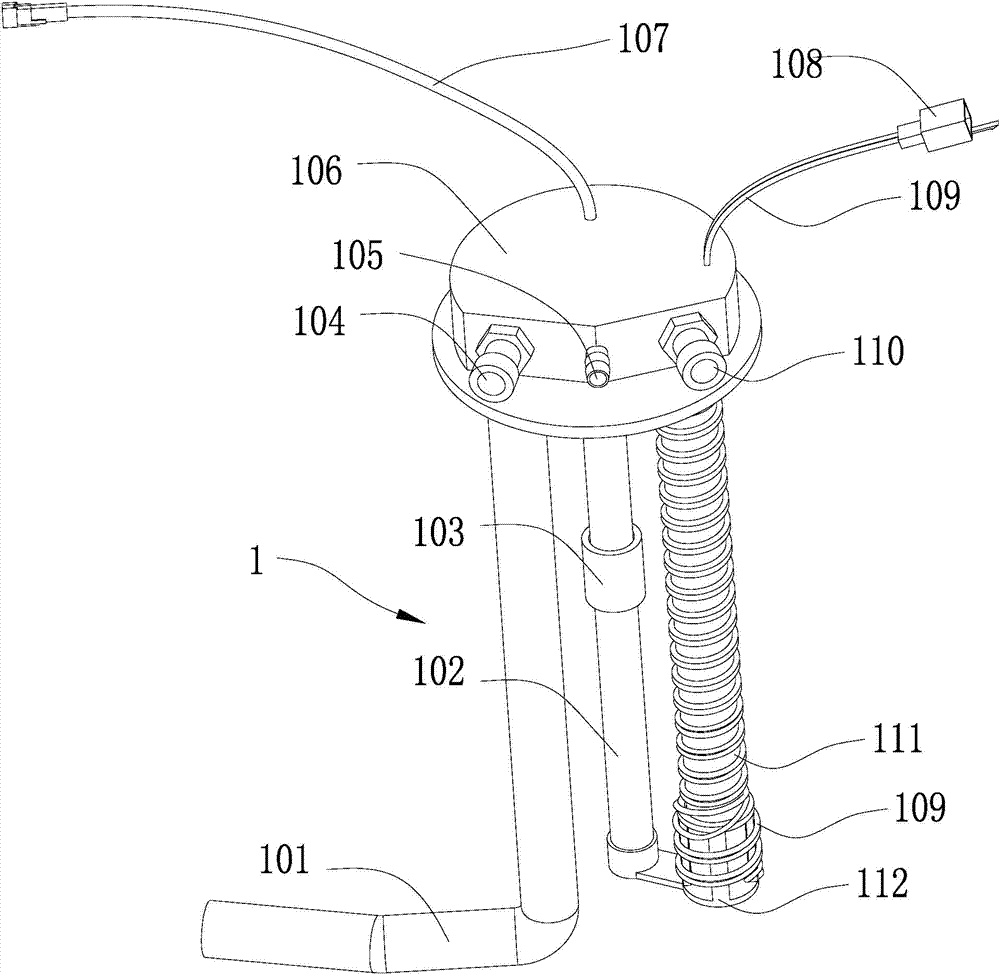

[0015] A far-infrared electronic heating diesel filter filter system, including a fuel tank 2, an engine 12, a power supply 11, five sets of heating oil pipes, two sets of heating diesel filters, a heating oil level sensor 1 and a control unit 10, in the system , Two groups of heated diesel oil filters are respectively coarse filter heated diesel filter 5 and fine filter heated diesel filter 8.

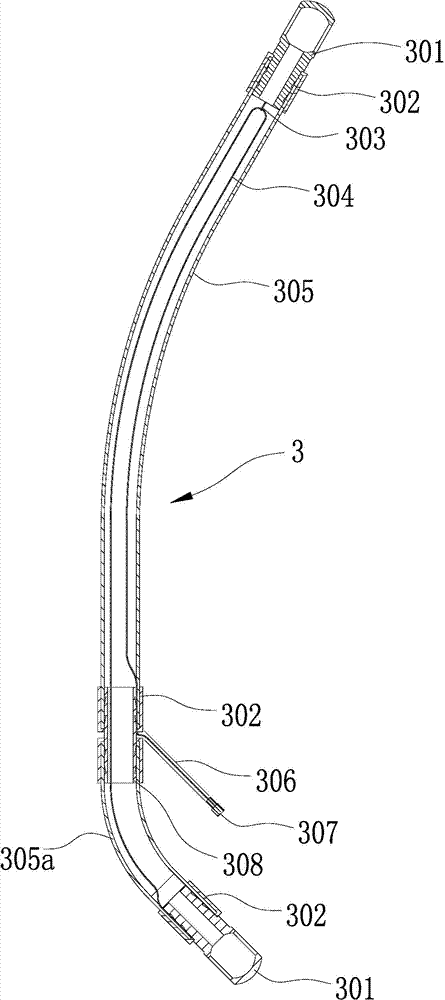

[0016] The fuel tank 2 is provided with a heating oil level sensor 1, and the engine 12 is equipped with a coarse filter heating diesel filter 5 and a fine filter heating diesel filter 8, and the heating oil level sensor 1 is connected to the coarse filter through the first heating oil pipe 3 Filtration heating diesel oil filter 5 is connected, coarse filtering heating diesel oil filter 5 is connected with the low-pressure oil pump 121 on the engine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com