Oil-gas separated-type balancing block

A balance block and separate technology, applied in the field of compressors, can solve the problem of large oil output, reduce oil output, improve heat transfer effect and energy efficiency, improve service life and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

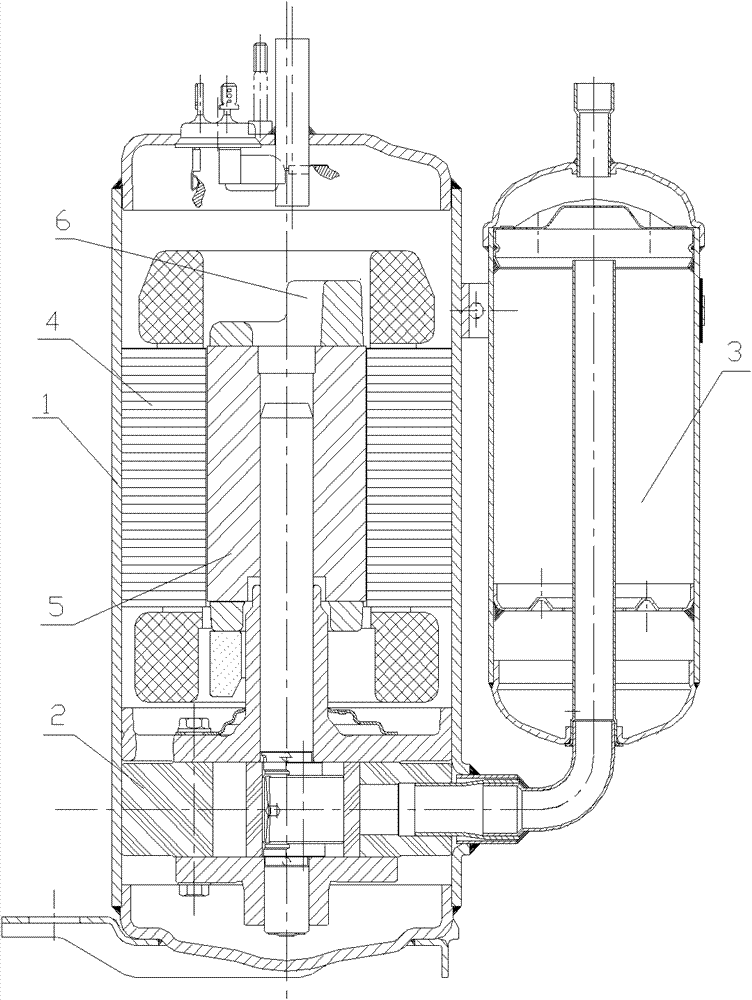

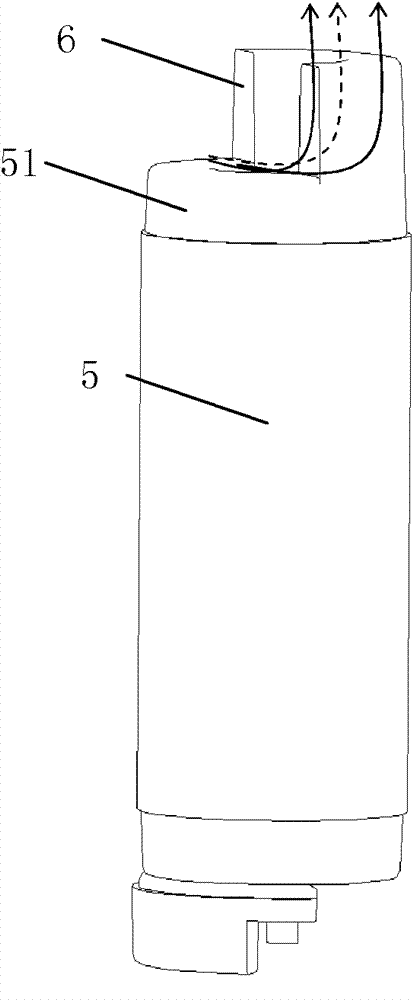

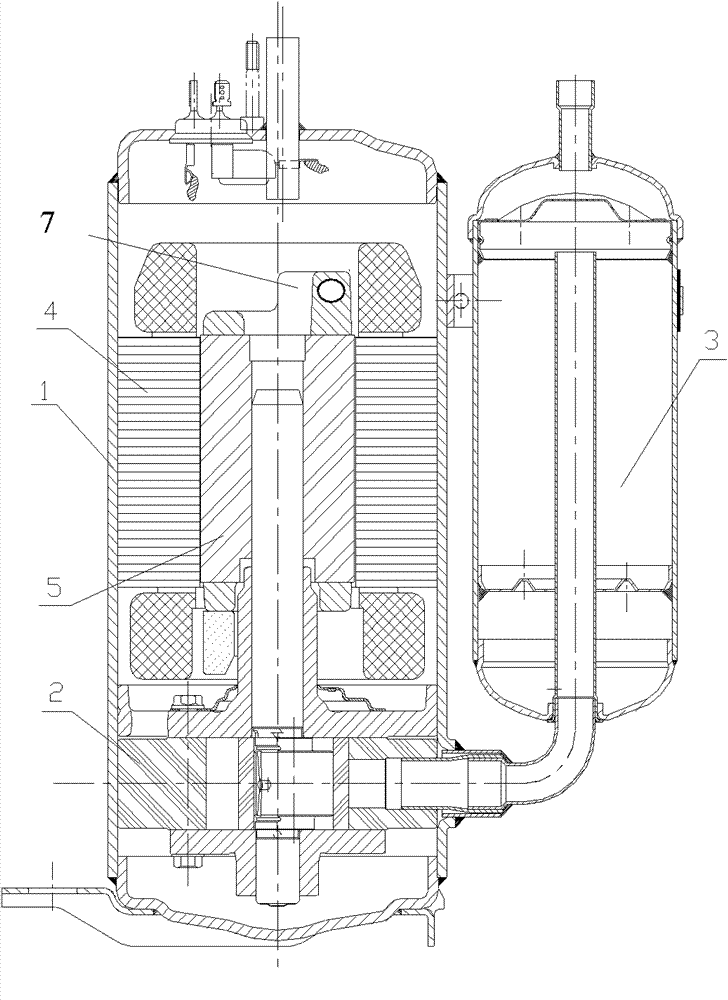

[0027] The structure of the compressor equipped with the oil-gas separation balance weight of the present invention is as follows: image 3 As shown, it includes a compressor housing 1, a pump body 2, an accumulator 3, a stator 4, a rotor 5, and the like. Such as Figure 4 , 5 As shown, the rotor 5 is composed of an iron core in the middle and end rings 51 at both ends. The end of the rotor 5 is provided with a balance weight 7, the balance weight 7 can be made of the same material (aluminum) as the end ring 51, and manufactured according to the existing manufacturing process, for example: the balance weight 7 and the end ring 51 are die-cast together; or The balance weight 7 and the end ring 51 are manufactured separately, and then assembled by stamping, welding or riveting.

[0028] Such as Figure 6 As shown, the balance weight 7 is semi-circular and includes two end faces: a windward end face and a leeward end face. The balance weight 7 is provided with a channel 71 p...

Embodiment 2

[0032] Such as Figure 7 As shown, in this embodiment, the channels 71 include two. The two passages 71 are arranged side by side up and down, respectively passing through the two end faces of the balance weight. Each channel 71 is respectively provided with more than one oil return branch 72 communicating with the outer wall surface of the balance weight 7 .

[0033] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com