Patents

Literature

45results about How to "Guaranteed oil quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

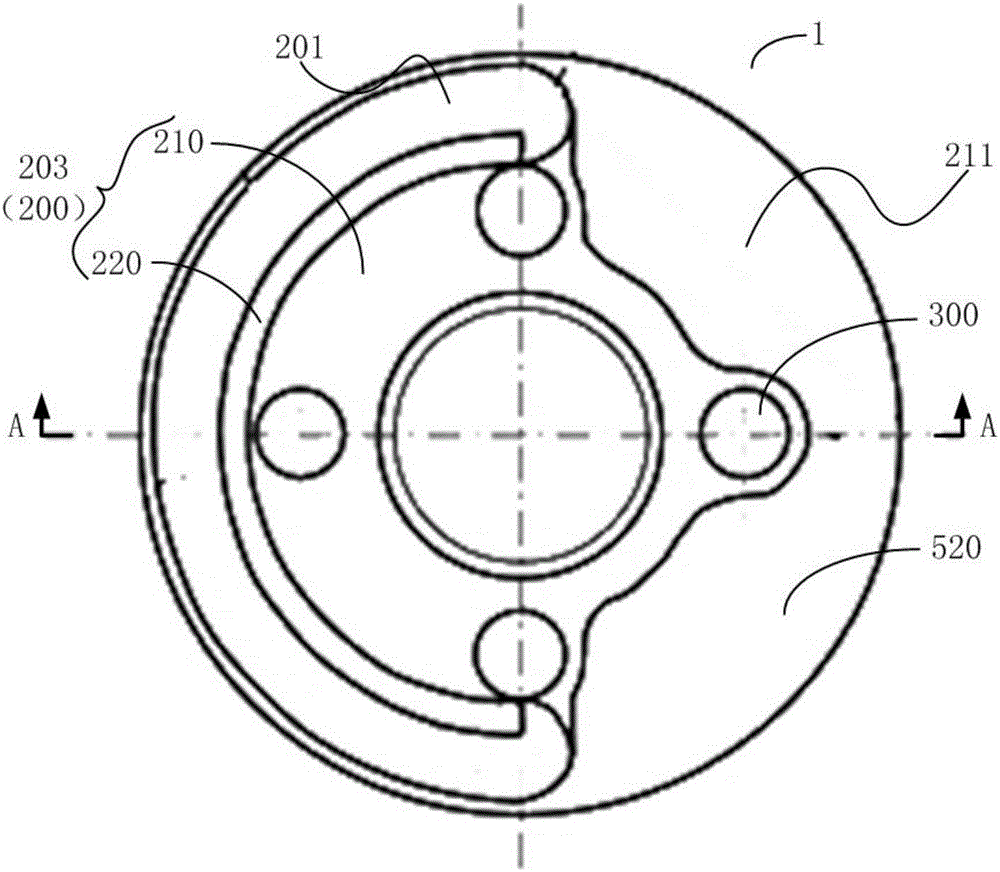

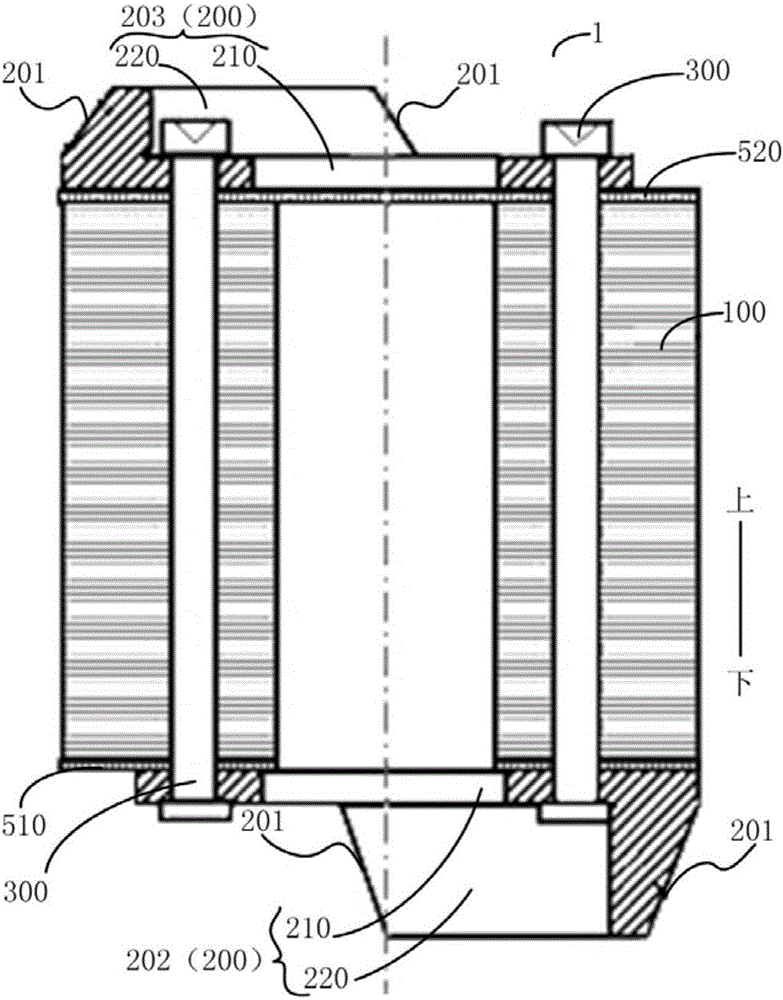

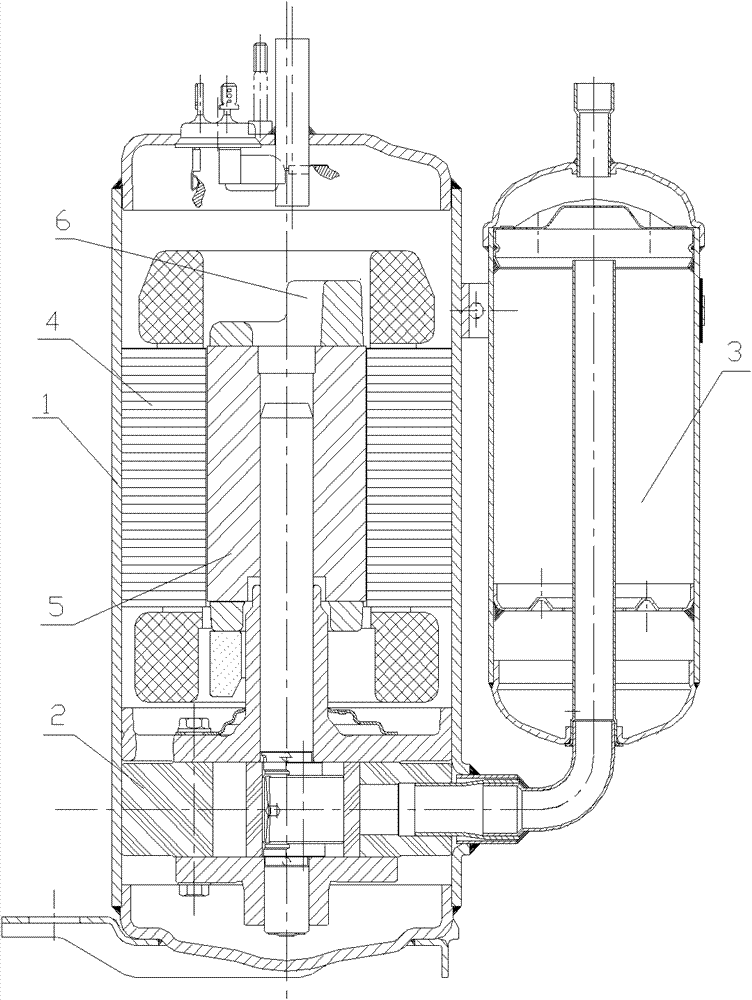

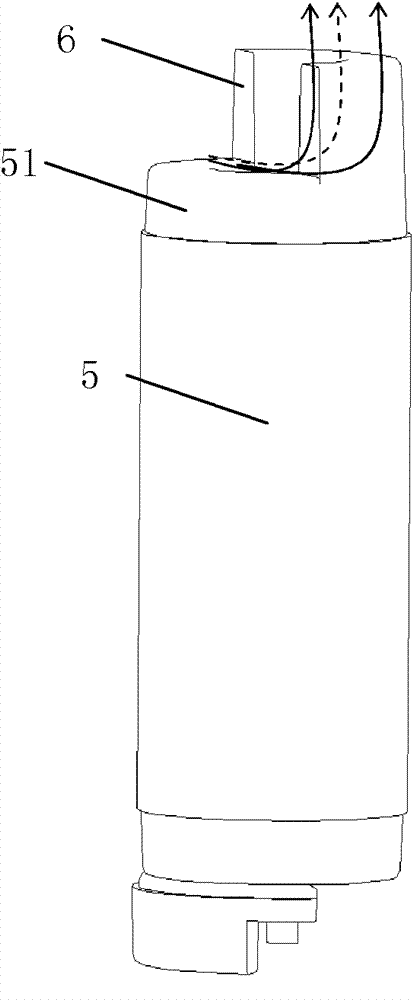

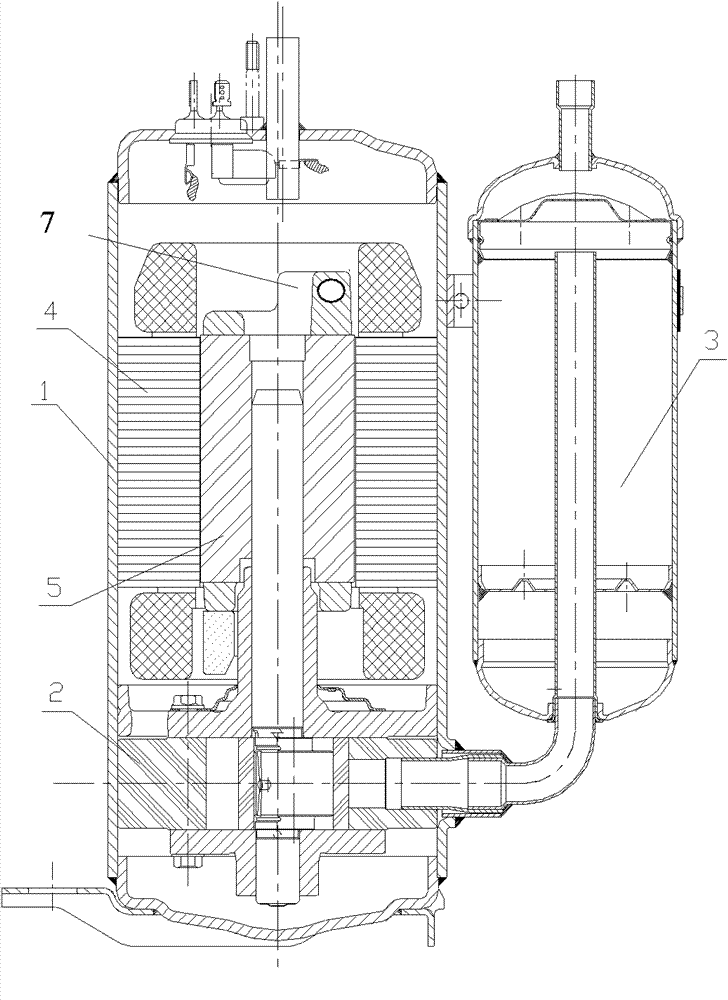

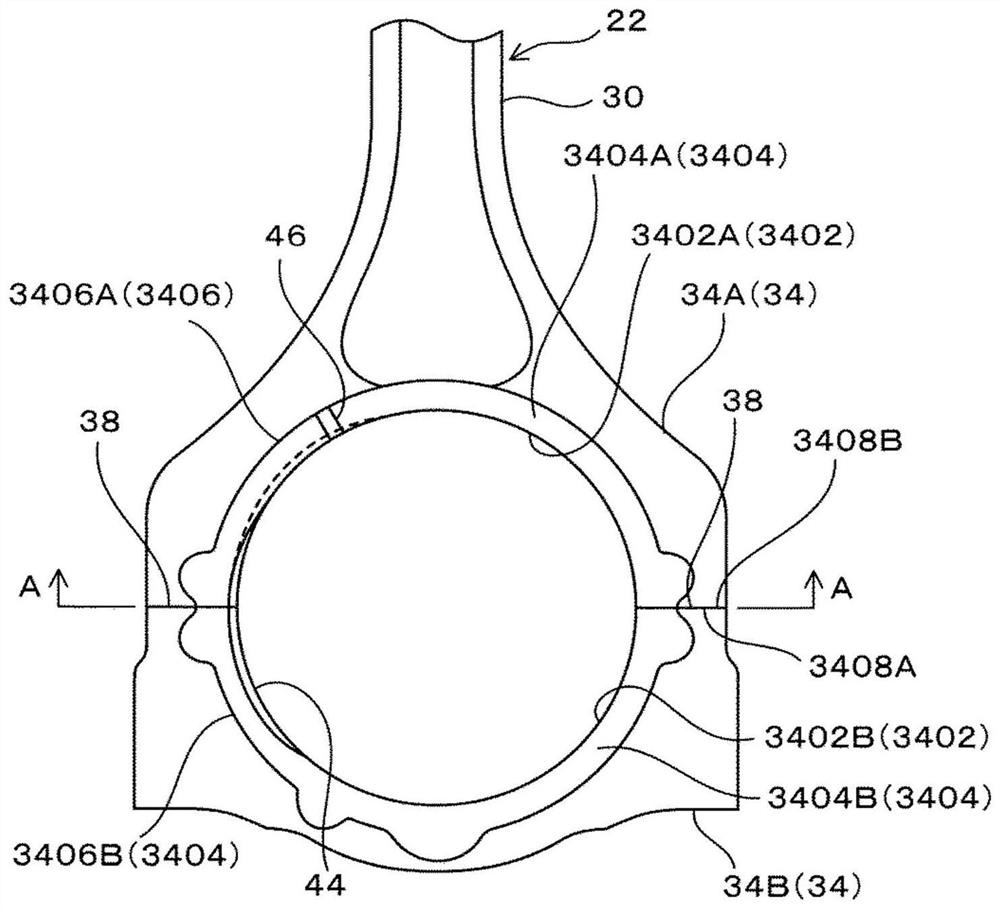

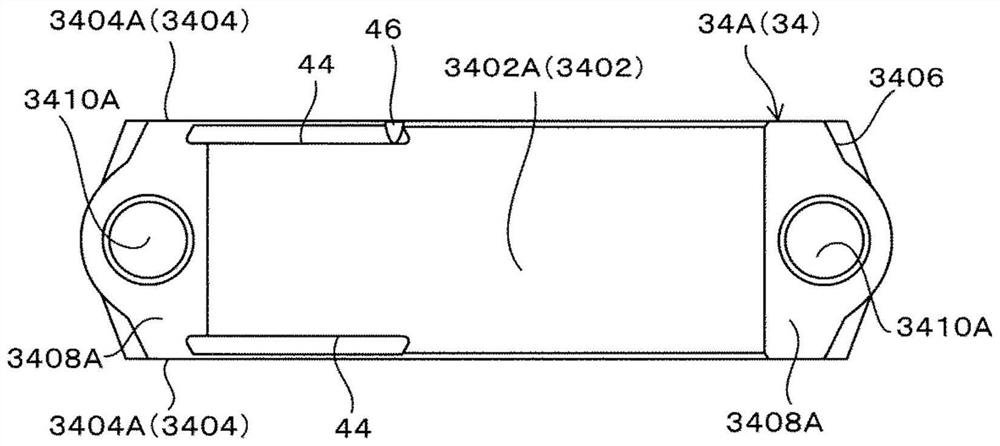

Oil-gas separated-type balancing block

ActiveCN102162454AReduce oil dischargeExtended service lifeRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringMechanical engineering

The invention discloses an oil-gas separated-type balancing block which is internally provided with a channel, wherein the channel penetrates through two end surfaces of the balancing block and is communicated with the outer side wall of the balancing block. By adopting a compressor equipped with the balancing block provided by the invention can separate refrigerating machine oil from gas refrigerant in the operation process, thus the oil discharge amount of the compressor is reduced, not only can the amount of refrigerating machine oil in the shell of the compressor be ensured, the service life and dependance of the compressor are improved, but also the heat transfer effect and energy efficiency of an air conditioner can be improved.

Owner:PANASONIC WANBAO GUANGZHOU COMPRESSOR

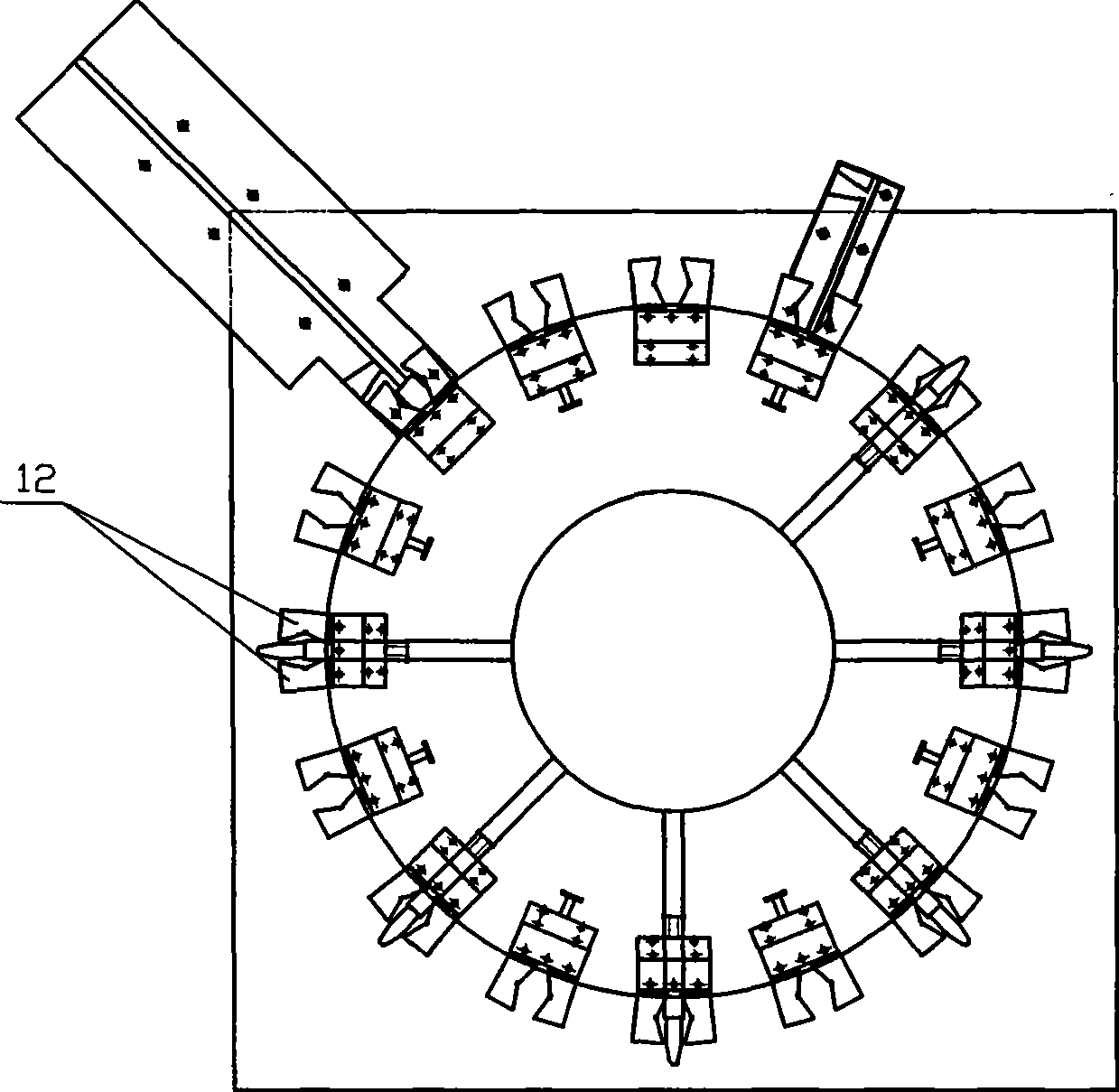

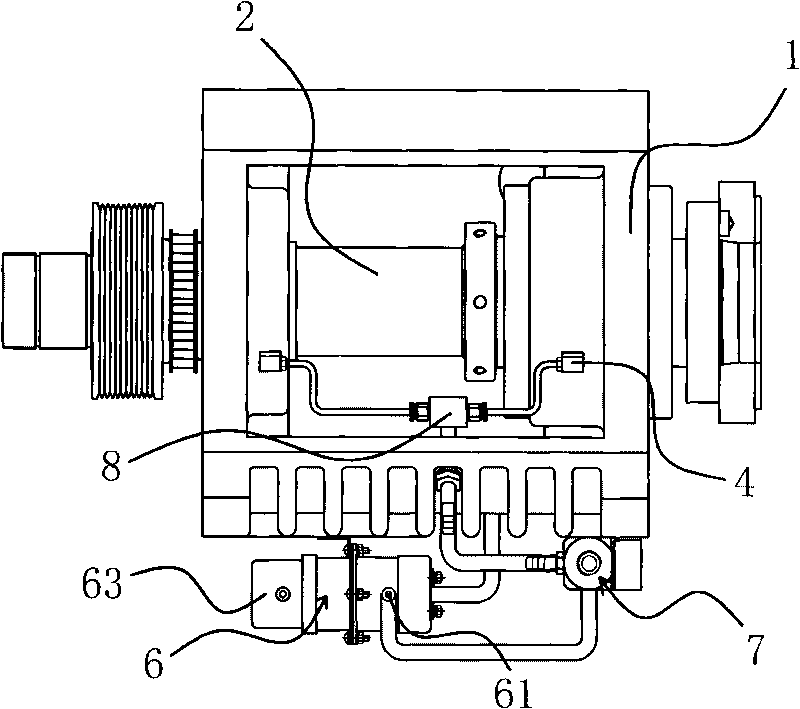

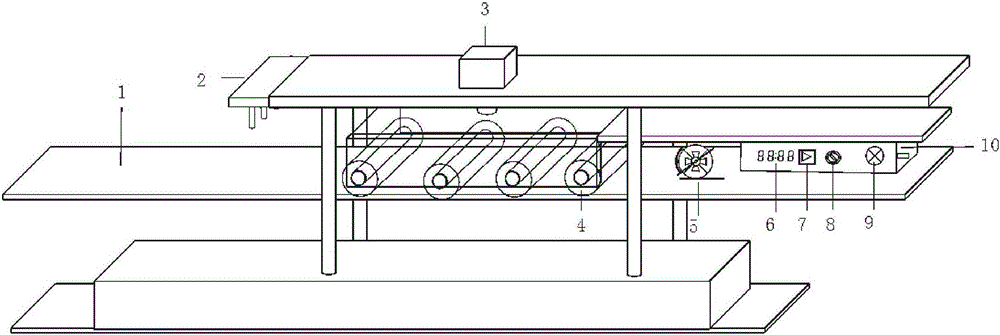

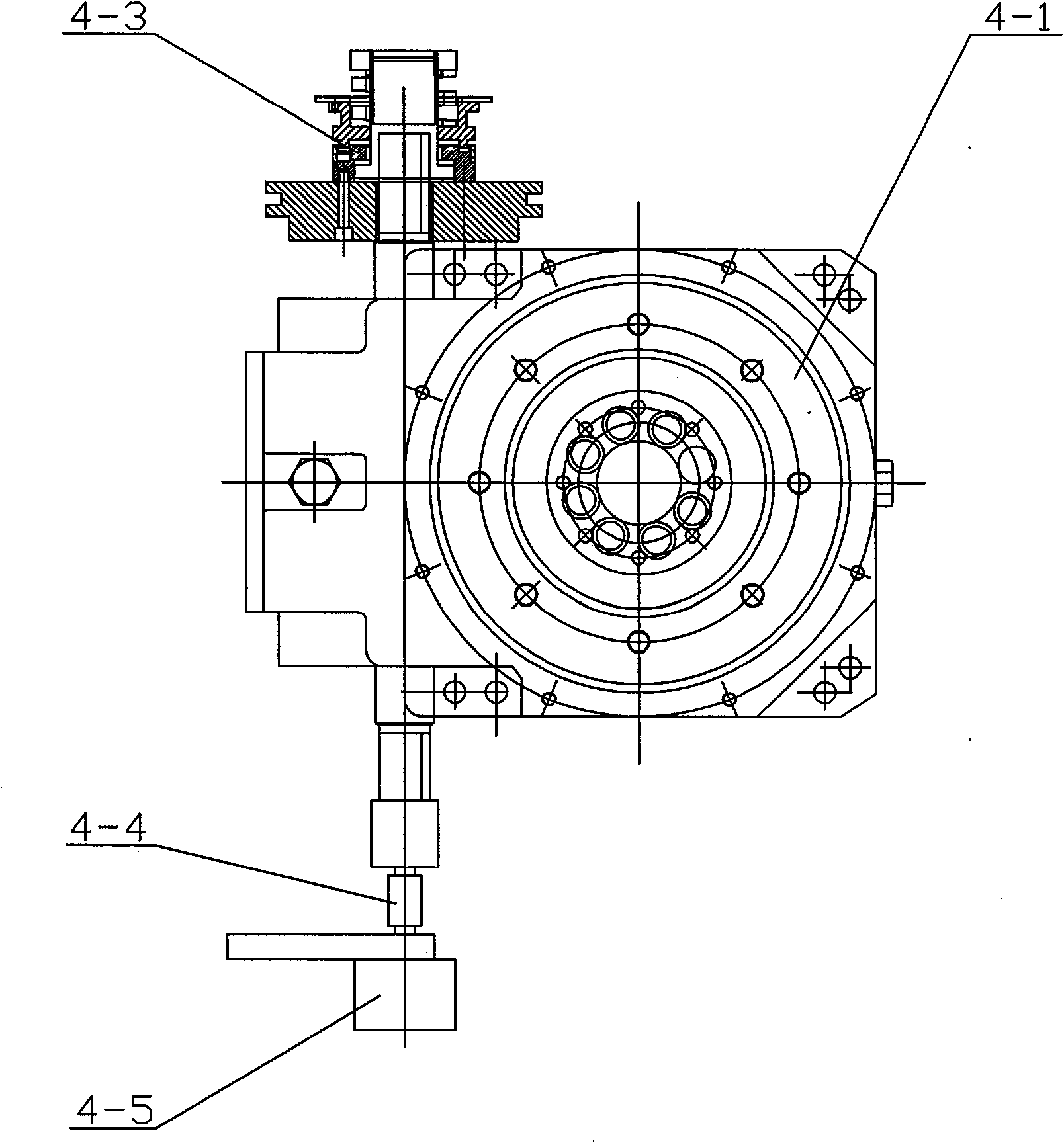

Fully automatic wax and oil mixture can packing machine

The invention discloses a fully automatic wax and oil mixture can packing machine, which mainly adopts a motor and a dividing mechanism which are fixed on a platform by bolts respectively. A first chain wheel is arranged on a main shaft of the motor; a second chain wheel is arranged on a main shaft of the dividing mechanism; and the first chain wheel and the second chain wheel are connected by a chain. The motor is connected with an energized overload clutch through the chain; and the energized overload clutch is connected with the dividing mechanism through a shaft. A clamping hand is arranged on sixteen work positions of a rotating table through the bolts respectively; and the rotating table is arranged on the dividing mechanism through a connecting flange. A round platform surface is fixed on the rotating table through the bolt; an oil filling device is fixed on the rotating table; and an oil bucket is fixed on the round platform surface through a bracket. A loading device and an unloading device are fixed on the platform through the bolts; and a coder is connected with an output shaft of the dividing mechanism through a soft connecting piece. The can packing machine can realize multi-station oil filling, and has the characteristics of compact, simple and reasonable structure, high production efficiency, exact oil filling amount, and the like.

Owner:WUXI HONGGUANG CAPACITOR

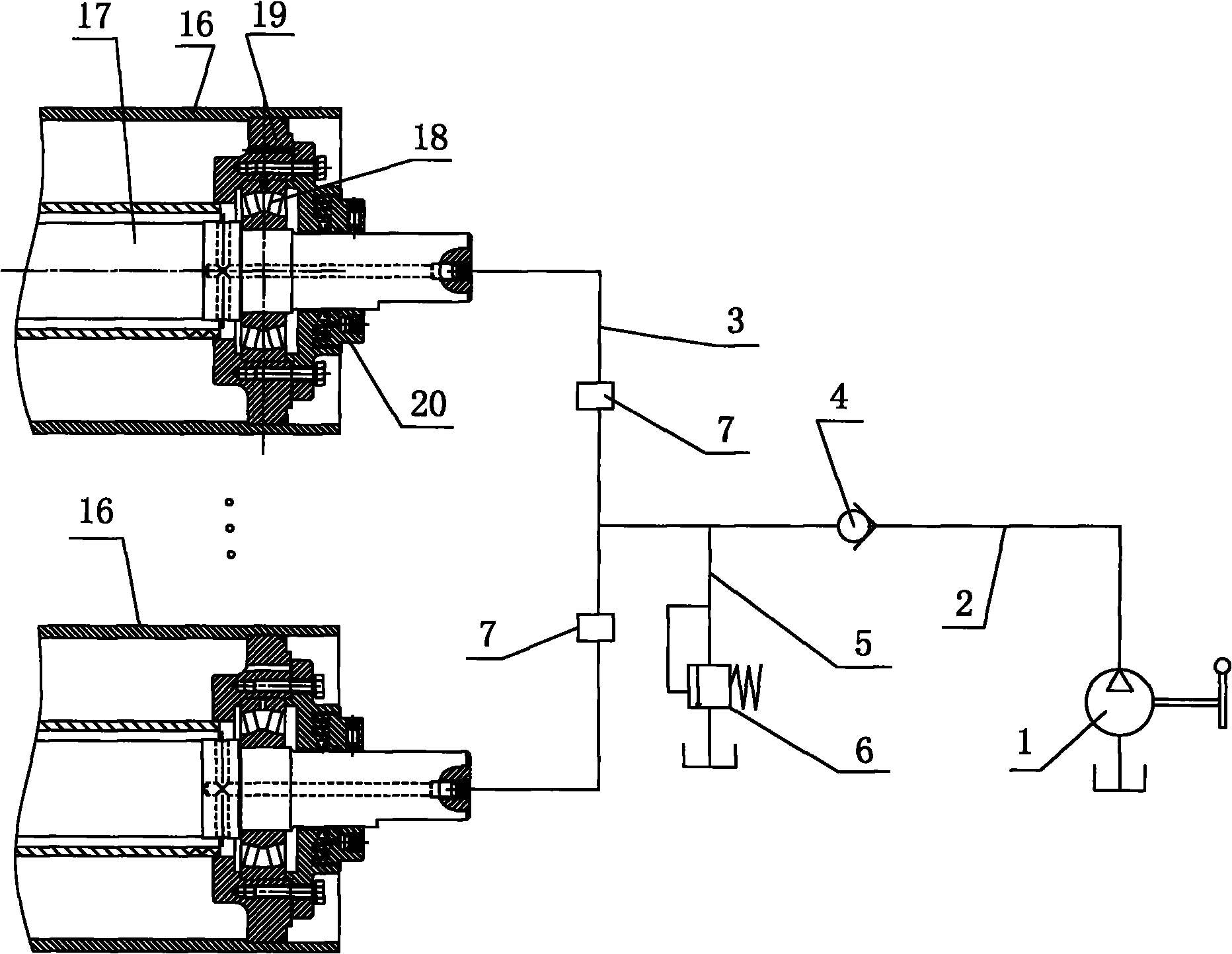

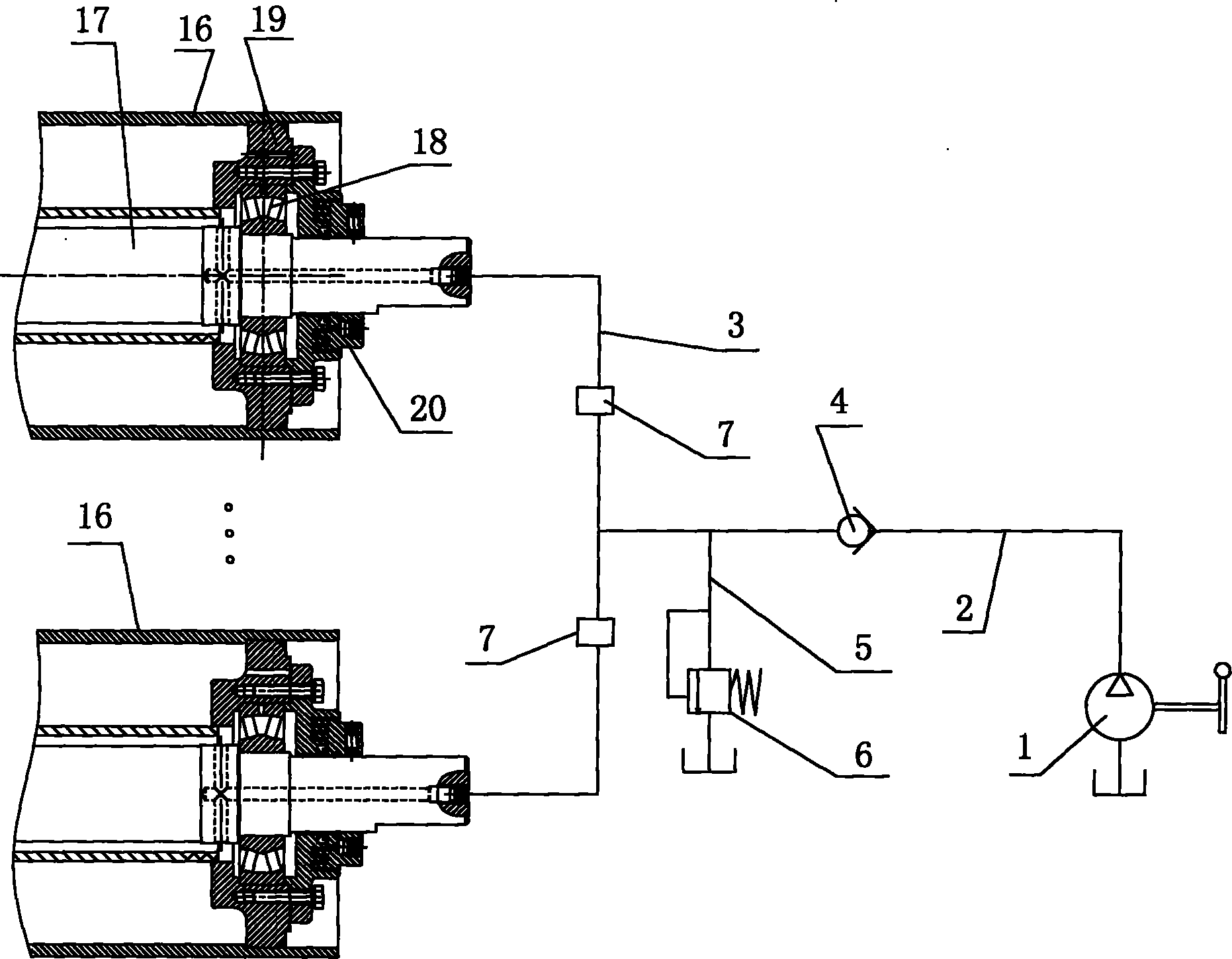

Machine head and machine tail centralized lubricating system of belt conveyor

The invention discloses a machine head and machine tail centralized lubricating system of a belt conveyor, comprising a main oil supply pipeline, a lubricant pump, a one-way valve, a plurality of oil supply branches, a plurality of oil feed distributors, an oil return pipeline and an overflow valve, wherein the lubricant pump continuously injects lubricating grease inside an oil storage tank into the main oil supply pipeline; the one-way valve is arranged on the main oil supply pipeline; the plurality of oil supply branches are respectively connected with an oil outlet of the main oil supply pipeline; the plurality of oil feed distributors are respectively arranged on the plurality of oil supply branches; the oil return pipeline is communicated with the main oil supply pipeline; the overflow valve is arranged on the oil return pipeline; an oil inlet of the main oil supply pipeline is connected with an oil injection orifice of the lubricant pump; the oil outlets of the plurality of oil supply branches are connected with the lubricating positions of the machine head and the machine tail of the belt conveyor, wherein the lubricating positions need to be lubricated; and the oil outlet of the oil return pipeline is connected into the oil storage tank. The invention has the advantages of reasonable design, easy operation, safe and reliable work and good lubricating effect, can also realize the centralized lubrication of a plurality of lubricating points and effectively overcomes the defects and the shortages of nonuniform and discontinuous lubrication, poor lubricating reliability, low lubricating efficiency, and the like of the traditional lubrication mode.

Owner:SHAANXI PUBAI SANTONG

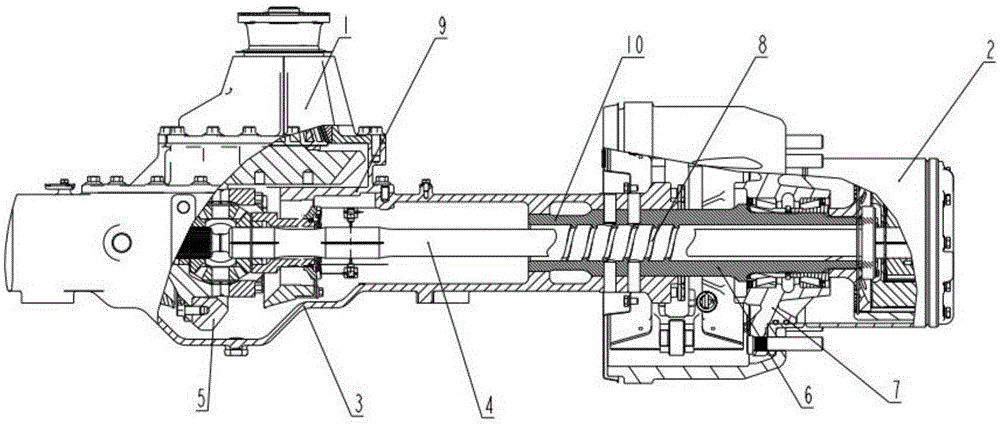

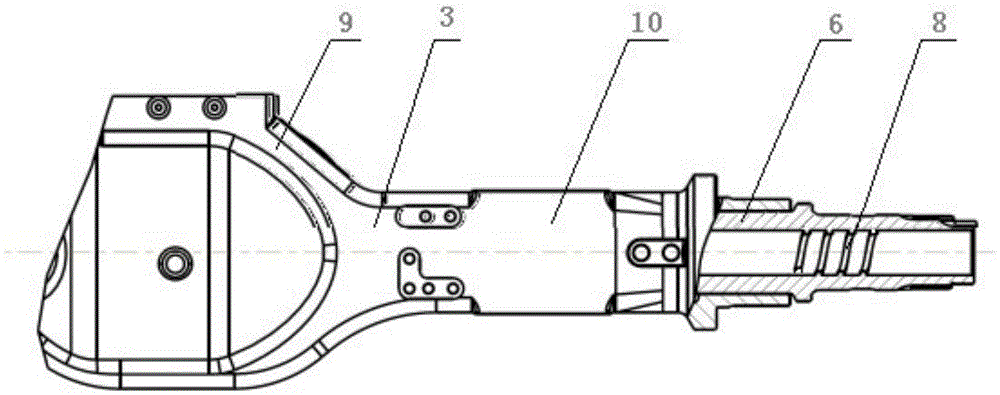

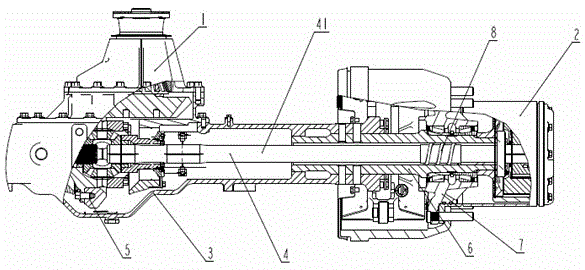

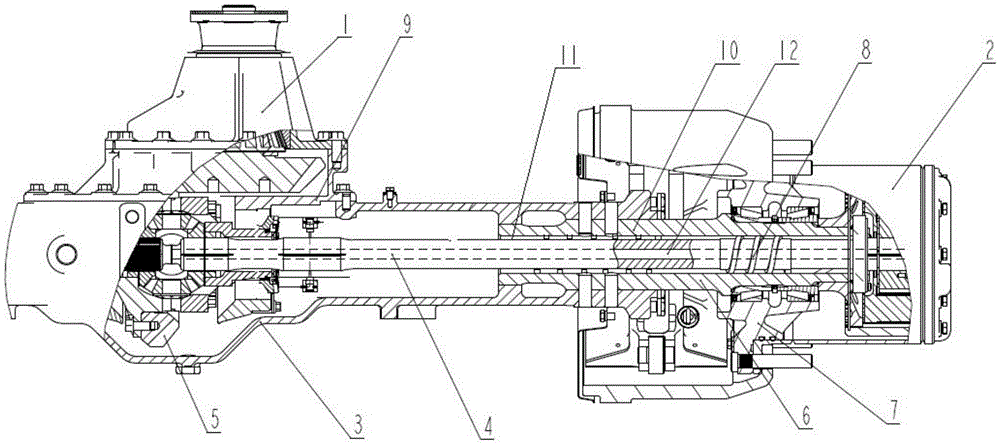

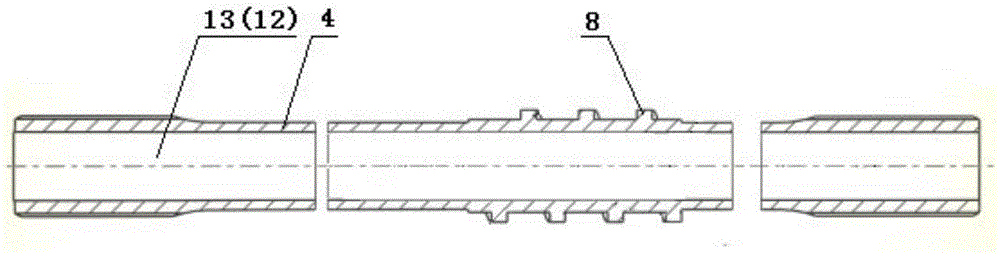

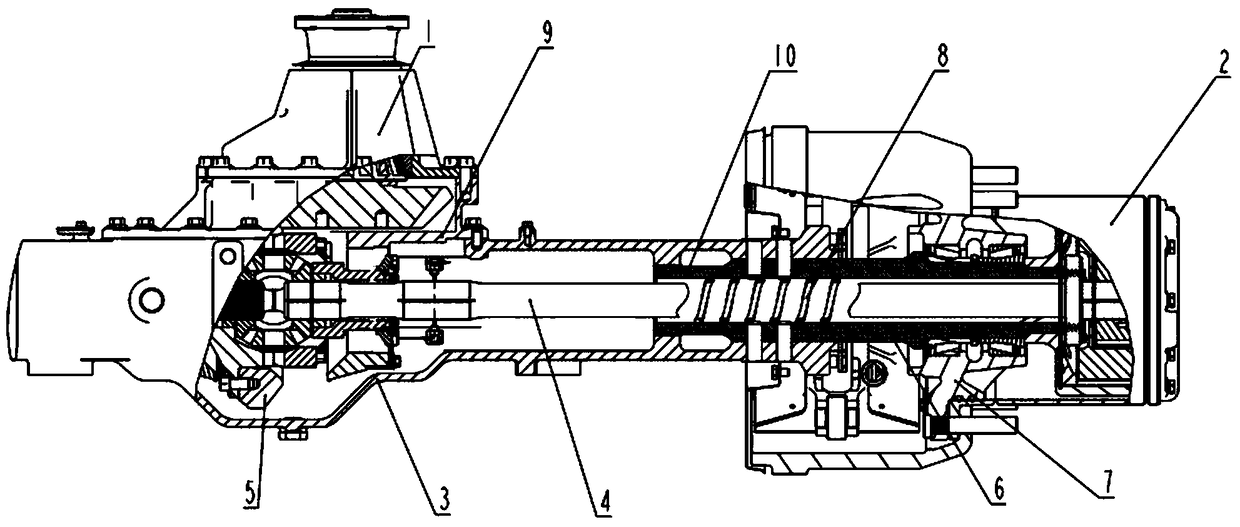

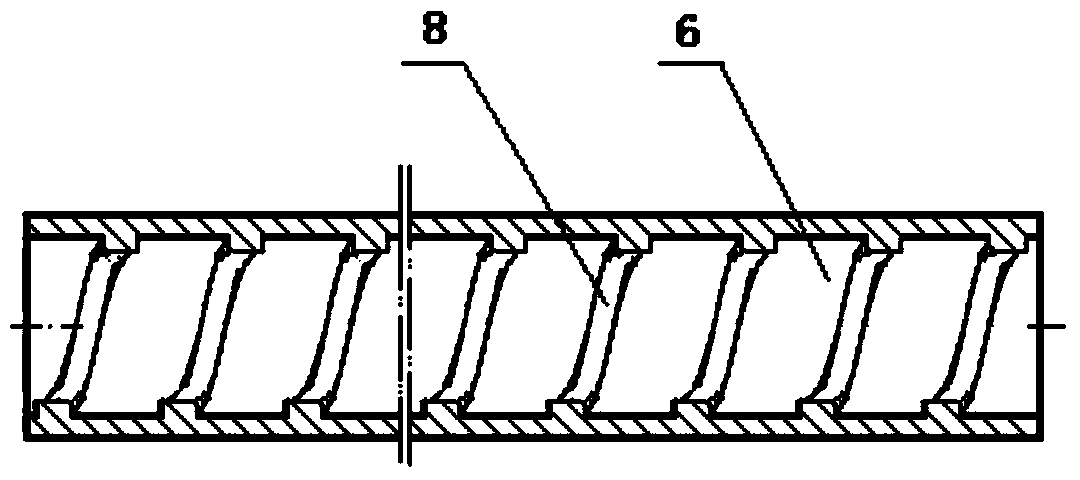

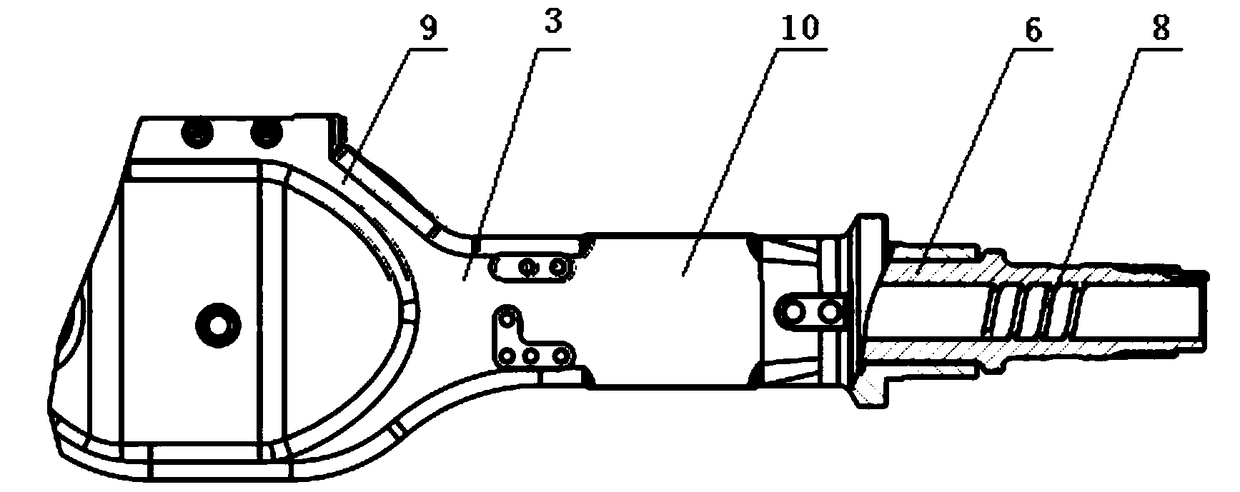

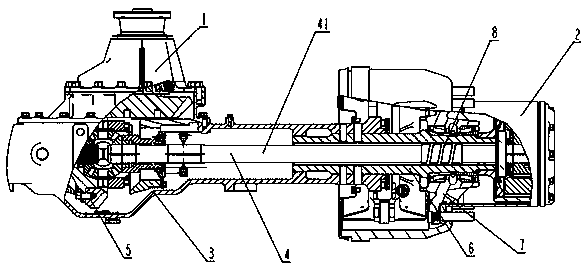

Driving axle shell

Disclosed is a driving axle shell. The driving axle shell comprises an axle shell body, a main speed reducer shell (9) and axle tube parts (10). The axle shell body and the main speed reducer shell (9) are arranged in the middle, and the axle tube parts (10) are arranged at the two ends correspondingly. A half axle (4) can be installed in an inner hole of each axle tube part (10). The surface of the inner hole of each axle tube part (10) is provided with a spiral structure (8). Each spiral structure (8) is a single-head or multiple-head spiral flange or spiral groove. In addition, when the half axles (4) installed in the inner holes of the axle tube parts (10) rotate in order to drive a wheel hub (7) and a vehicle to go forwards, the direction of lubricating oil conveying through the spiral structures (8) points to one side of a main speed reducer (1). The structure is simple, the design is novel, and manufacturing is simple and convenient. The oil quantity in all cavities can be kept stable, sufficient lubrication of all components is ensured, and oil gas discharging and cooling effects on a wheel end mechanism (2) are particularly good. The service life of a driving axle system is effectively prolonged, and the driving axle shell can be suitable for all driving axles of which the wheel end mechanisms adopt oil lubrication.

Owner:DONGFENG COMML VEHICLE CO LTD

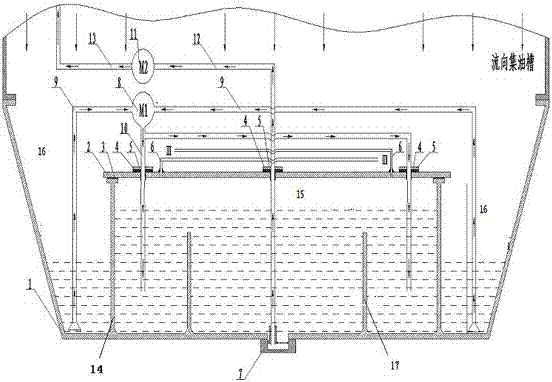

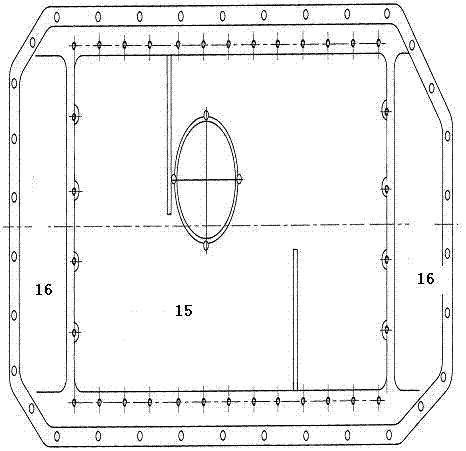

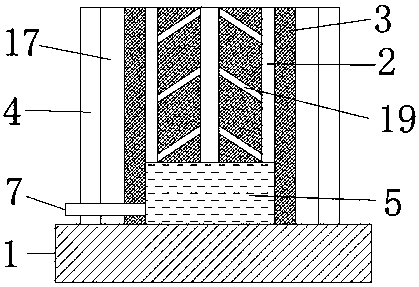

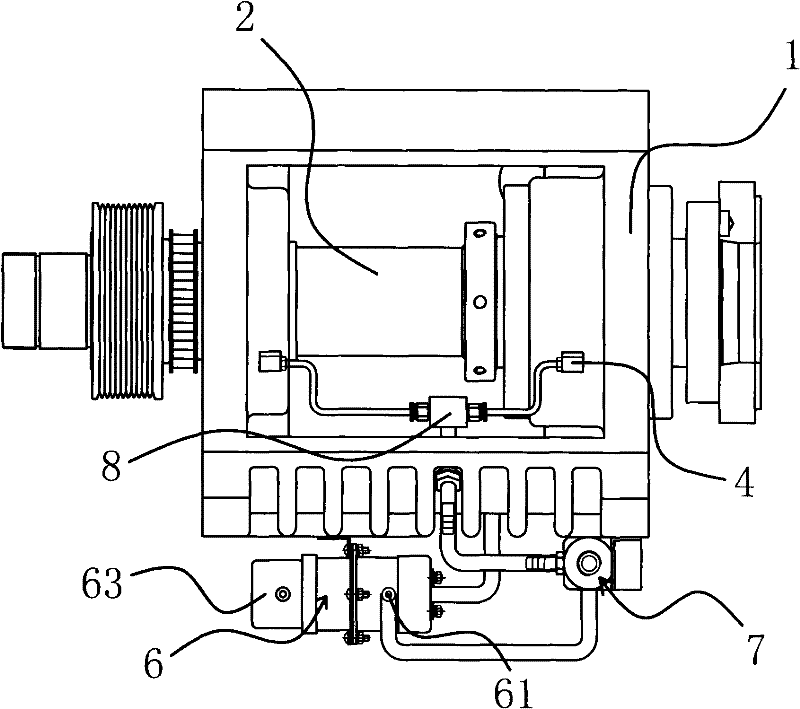

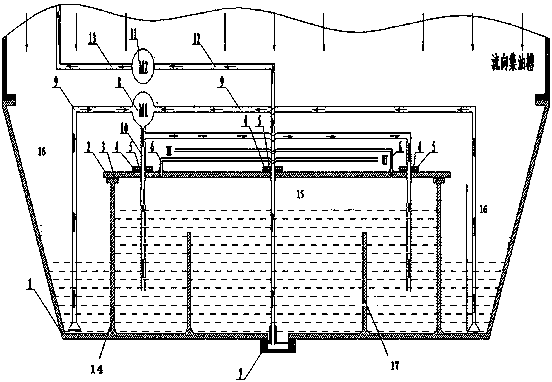

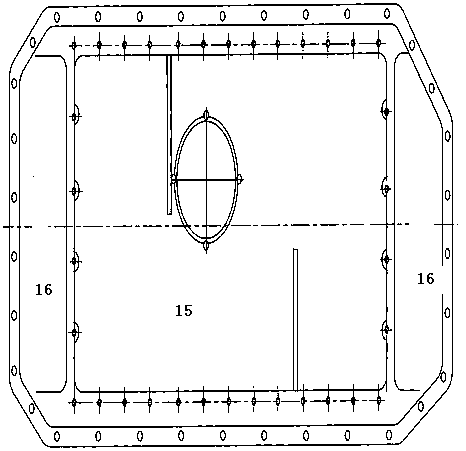

Dry type oil pan oil supply device applicable to large-inclination-angle diesel engine

ActiveCN107191240ASolve the situation that can not be lubricated normallyIncrease working inclinationOilsumpsMachines/enginesGear pumpCombustion

The invention belongs to the internal field of internal combustion engines and provides a dry type oil pan oil supply device applicable to a large-inclination-angle diesel engine. According to the dry type oil pan oil supply device applicable to the large-inclination-angle diesel engine, two partition plates perpendicular to the bottom face of a dry type oil pan are arranged at the bottom of the dry type oil pan; an oil storing groove is formed between the two partition plates, and the two sides of the oil storing groove are each provided with an oil collecting groove of an open structure; an oil inlet pipe is arranged in each oil colleting groove; the flange ends of the oil inlet pipes are connected with an oil inlet of a two-stage parallel connection gear pump; one end of an oil outlet pipe arranged in the oil storing groove stretches out of the oil storing groove and is connected with an oil outlet of the two-stage parallel connection gear pump; the dry type oil pan oil supply device is further provided with an oil sucking pipe communicated with an engine oil pump of a diesel engine lubricating system; and the other end of the oil sucking pipe is connected with a suction filter located at the bottom of the oil storing groove in an inserted connection manner. The dry type oil pan oil supply device applicable to the large-inclination-angle diesel engine effectively solves the problem that under the conditions that the speed change and the inclination are large during turning of the diesel engine, normal lubrication of the diesel engine cannot be achieved, and the inclination angle of work of the diesel engine is greatly improved.

Owner:HENAN DIESEL ENGINE IND

Lubricating device of head stock in universal machine tool

InactiveCN101700634AAvoid wastingIncrease profitMaintainance and safety accessoriesDrive shaftEngineering

The invention provides a lubricating device of a head stock in a universal machine tool, belonging to the field of mechanical technology. The lubricating device solves the problems that the existing lubricating device of the head stock can not recycle lubricating oil, and is complicated in the operation of lubricating process and low in working efficiency. In the lubricating device of the head stock in the universal machine tool, the head stock comprises a box body, a transmission shaft which is fixed on the box body along the axial direction and can rotate along the circumferential direction, and a plurality of bearings positioned between the box body and the transmission shaft; the lubricating device is arranged on the box body and comprises a plurality of oil inlet holes which are arranged on the box body and communicated with the positions where the bearings are arranged, and an oil return hole that is arranged on the box body and leads the lubricating oil to be recycled; and an oil supply mechanism is arranged between the oil inlet holes and the oil return hole. The lubricating device has the characteristics of recycling lubricating oil as well as being high in lubrication utilization rate and good in lubrication effect.

Owner:玉环时代经典机床有限公司

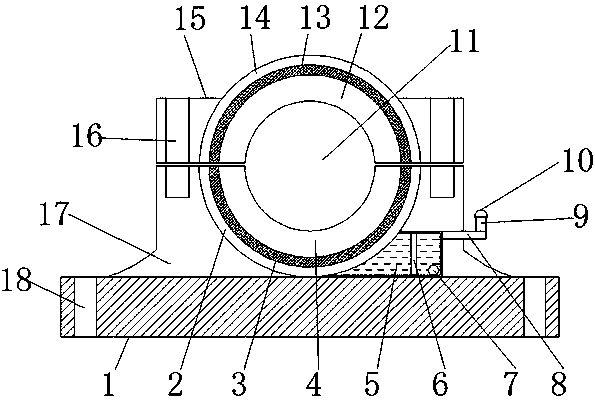

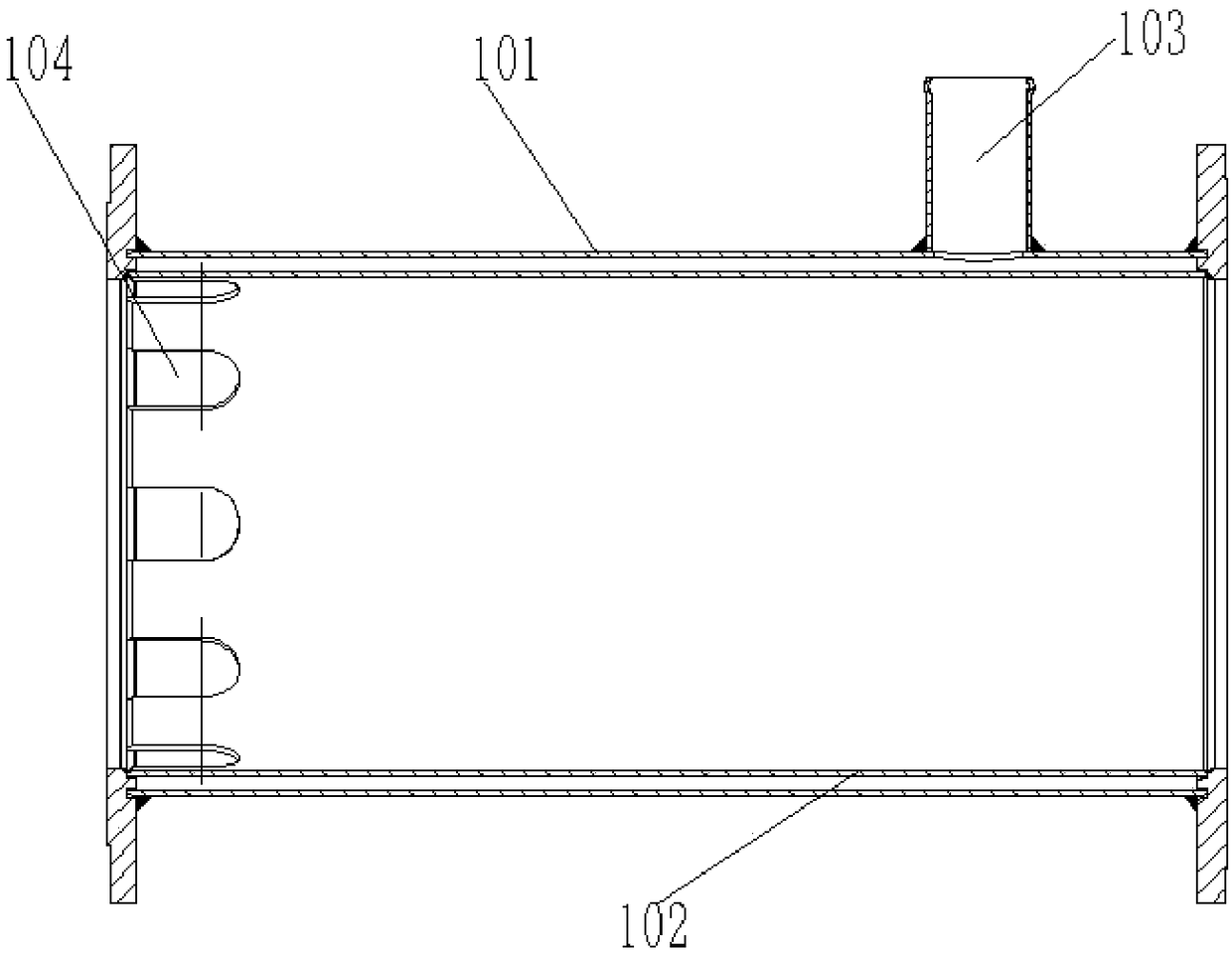

Lubricating oil conveniently injected bearing pedestal

InactiveCN107781305AObserve the amount of oilGuaranteed oil quantityLubrication elementsBearing unit rigid supportLubricationLubricant

The invention discloses a bearing seat convenient for injecting lubricating oil, comprising a seat cover, an upper bearing groove is opened on the top inner wall of the seat cover, and an upper annular oil groove is opened on the inner wall of the upper bearing groove, the inner wall of the upper annular oil groove is There is an arc-shaped oil groove, the outer walls of both sides of the seat cover are welded with limit rings, and the four corners of the outer wall of the top end of the seat cover are provided with joint screw holes, and the joint screw holes are connected with the top outer wall of the lower seat by bolts. A lower bearing groove is provided, and a lower annular oil groove is provided on the inner wall of the lower bearing groove. The present invention adds an oil storage box, and adds oil pipes and oil injection nozzles on the oil storage box, so that lubricating oil can be easily injected into the oil storage box without stopping the machine, and an observation window is added, which is conducive to observing the oil volume in the oil storage box and ensuring The amount of lubricating oil ensures the lubricating degree of the bearing, and increasing the annular oil groove and arc oil groove is conducive to the speed of lubricating oil diffusion and improves the use efficiency of lubricating oil.

Owner:响水县冠龙轴承座制造有限公司

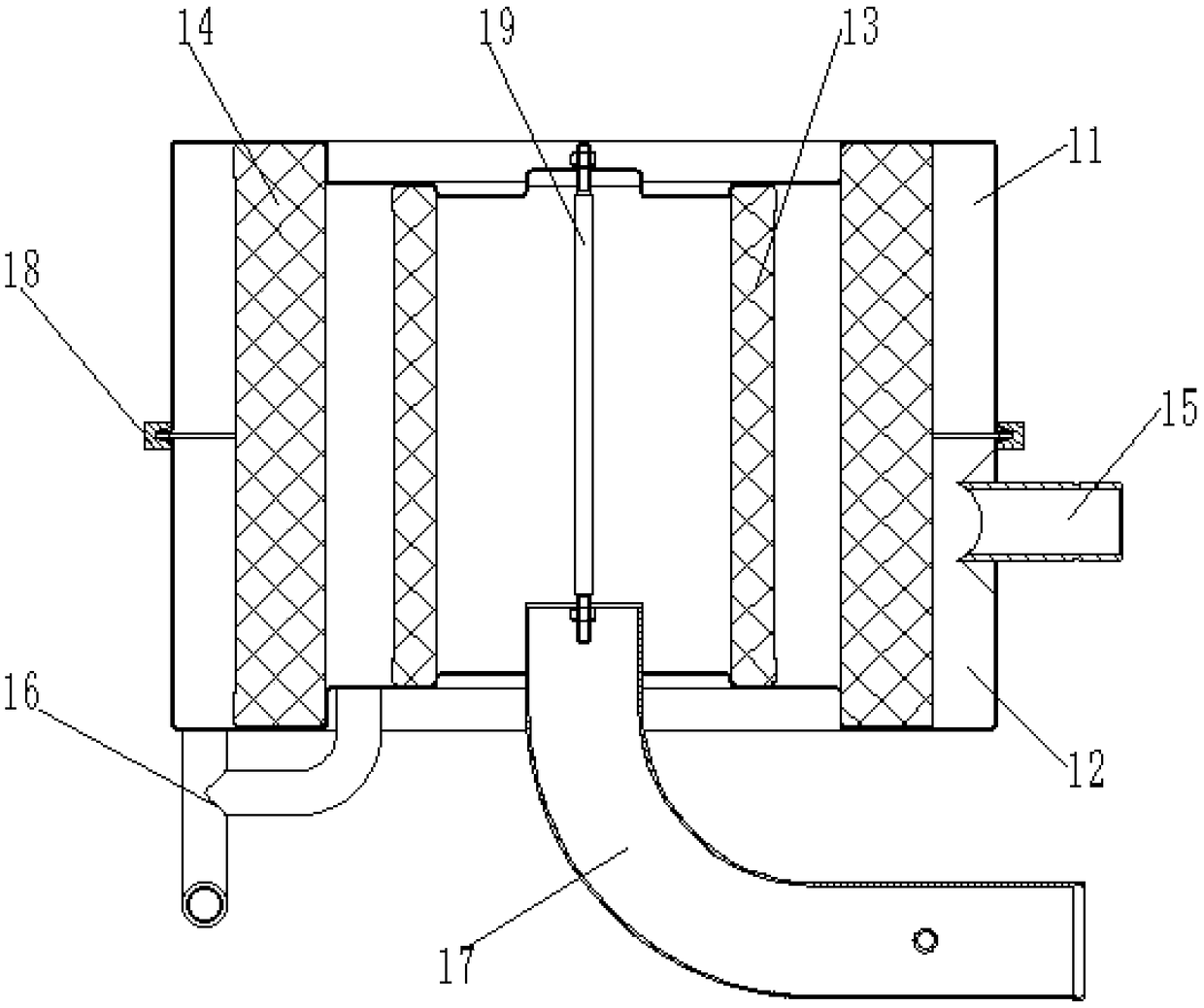

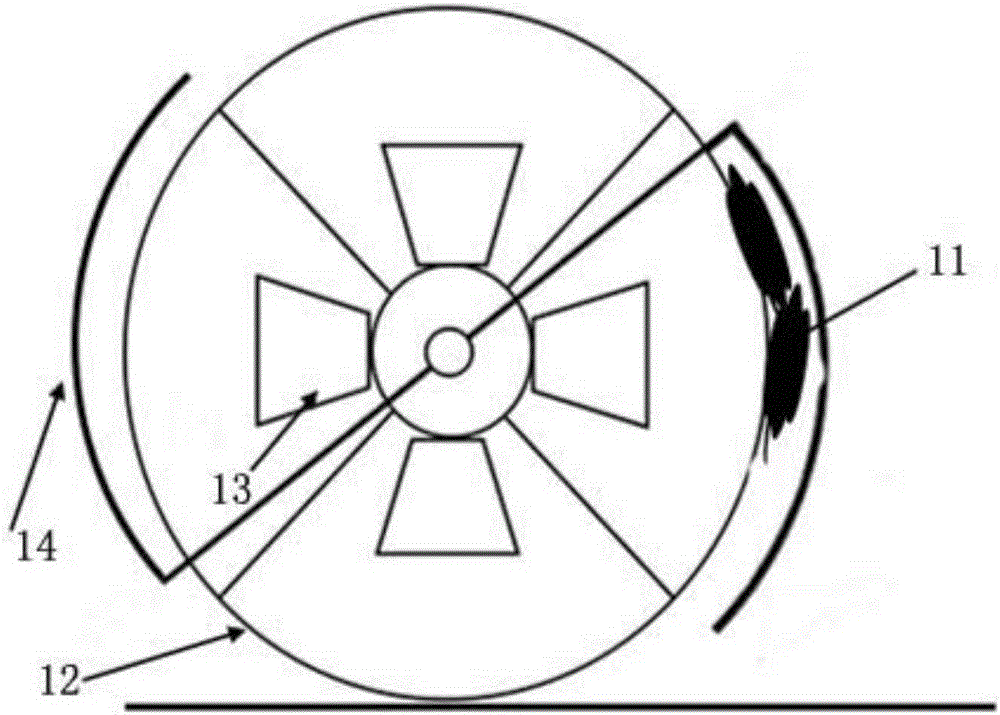

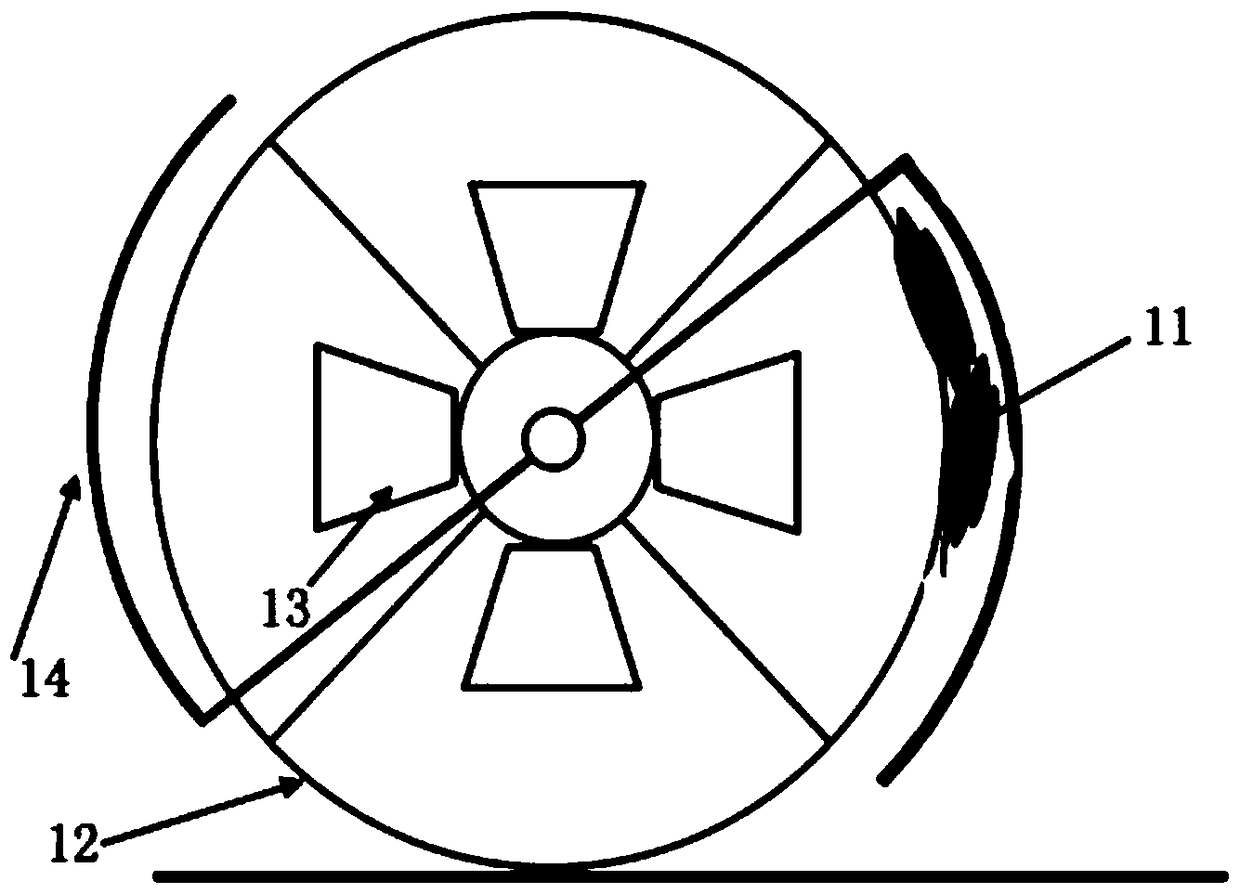

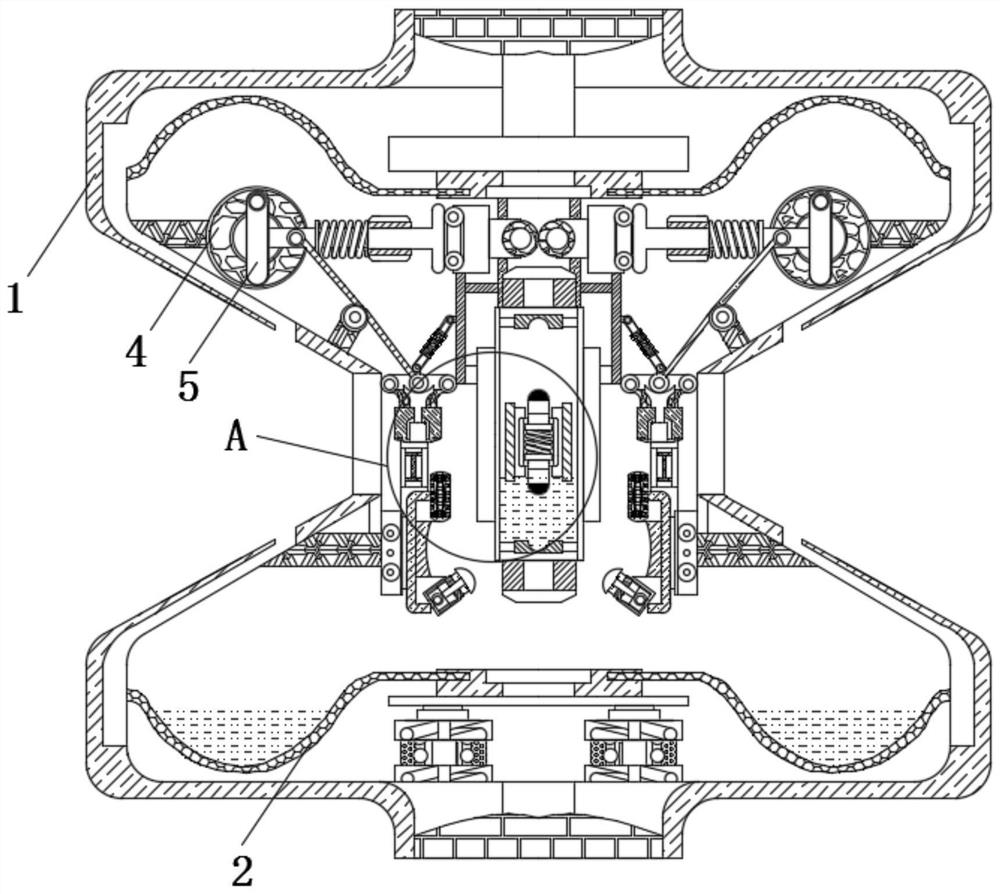

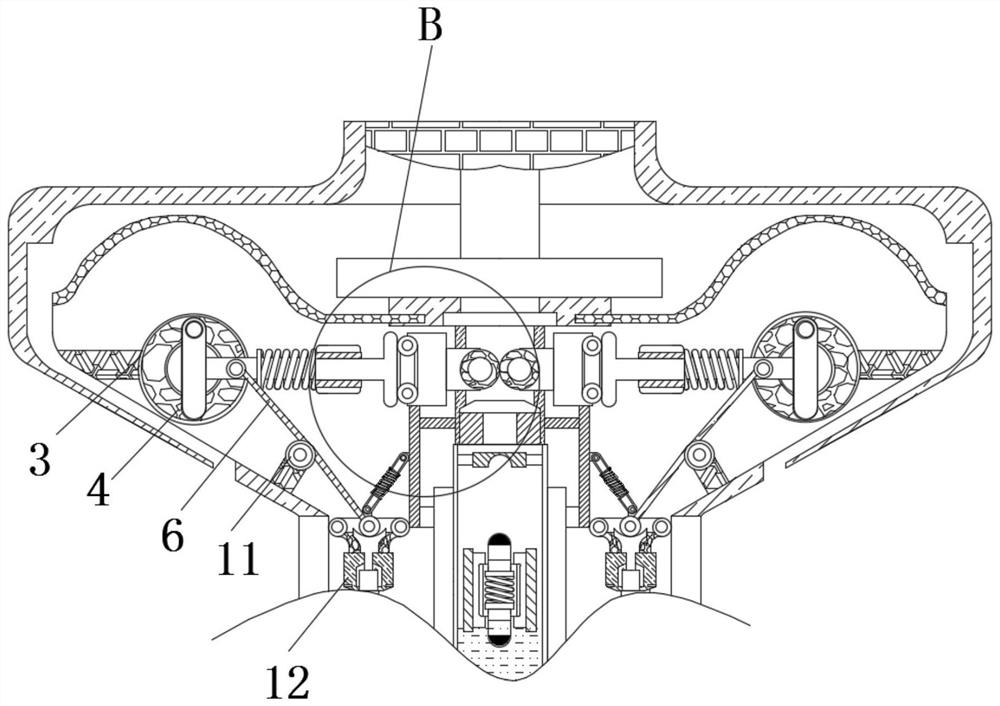

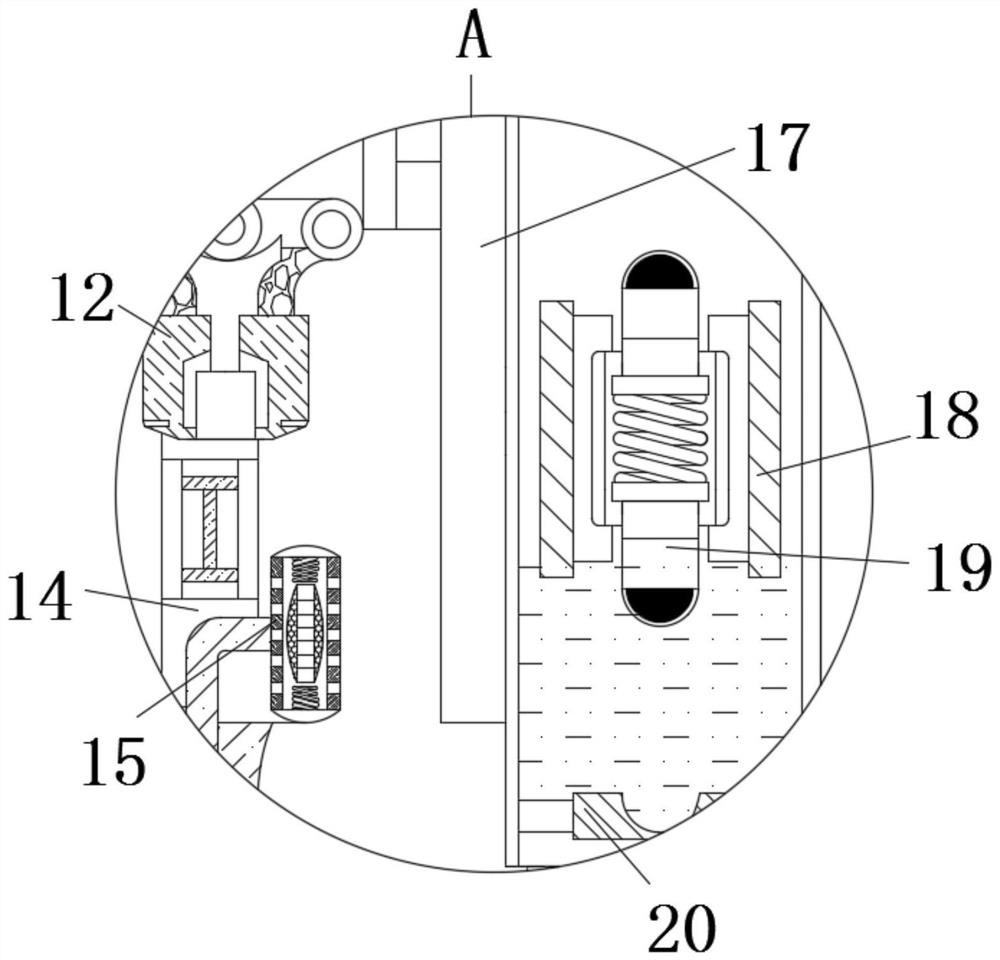

Noise reduction type oil-gas separation device for hydraulic retarder

InactiveCN113898682APrevent leakageNot pollutedLiquid resistance brakesThermodynamicsMachine building

The invention belongs to mechanical manufacturing equipment, and particularly relates to a noise reduction type oil-gas separation device for a hydraulic retarder. An oil-gas separation lower cover of an oil-gas separation assembly in the noise reduction type oil-gas separation device for the hydraulic retarder is arranged on a boss in an inner cavity of a middle cover through an umbrella edge, an oil-gas separation body of the oil-gas separation assembly is installed on the upper end face of the oil-gas separation lower cover in a pressing mode, a dust cover assembly is installed above the middle cover, a metal hole sleeve is arranged in a connecting hole in a dust cover of the dust cover assembly in an inserted mode, a plurality of air inlet and outlet holes are evenly distributed in the outer circumference of the dust cover, a partition plate and a partition plate support are integrated, an oil return cavity is formed between the partition plate and an oil return groove, an air inlet and outlet cavity is formed between the partition plate and the dust cover, the lower end face of the partition plate support is arranged on the lower end face of the oil return groove of the oil-gas separation body in a pressed mode to be axially fixed, a vent hole communicates with the air inlet and outlet cavity and the oil return cavity respectively, and the air inlet and outlet holes in the dust cover communicate with the air inlet and outlet cavity respectively. The structure is simple, oil leakage and loss can be prevented when the working cavity exhausts air, and air can be exhausted thoroughly.

Owner:FUXIN DARE AUTOMOTIVE PARTS

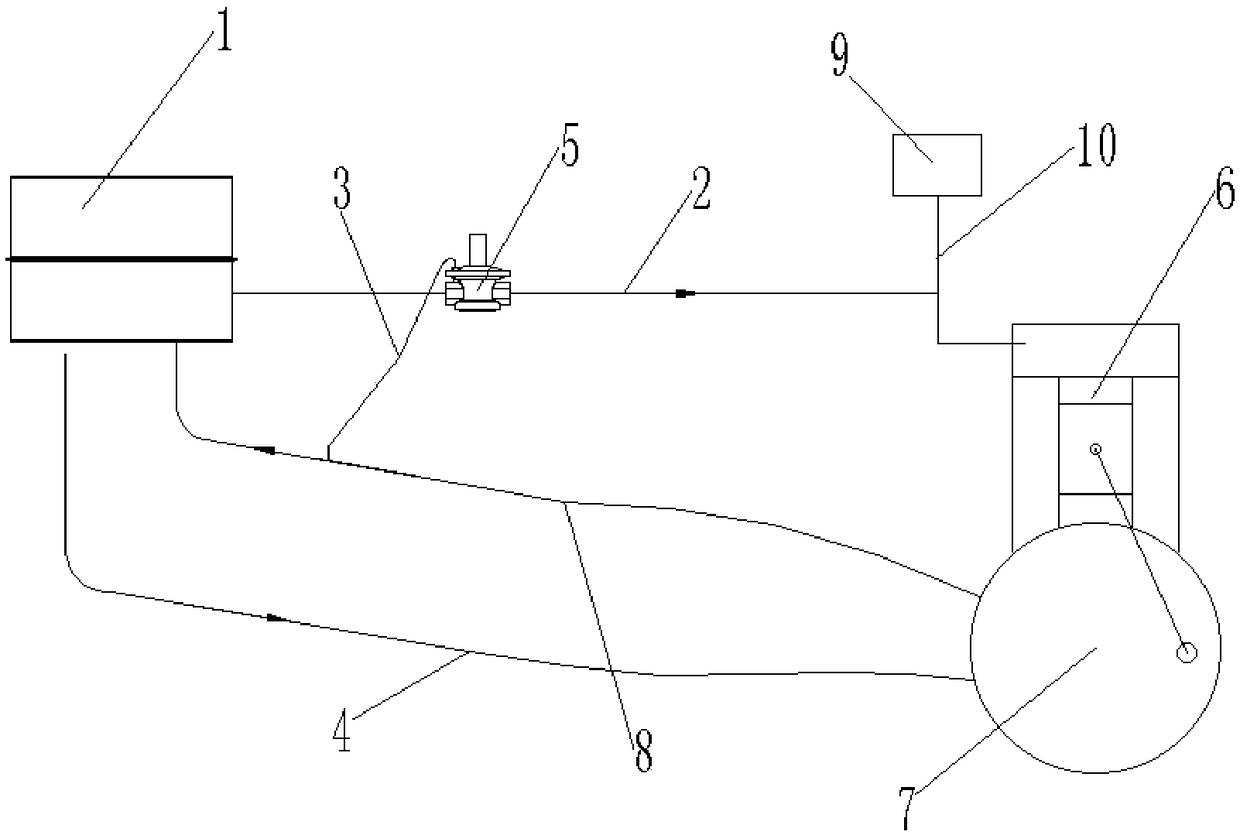

Crankcase ventilation system and gas engine

PendingCN108757098AReduce pollutionGuaranteed normal oil volumeMachines/enginesCrankcase ventillationMembrane configurationFuel gas

The invention provides a crankcase ventilation system and a gas engine and relates to the technical field of oil gas treatment of crankcases of gas engines. The crankcase ventilation system comprisesan oil gas separator, a gas return pipe, a balancing pipe, an oil return pipe, a pressure adjusting valve, an internal-combustion engine, a crankcase and a ventilation pipe, wherein the crankcase communicates to the oil gas separator through the ventilation pipe and an oil and gas mixture can be introduced into the oil gas separator; an oil gas separator box communicates to the crankcase through the oil return pipe, and separated oil can be introduced into the oil gas separator; the oil gas separator box communicates to the internal-combustion engine through the gas return pipe, and separatedmixed gas can be introduced into the internal-combustion engine; the pressure regulating valve is connected to the gas return pipe in series, the crankcase communicates to an upper cavity of a membrane of the pressure regulating valve through the balancing pipe, and the flow of the mixed gas introduced into the crankcase through the gas return pipe can be adjusted. The system alleviates the technical problems that the crankcase ventilation system in the prior art is large in oil consumption, emission is deteriorated, and the pressure of the crankcase cannot be controlled effectively while filtering the gas.

Owner:湖南省力宇燃气动力有限公司

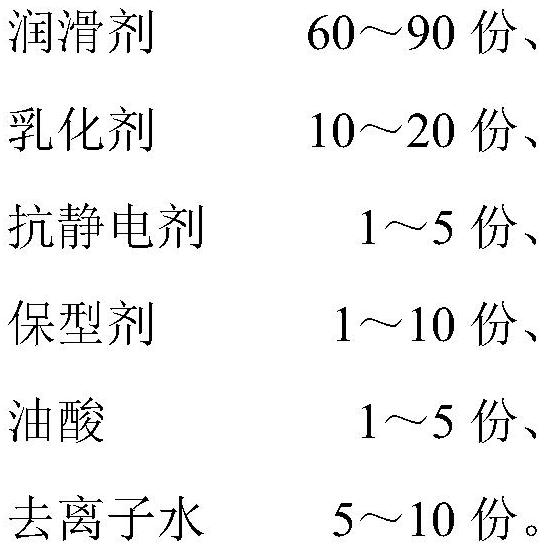

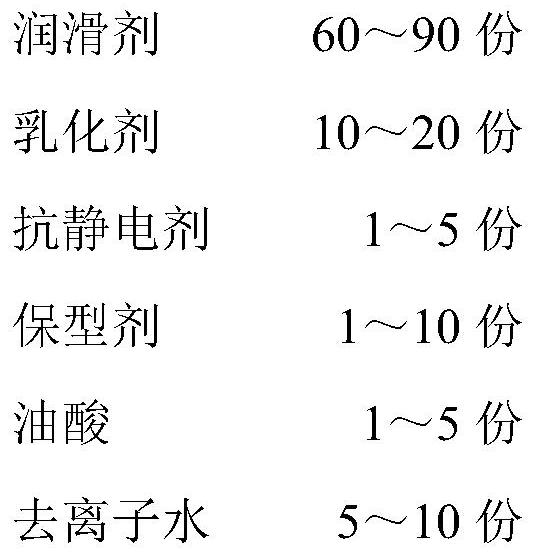

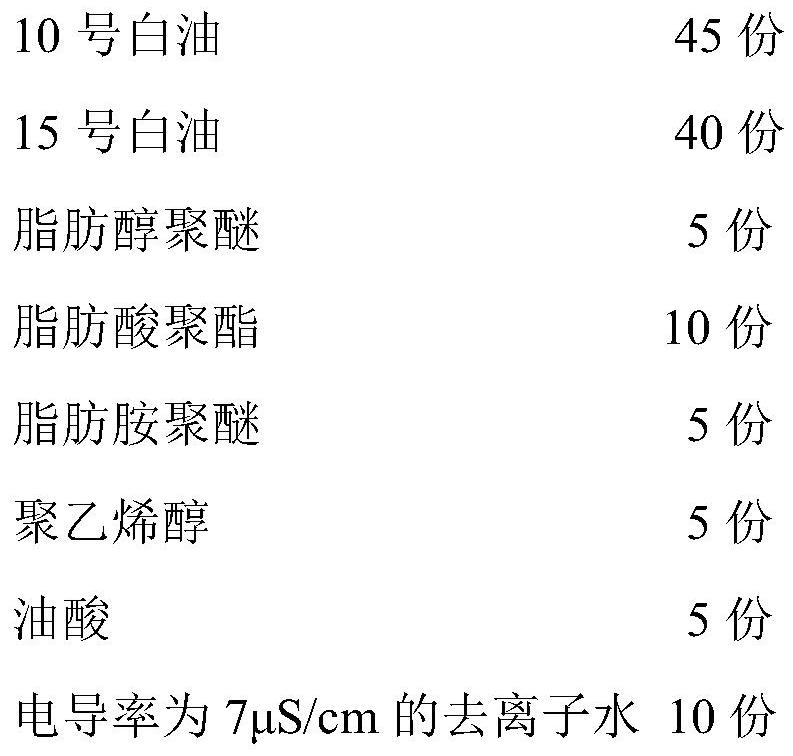

Oiling agent for semi-continuous spinning of viscose filament yarn as well as preparation method and application of oiling agent

PendingCN114351450AStable water-in-oil systemAppearance is clear and transparentCellulose/protein filament chemical after-treatmentVegetal fibresPolymer scienceSpinning

The invention discloses an oiling agent for semi-continuous spinning of viscose filaments as well as a preparation method and application of the oiling agent. The oiling agent is prepared from the following components in parts by mass: 60-90 parts of a lubricant, 10-20 parts of an emulsifier, 1-5 parts of an antistatic agent, 1-10 parts of a shape retention agent, 1-5 parts of oleic acid and 5-10 parts of deionized water. The oil agent prepared by the invention can form a stable emulsion with water, so that a spinning cake can be stiff and elastic and has proper shape retention, the dry strength and dry stretching deviation of inner and outer layer fibers of the spinning cake is smaller, and the edge collapse is less when the spinning cake is wound into a barrel, thereby reducing the end breakage rate of the spinning cake and improving the quality of the fibers.

Owner:SHENYANG HAOBO IND CO LTD

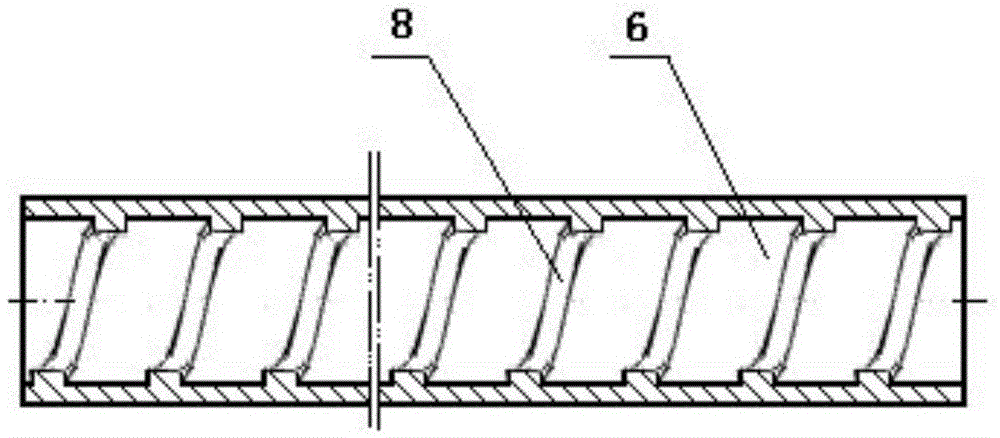

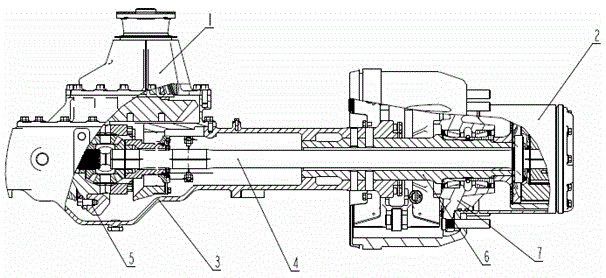

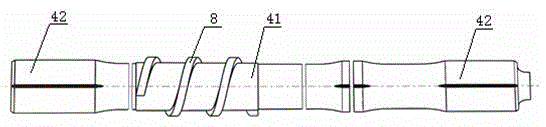

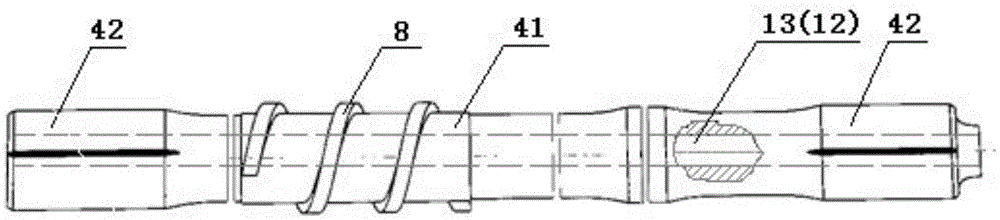

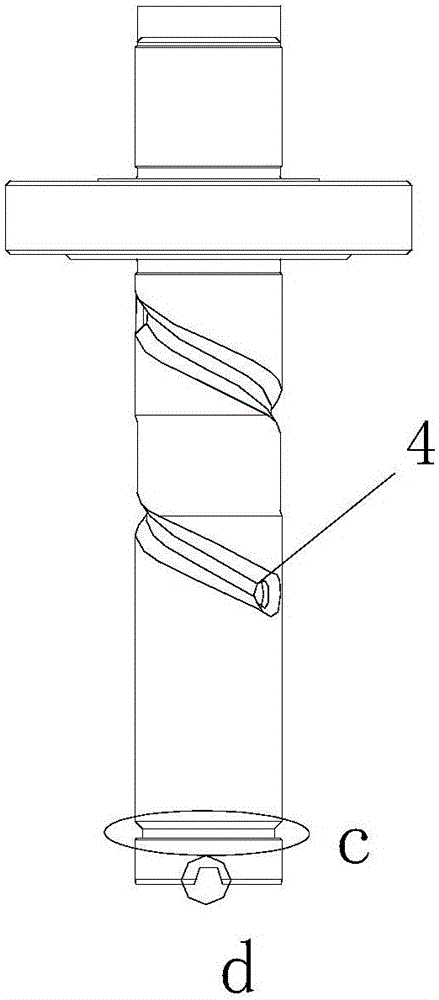

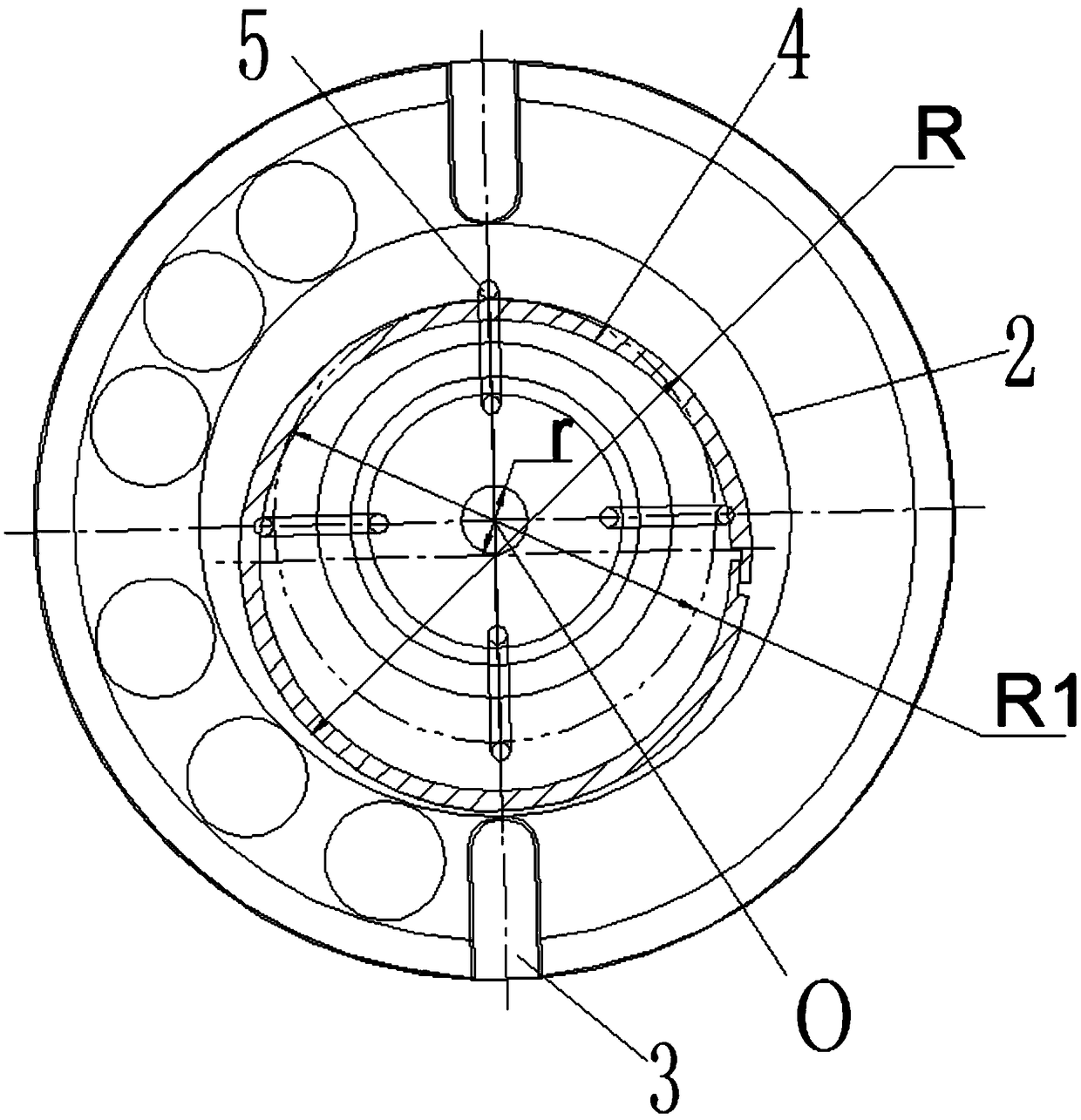

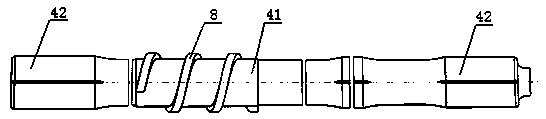

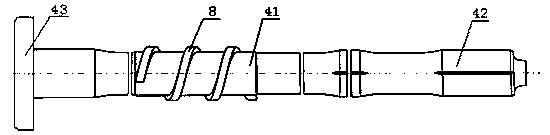

Axle shaft for automobile drive axle

ActiveCN105667212AStable oil quantityGuaranteed oil quantityShaftsGear lubrication/coolingReduction driveCooling effect

The invention discloses an axle shaft for an automobile drive axle, and belongs to the axle shaft for the automobile drive axle of an oil lubricating structure. The axle shaft comprises a shaft body (41) and key connecting parts located at the two ends of the shaft body (41), or, the axle shaft comprises the shaft body (41), a key connecting part located at one end of the shaft body (41) and a flange (43) located at the other end of the shaft body (41). A spiral structure (8) is arranged on the outer surface of the shaft body (41), and when the shaft body (41) rotates for driving a wheel hub (7) and an automobile to move forwards, the direction of conveying lubricating liquid with the spiral structure (8) is pointed to one side of a main speed reducer (1). The axle shaft for the automobile drive axle is simple in structure, novel in design, easy and convenient to manufacture and capable of keeping the oil amount of each cavity stable, guarantees that all components are lubricated thoroughly, especially has good oil gas exhausting and cooling effects on a wheel end mechanism (2), effectively prolongs the service life of a drive axle system, and is applicable to all automobile drive axles adopting oil lubrication.

Owner:DONGFENG COMML VEHICLE CO LTD

Half axle for vehicle

ActiveCN105599540AStable oil quantityGuaranteed oil quantityShaftsAxle unitsReduction driveCooling effect

The invention discloses a half axle for a vehicle. The half axle comprises an axle body (41) and key connection portions (42) located at the two ends of the axle body (41). An axle inner channel (12) is arranged below the outer surface of the axle body (41). The outer surface or the axle inner channel (12) of the axle body (41) is provided with a spiral structure. When the axle body (41) rotates to drive a hub (7) or a vehicle to move forwards, the spiral structure (8) outputs lubricating liquid towards one side of a main speed reducer (1); or the outer surface and the axle inner channel (12) of the axle body (41) are each provided with a spiral structure (8), and circular flow of lubricating liquid in a driving axle is propelled. The half axle is simple in structure, novel in design, easy and convenient to manufacture, capable of ensuring stability of the oil quantity in each cavity and ensuring that the all the components are sufficiently lubricated, particularly good in oil gas exhaust effect and cooling effect on a wheel end mechanism (2) and applicable to all driving axles with wheel end mechanisms adopting lubricating oil, and the service life of a driving axle system is effectively prolonged.

Owner:DONGFENG COMML VEHICLE CO LTD

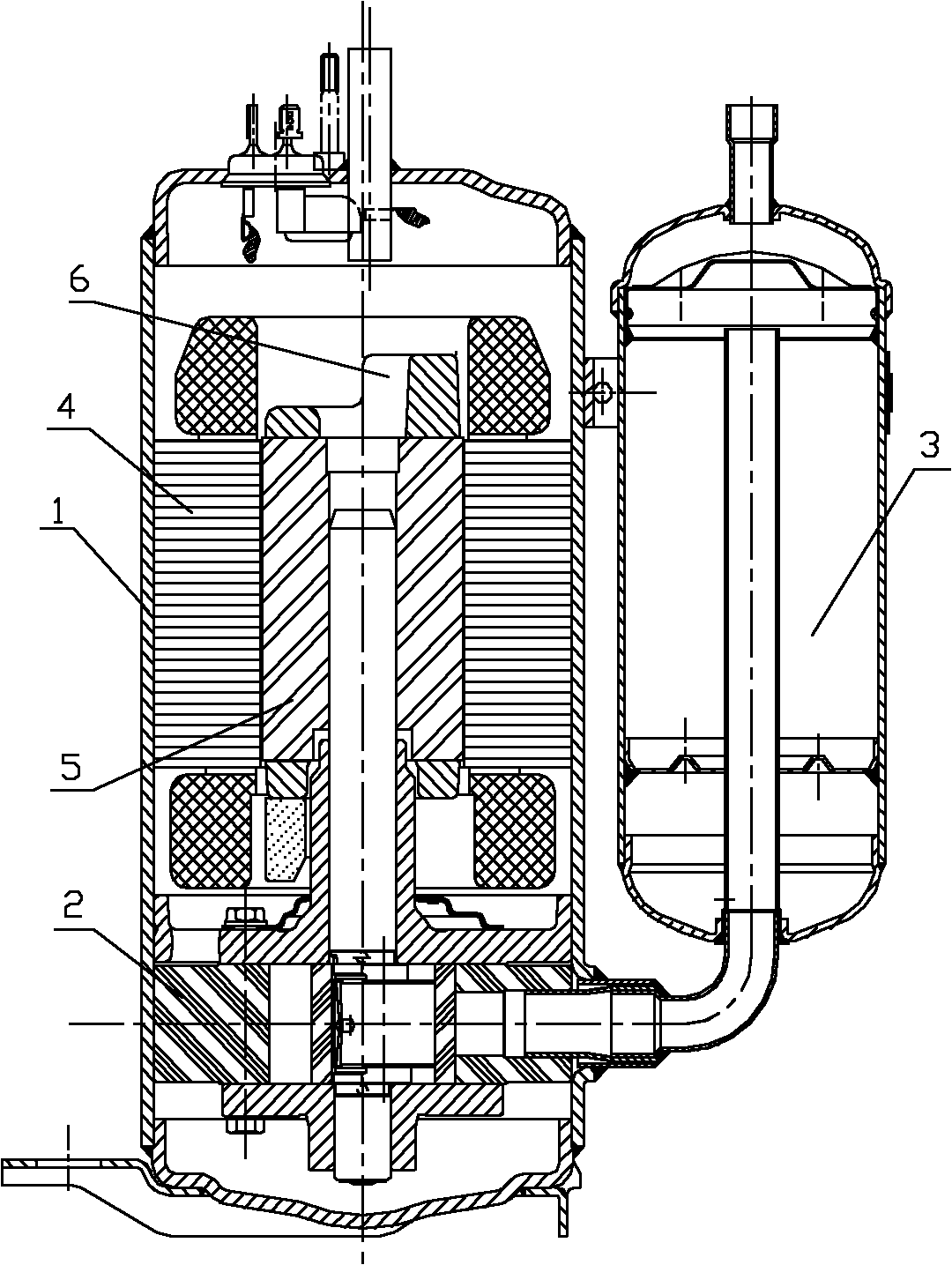

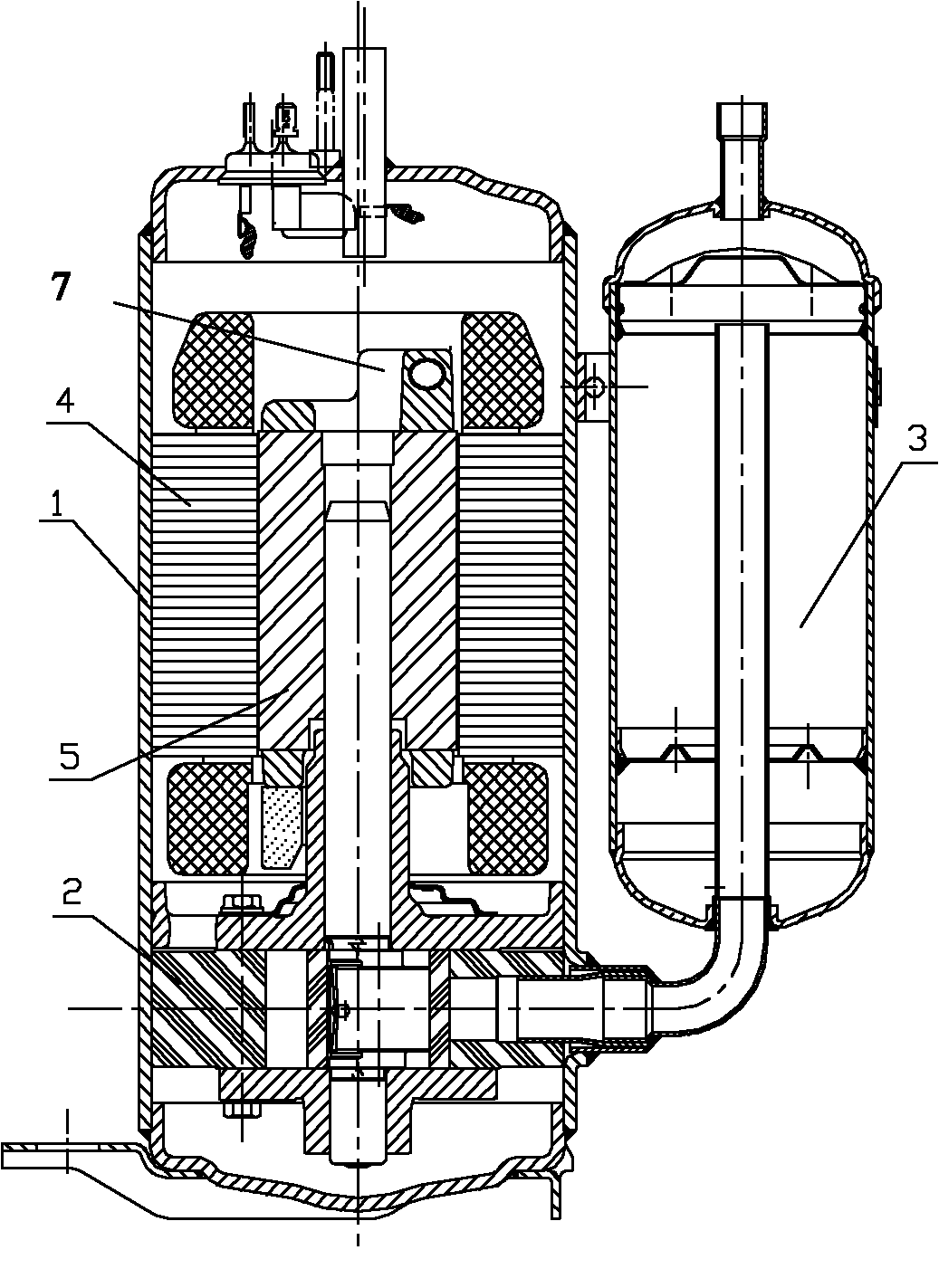

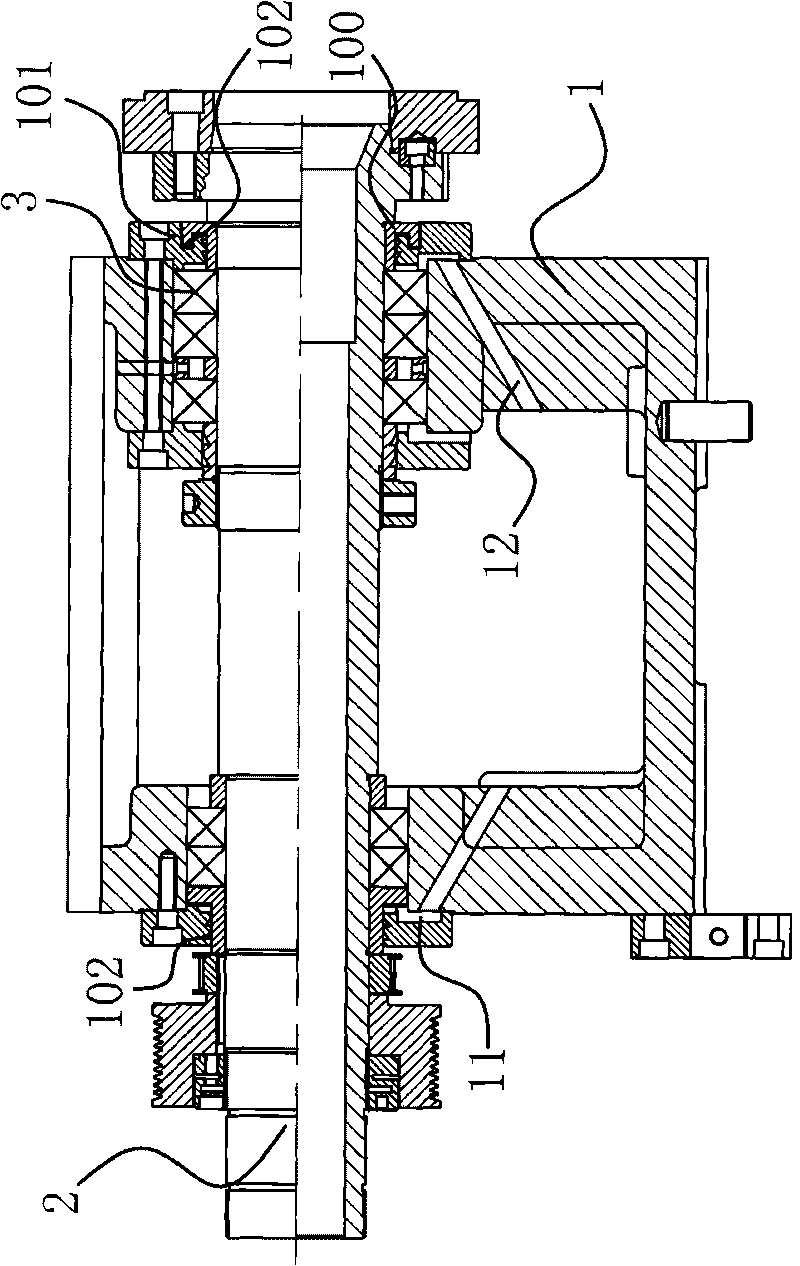

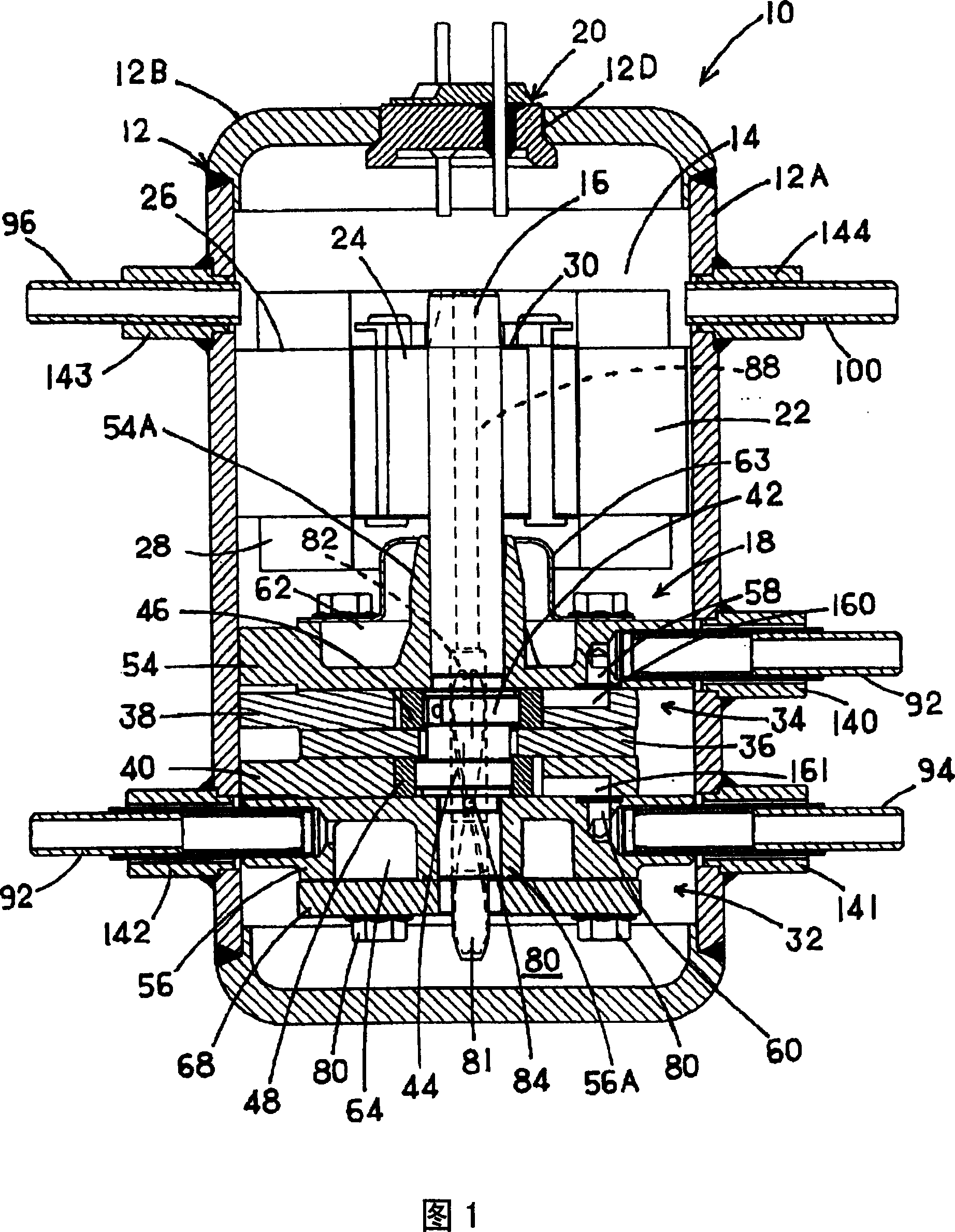

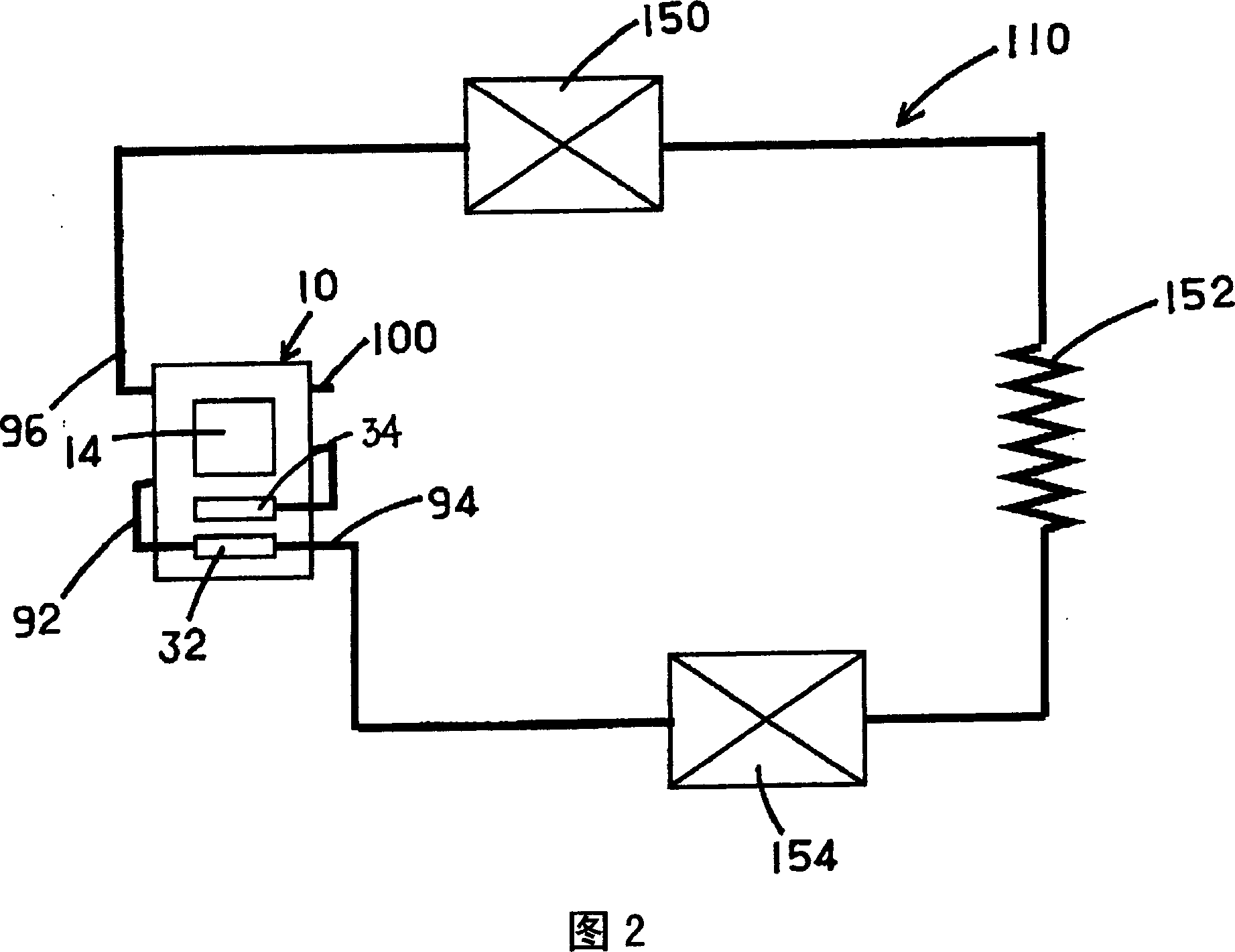

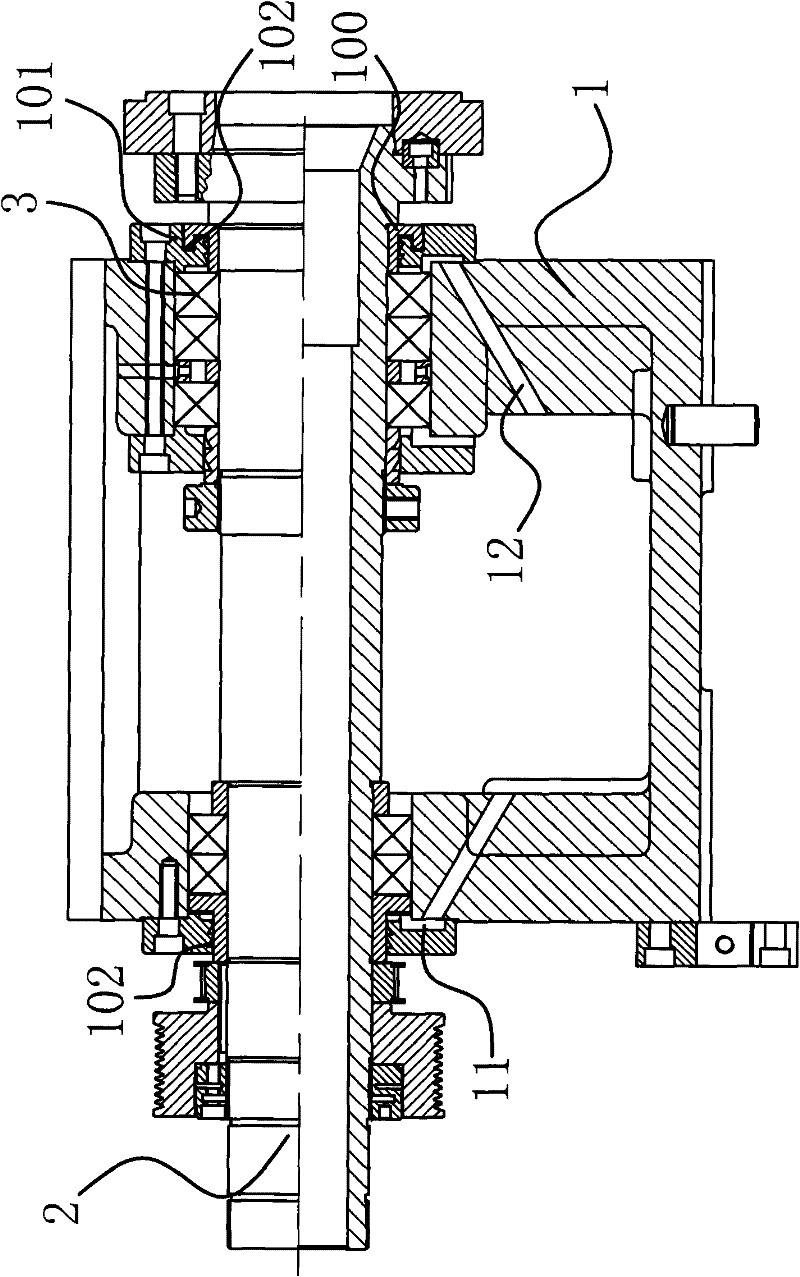

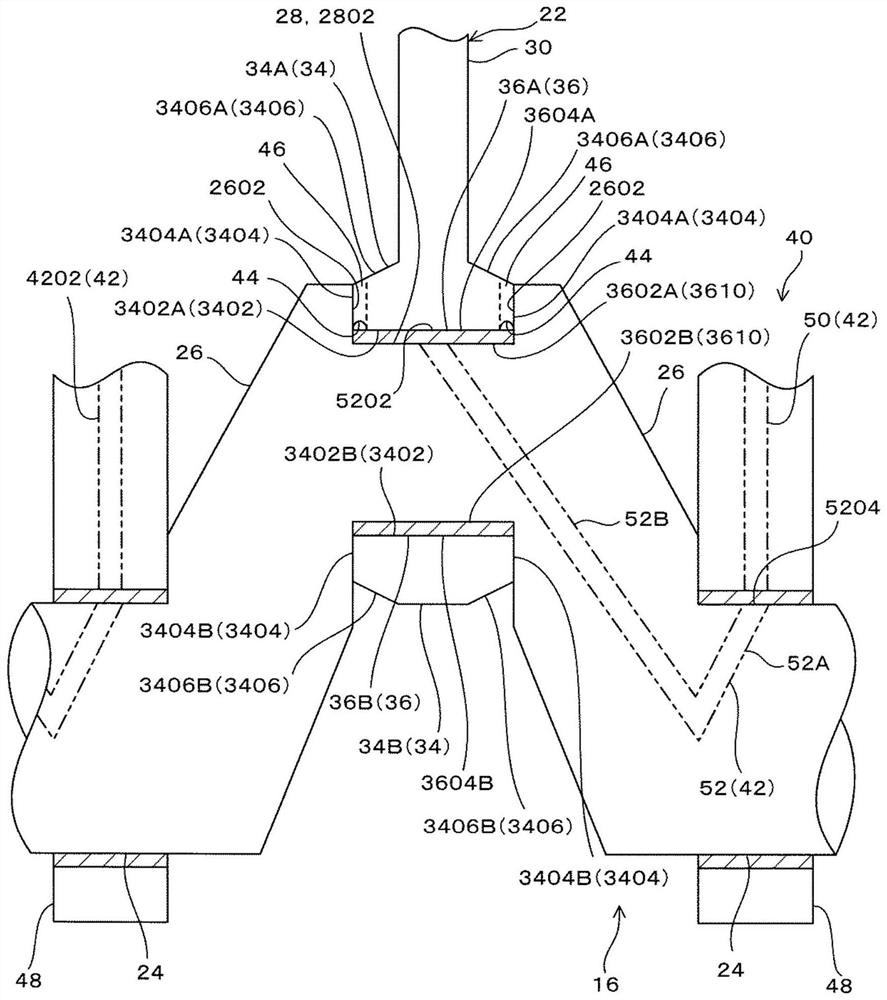

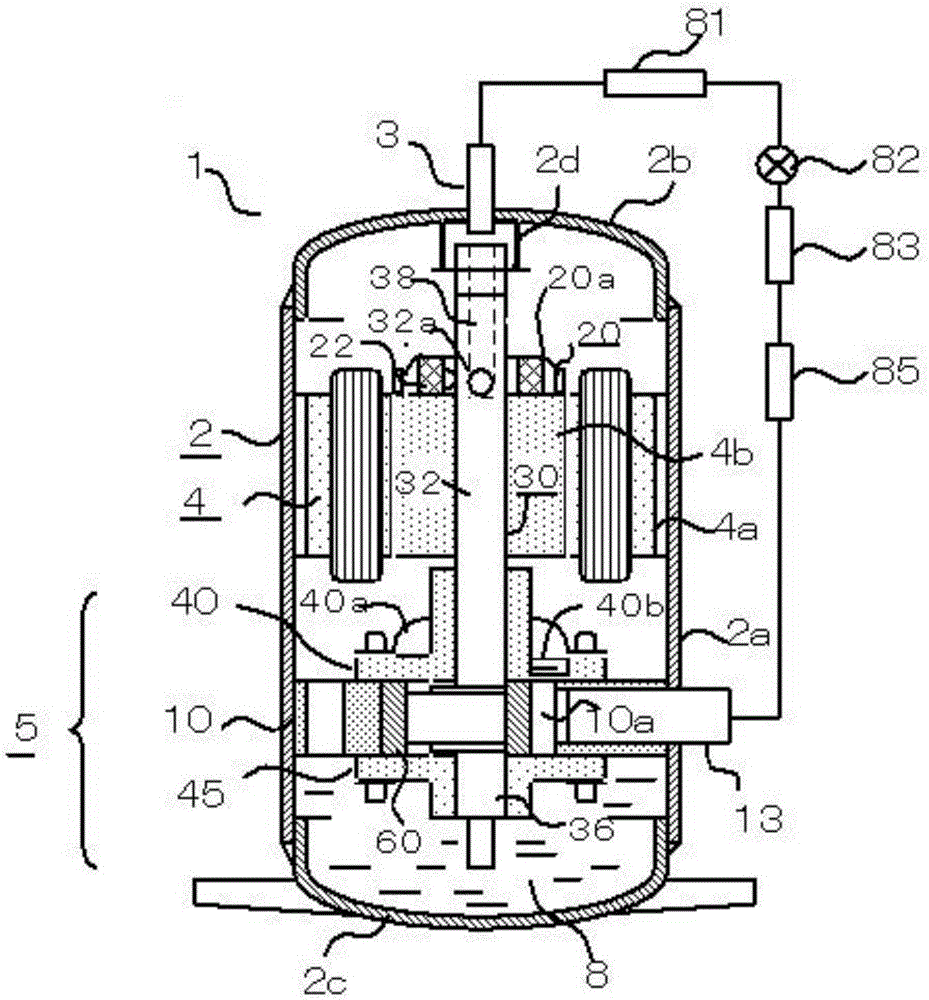

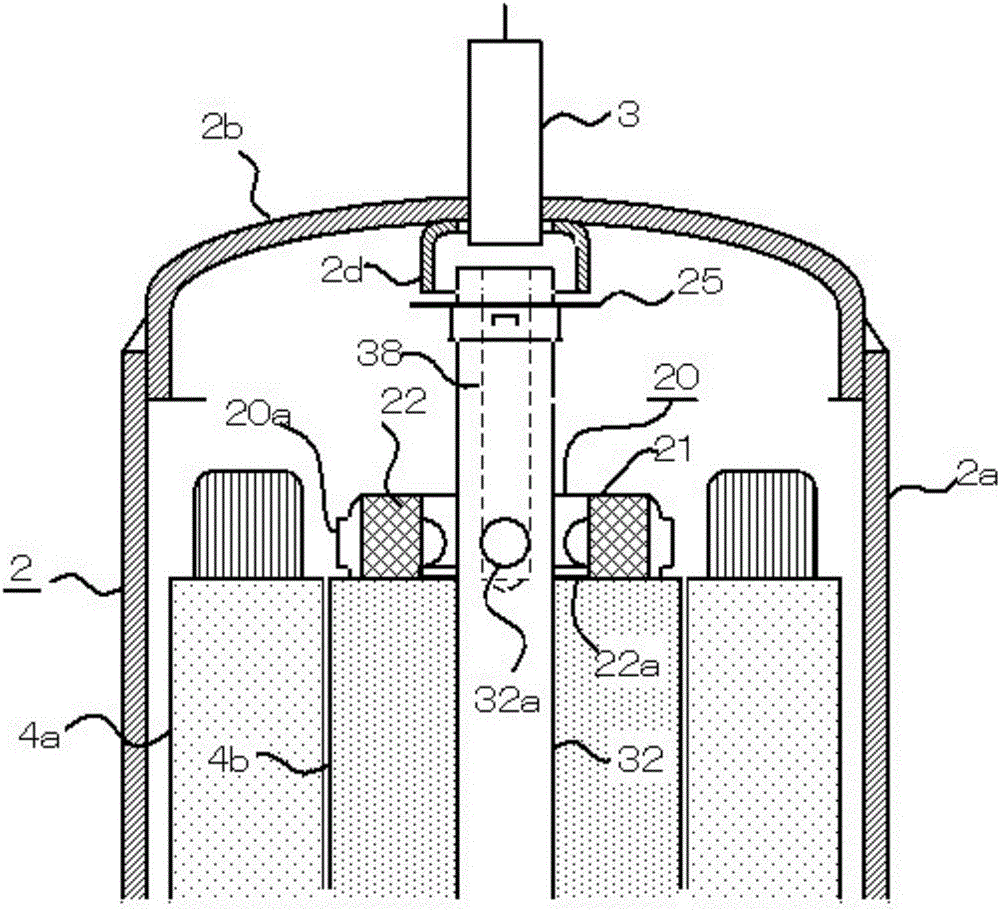

Refrigerant compressor and refrigerant cycle device including the same

InactiveCN1940295AGuaranteed oil quantityImprove sealingCompressorPositive displacement pump componentsEngineeringAir compressor

An object is to provide a refrigerant compressor which solves a disadvantage that an oil flows into a refrigerant circuit in the outside of the refrigerant compressor during introduction of the oil and which minimizes an amount of the oil to be introduced and which can secure a sufficient amount of the oil, and a refrigerant cycle device including the refrigerant compressor. A rotary compressor (refrigerant compressor) comprises, in a sealed container (12), an electromotive element (14) as a driving element, and a rotary compression mechanism part (18) driven by this electromotive element (14) and constituted of first and second rotary compression elements (32,34), and discharges a refrigerant compressed by the rotary compression mechanism part (18) from the sealed container, the compressor further comprising an oil reservoir (80) constituted in a bottom part of the sealed container; and a servicing pipe (100) attached to the sealed container to introduce the refrigerant and the oil into the sealed container.

Owner:SANYO ELECTRIC CO LTD

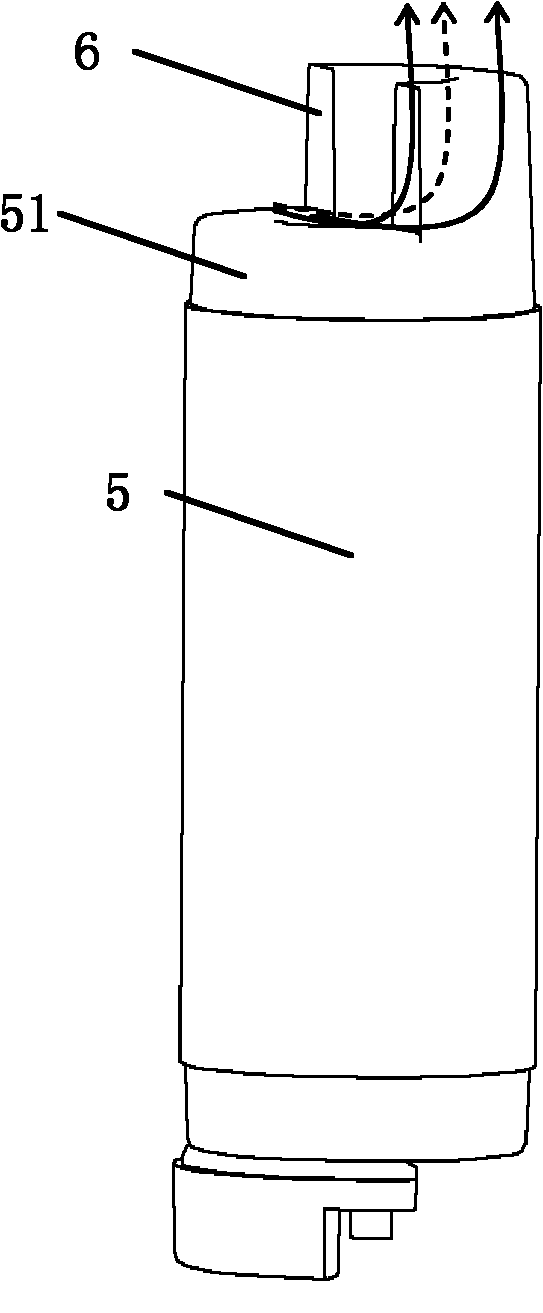

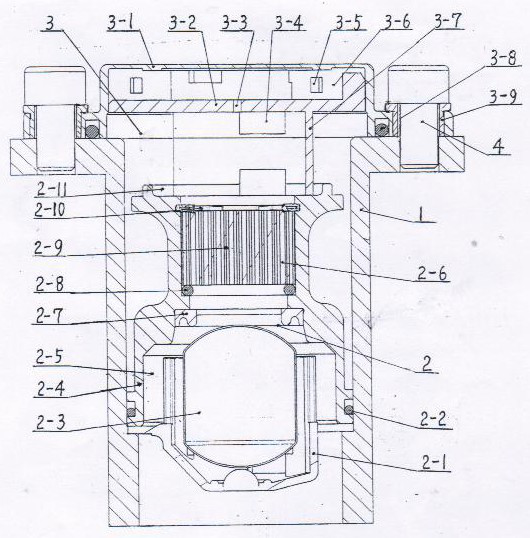

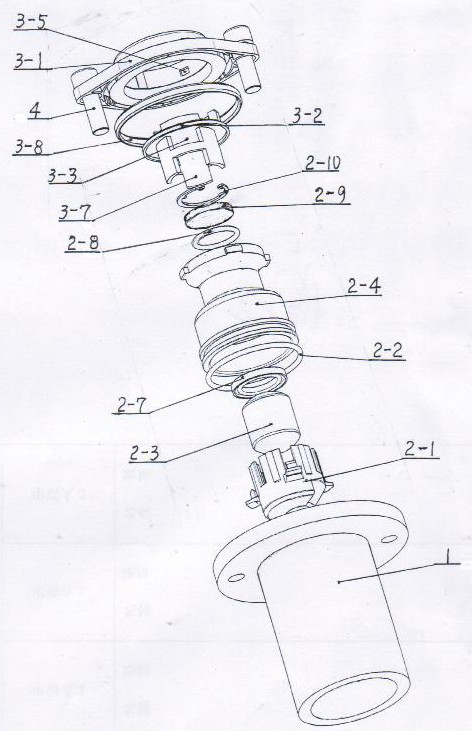

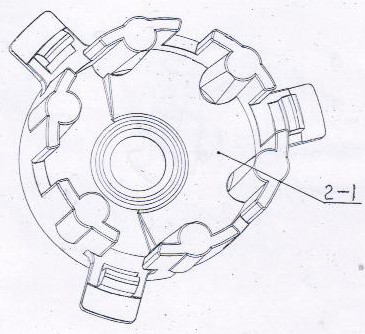

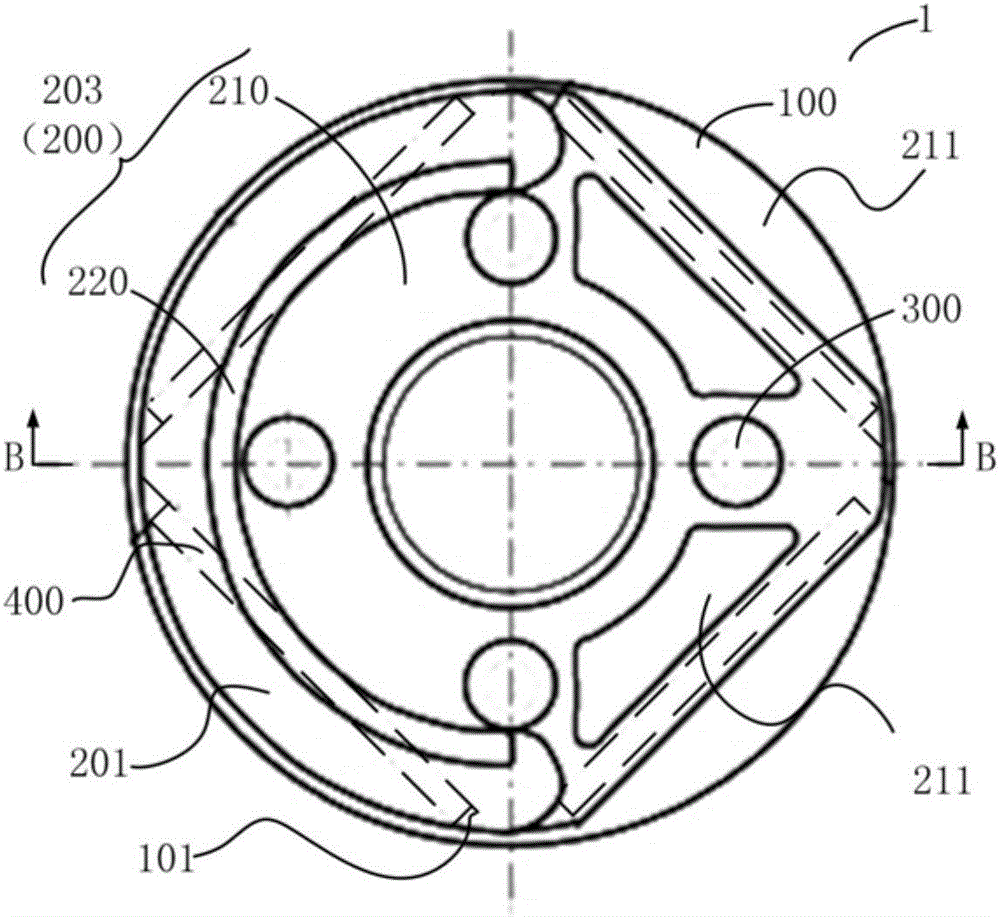

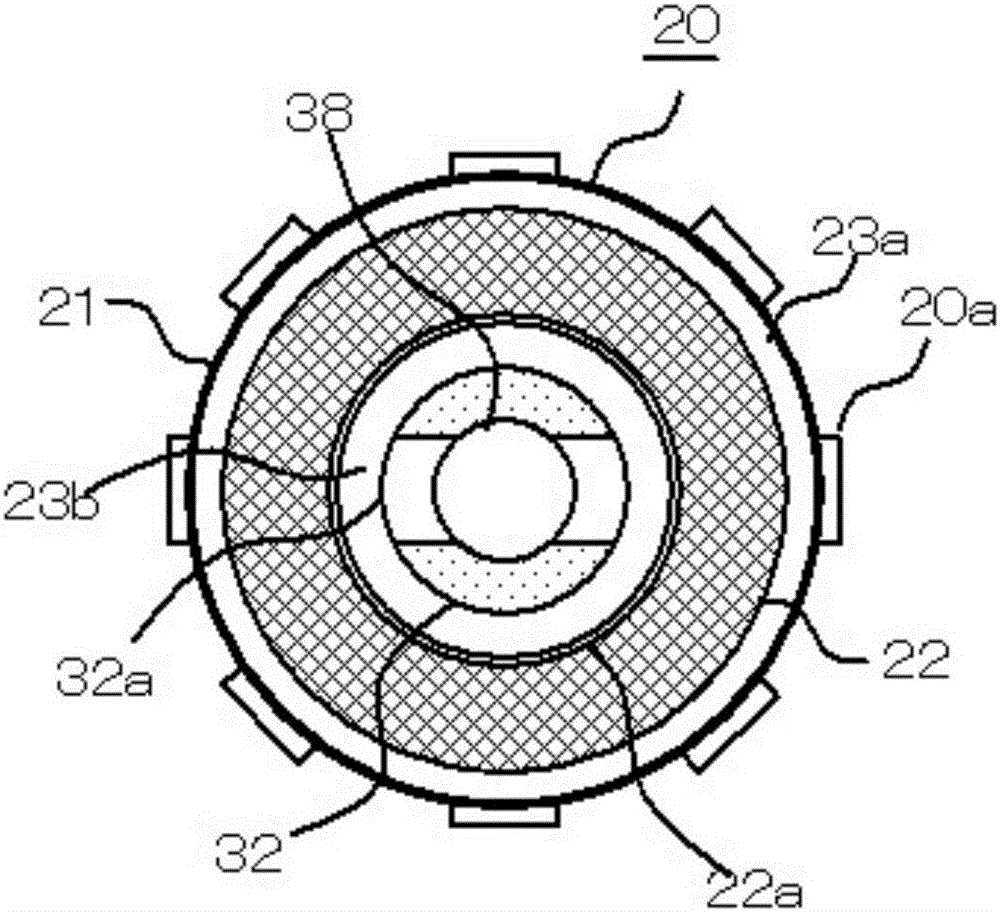

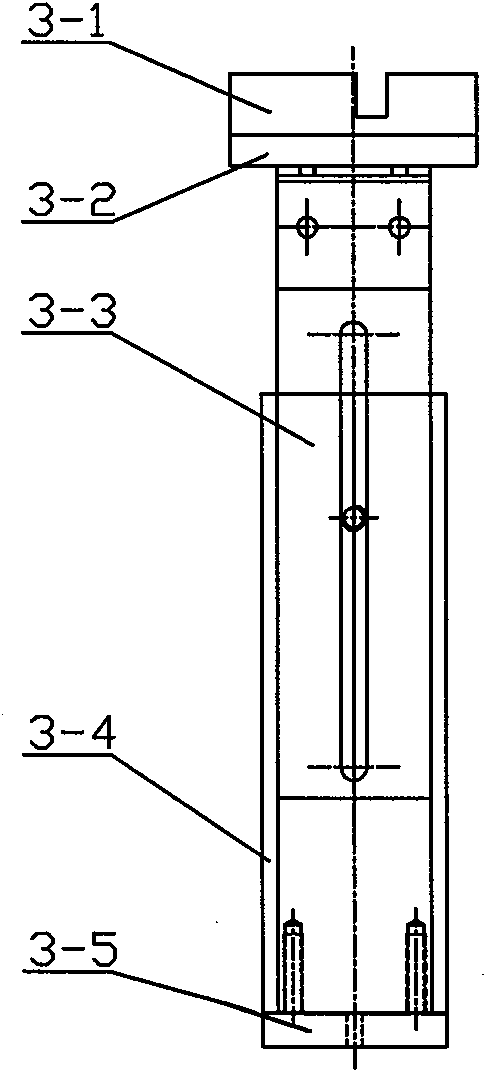

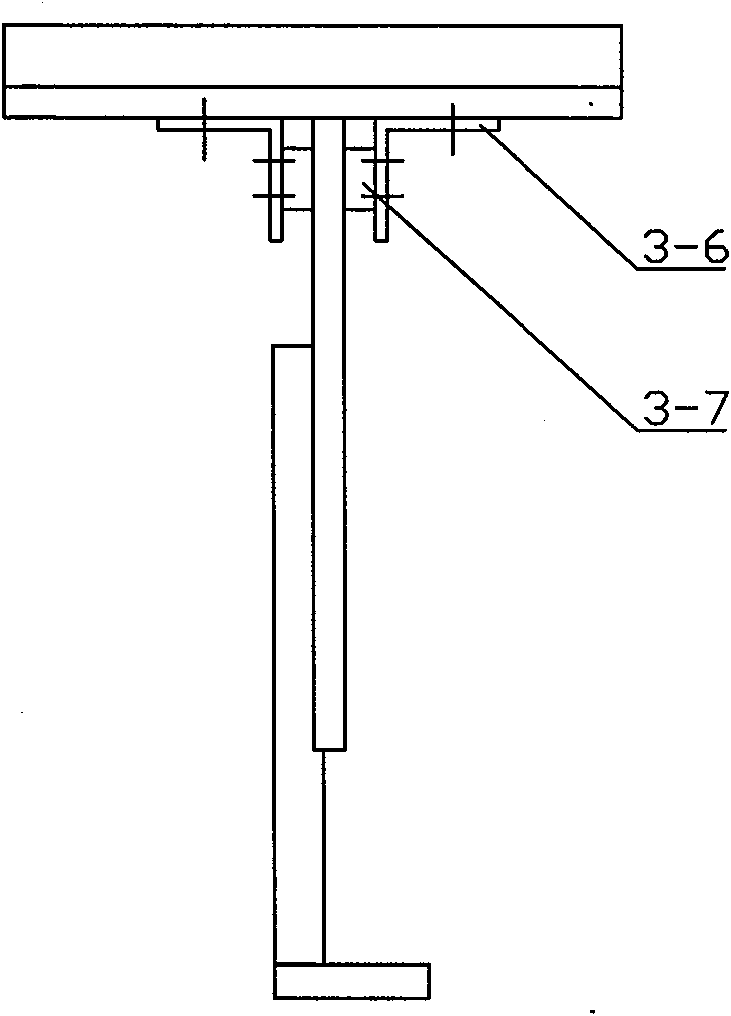

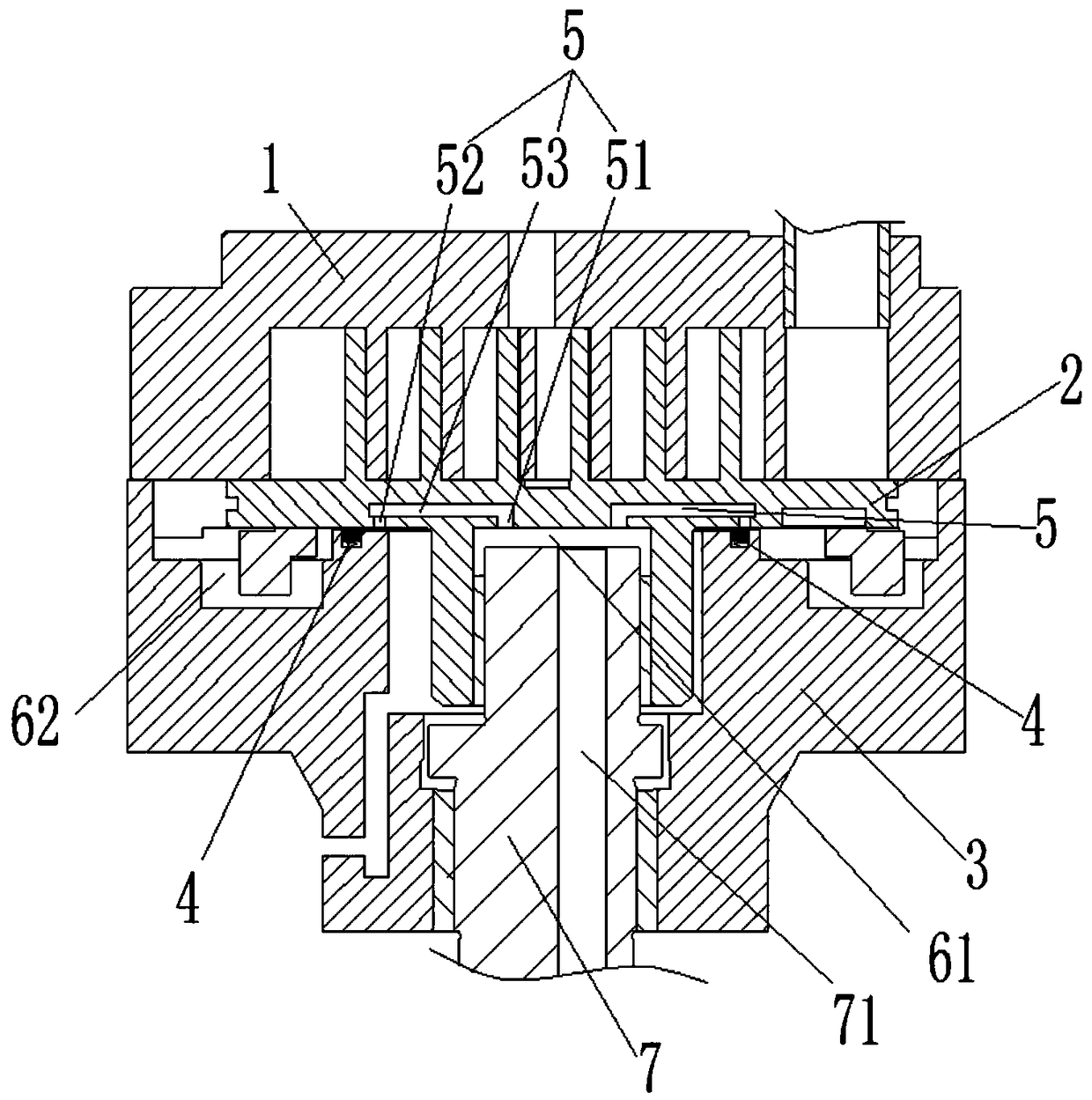

Motor rotor for compressor, motor for compressor, and compressor

InactiveCN106130248AGuaranteed oil quantityInhibit stirringRotary/oscillating piston combinations for elastic fluidsMagnetic circuit rotating partsEngineeringMechanical engineering

The invention discloses a motor rotor for a compressor, a motor for the compressor, and the compressor. The motor rotor for the compressor comprises a rotor iron core and at least one balance block, wherein the rotor iron core is provided with a compression end and a decompression end in an axial direction; the balance block comprises a mounting part and a balance part; the mounting part is mounted on at least one end plane of the compression end and the decompression end of the rotor iron core; the balance part is connected with the surface, opposite to the end plane, of the mounting part, and can extend in the circumference direction of the rotor iron core; and an inclined plane which is tilted relative to the end plane is arranged between the outer end plane and the outer circumferential surface of the balance part. According to the motor rotor for the compressor provided by the invention, the motor rotor is particularly applicable to high-rotary-speed operation; under a condition that the motor characteristic of the compressor is ensured, the separation effect of oil and liquid contained in a refrigerant gas can be improved; the oil liquid flowing in a refrigerating and circulating system can be restrained; and the oil amount in the compressor can be ensured.

Owner:GUANGDONG MEIZHI COMPRESSOR

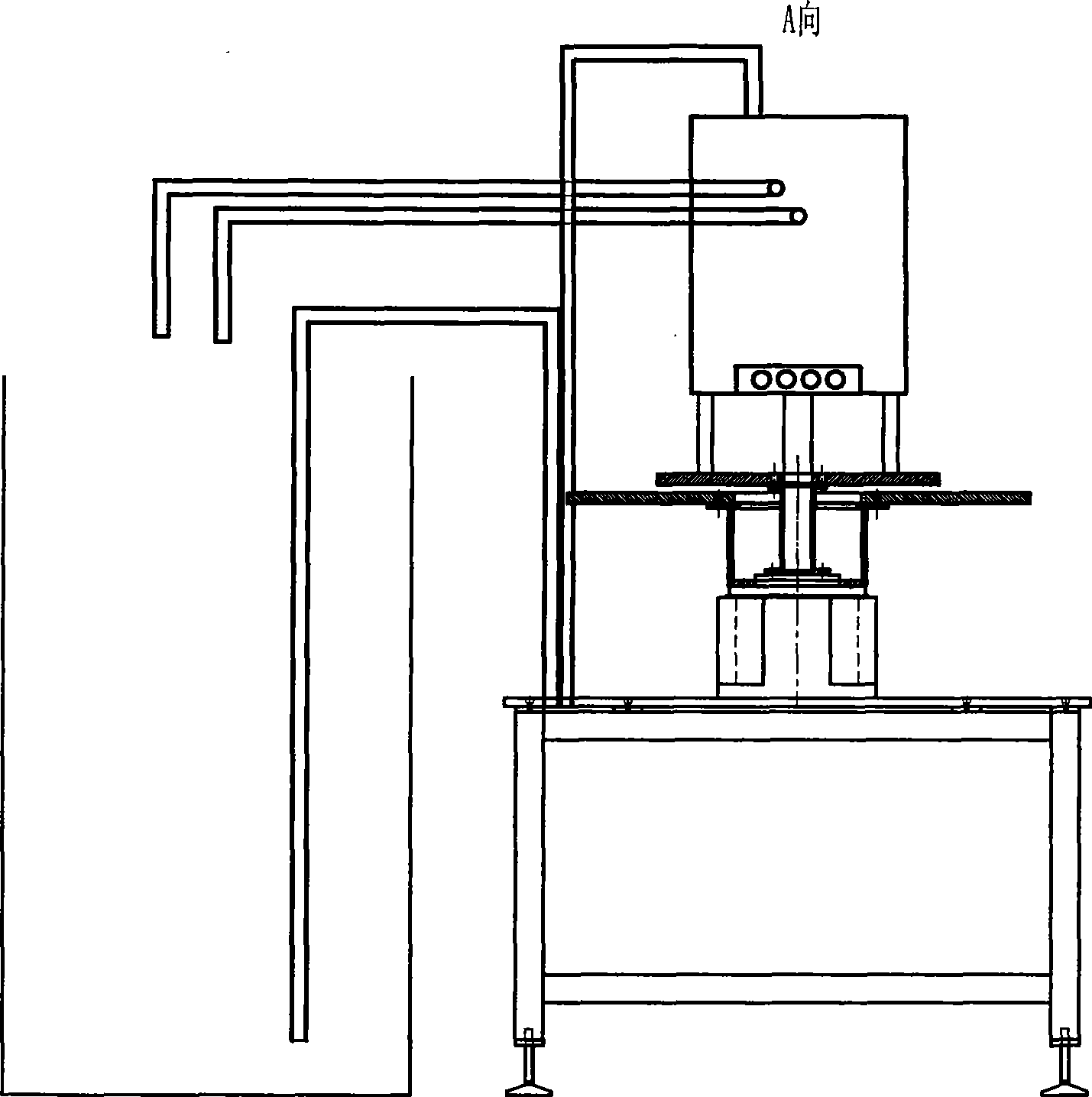

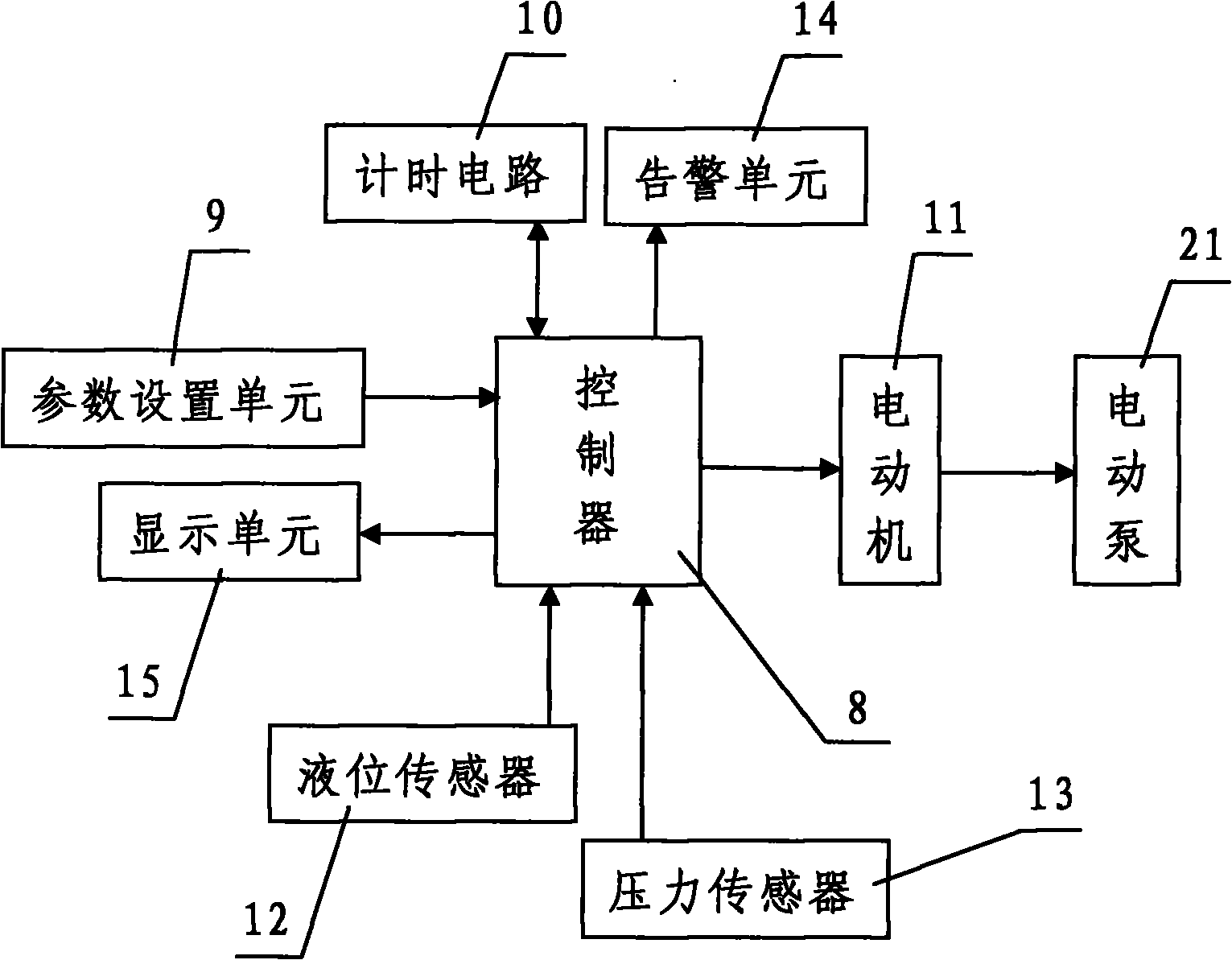

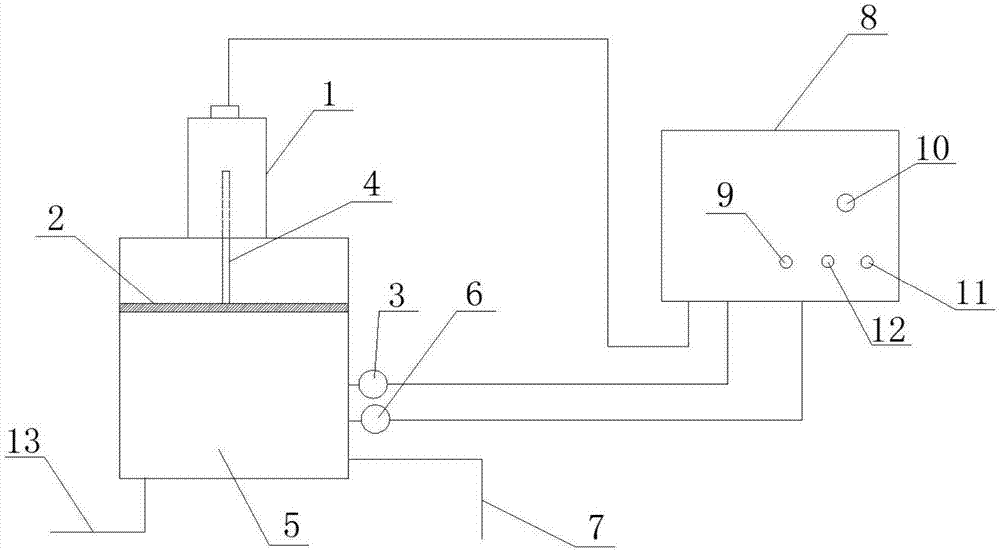

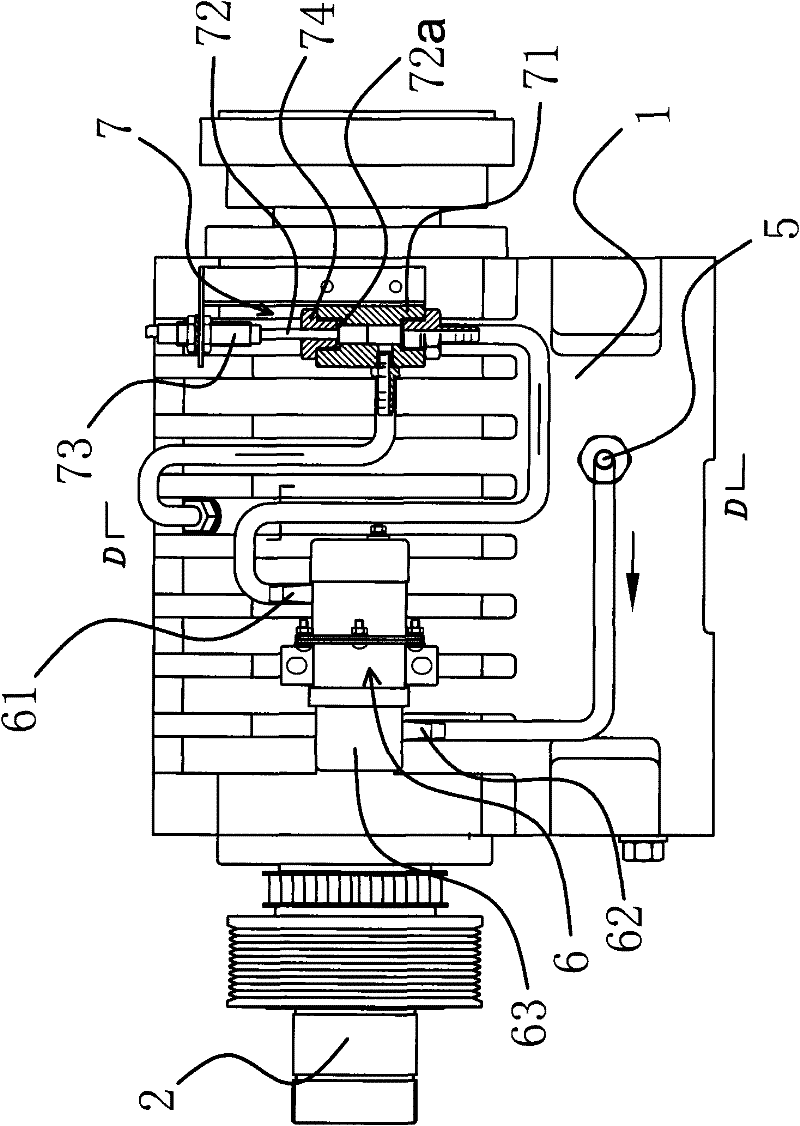

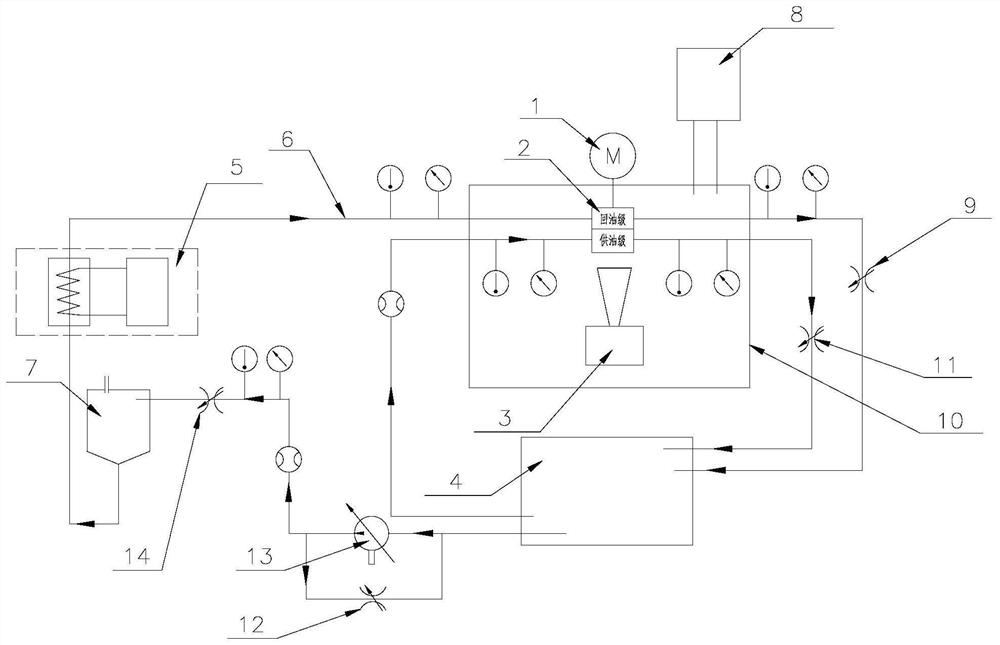

Automatic lubricating system and method of motor of ventilator

PendingCN107448761AReduce labor intensityGuaranteed oil quantityEngine temperatureEngine pressureElectric machineryMotor shaft

The invention discloses an automatic lubricating system and method of a motor of a ventilator. The automatic lubricating system comprises an oil storage tank used for storing lubricating oil, and an oil inlet pipe is connected to the bottom of the oil storage tank; an oil injection pipe is connected to the lower side of the oil storage tank; the outlet end of the oil injection pipe is connected to an oil injection hole of a bearing chamber of the motor of the ventilator; a pressing plate used for pushing lubricating oil downwards is arranged in the oil storage tank; a pushing motor is arranged at the upper part of the oil storage tank; the output end of the pushing motor is connected with a push rod; the free end of the push rod is connected with the pressing plate; and the pushing motor is connected to a controller through a cable. According to the automatic lubricating system, labor intensity of manual oil injection operating personnel of the lubricating system of the motor of the ventilator is reduced, the oil injection quantity of the motor is guaranteed, and fine management of the device is achieved.

Owner:SHAANXI NANLIANG MINING

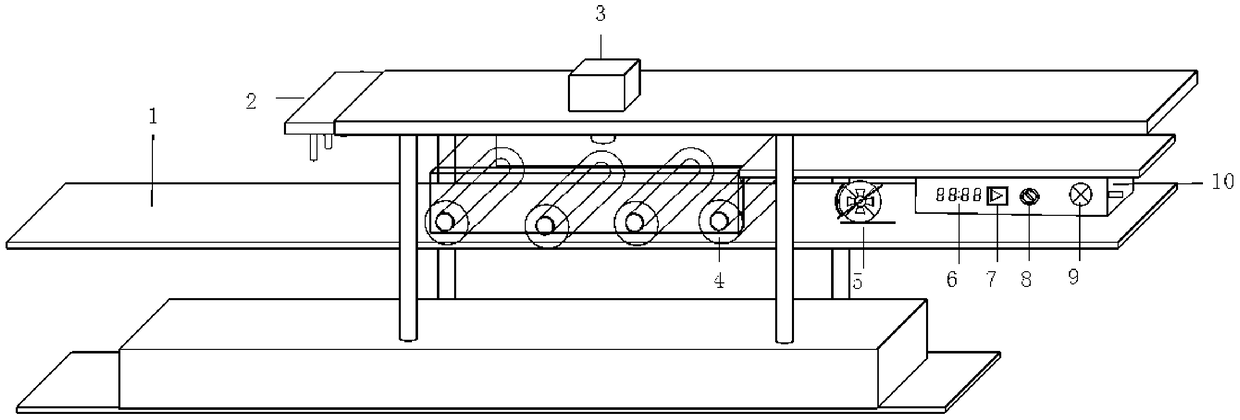

Automatic conveying belt cleaning device

The invention discloses an automatic conveying belt cleaning device which comprises a conveying belt, oil wiping rollers and a cylinder. The cylinder is connected with the oil wiping rollers through a control rod. An oil stain sensor is arranged on the conveying belt. The cylinder and the oil stain sensor are connected with a controller. By means of the oil wiping rollers, damage to the conveying belt can be substantially reduced, and meanwhile, oil stains on the surface layer of the conveying belt are deeply cleaned away. According to the automatic conveying belt cleaning device, full-automatic detection of operation and stopping can be achieved, and the oil wiping rollers are embedded in a movable buckling mode so that the oil wiping rollers can be quickly replaced. Meanwhile, the setting of automatic cleaning is adopted, and routine automatic cleaning is carried out to guarantee that the oil amount on the conveying belt is the lowest in the whole course. The automatic conveying belt cleaning device is a universal type cleaning device and can be widely applied to various production lines for longitudinal cutting, horizontal cutting, blanking and the like, a large quantity of manpower is saved, and potential safety hazards are reduced; the downtime is shortened, the product surface quality is improved, and the production efficiency and the client satisfaction are indirectly improved.

Owner:NANJING BAOSTEEL SUMMIT METAL PRODUCTS CO LTD

Lubricating device of head stock in universal machine tool

InactiveCN101700634BAvoid wastingIncrease profitMaintainance and safety accessoriesDrive shaftEngineering

Owner:玉环时代经典机床有限公司

A fire prevention test device for lubricating oil pump with external circulation of oil and gas

ActiveCN111306053BAchieve normal operationGuaranteed oil quantityFluid parameterPositive-displacement liquid enginesHeating oilCombustor

Owner:HARBIN DONGAN ENGINE GRP

A conveyor belt automatic cleaning device

The invention discloses an automatic conveyor belt cleaning device, which comprises a conveyor belt, an oil rubbing roller and a cylinder, the cylinder is connected with the oil rubbing roller through a control rod, an oil dirt sensor is arranged on the conveyor belt, and the The cylinder and the oil pollution sensor are respectively connected with the controller. The oil rubbing roller adopted by the invention can greatly reduce the damage to the conveyor belt, and at the same time deeply clean the oil stain on the surface of the conveyor belt. The invention can realize full-automatic detection operation and stop, and the oil rubbing roller is embedded in the way of loose buckle, and the replacement operation can be completed quickly. At the same time, the setting of automatic cleaning is adopted to carry out routine automatic cleaning to ensure that the oil quantity of the conveyor belt is at the minimum standard throughout the process. The invention is a general-purpose cleaning device, which can be widely used in various vertical and horizontal cutting, blanking and other production lines, saving a lot of manpower, reducing safety hazards, reducing downtime, improving product surface quality, and indirectly improving production efficiency and customer satisfaction.

Owner:NANJING BAOSTEEL SUMMIT METAL PRODUCTS CO LTD

Oil-gas separated-type balancing block

ActiveCN102162454BReduce oil dischargeExtended service lifeRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringMechanical engineering

The invention discloses an oil-gas separated-type balancing block which is internally provided with a channel, wherein the channel penetrates through two end surfaces of the balancing block and is communicated with the outer side wall of the balancing block. By adopting a compressor equipped with the balancing block provided by the invention can separate refrigerating machine oil from gas refrigerant in the operation process, thus the oil discharge amount of the compressor is reduced, not only can the amount of refrigerating machine oil in the shell of the compressor be ensured, the service life and dependance of the compressor are improved, but also the heat transfer effect and energy efficiency of an air conditioner can be improved.

Owner:PANASONIC WANBAO GUANGZHOU COMPRESSOR

Lubricating device for internal combustion engine

ActiveCN110872962BHigh outputGuaranteed oil quantityLiquid coolingMachines/enginesInternal combustion engineLubrication

A lubricating device for an internal combustion engine, including a connecting rod, a first oil passage, a second oil passage and a groove. The connecting rod includes a first surface provided on one end portion in the longitudinal direction of the connecting rod, and a bearing for supporting a pin shaft of a crankshaft or a pin shaft of a piston is fitted to the first surface. The first oil passage is configured to supply oil between the outer peripheral surface of the pin shaft and the inner peripheral surface of the bearing. The second oil passage is provided at one end and configured to inject oil. A groove is formed on the first surface or on the outer peripheral surface of the pin shaft, extends in the circumferential direction of the pin shaft, and collects oil. The second oil passage is connected to the groove.

Owner:MITSUBISHI MOTORS CORP

Method for making duck eggs tasty within short time

The invention relates to the technical field of food processing, and discloses duck eggs capable of being tasty within short time. The duck eggs are prepared from, by weight, 2-4 parts of cortex cinnamomi, 2-4 parts of star anise, 4-6 parts of fennel, 4-6 parts of Sichuan pepper, 800-1,000 parts of clear water, 50-60 parts edible salt, 80-100 parts of liquor, 30-34 parts of glucose and 40-50 partsof duck eggs. The cinnamon and the star anise are dried, aromas in the cinnamon and the star anise can be released completely, by removing moisture in the cinnamon and the star anise, the aromas in the cinnamon and the star anise are completely extracted, and after the fennel is ground into fennel powder and conveniently put in a stirrer, sealing fermentation of the duck eggs can be effectively ensured; external aromas can be effectively absorbed in the duck eggs, the aroma in the duck eggs can be effectively extracted, it is avoided that a present high-concentration soaking mode in the market is adopted for making the duck eggs, and nutrition in the duck eggs is absorbed, and therefore the oil amount in the duck eggs is effectively ensured, the amount of oil of the duck eggs in the mouthis ensured, and the quality is improved.

Owner:GAOYOU QINYOU EGG PROD

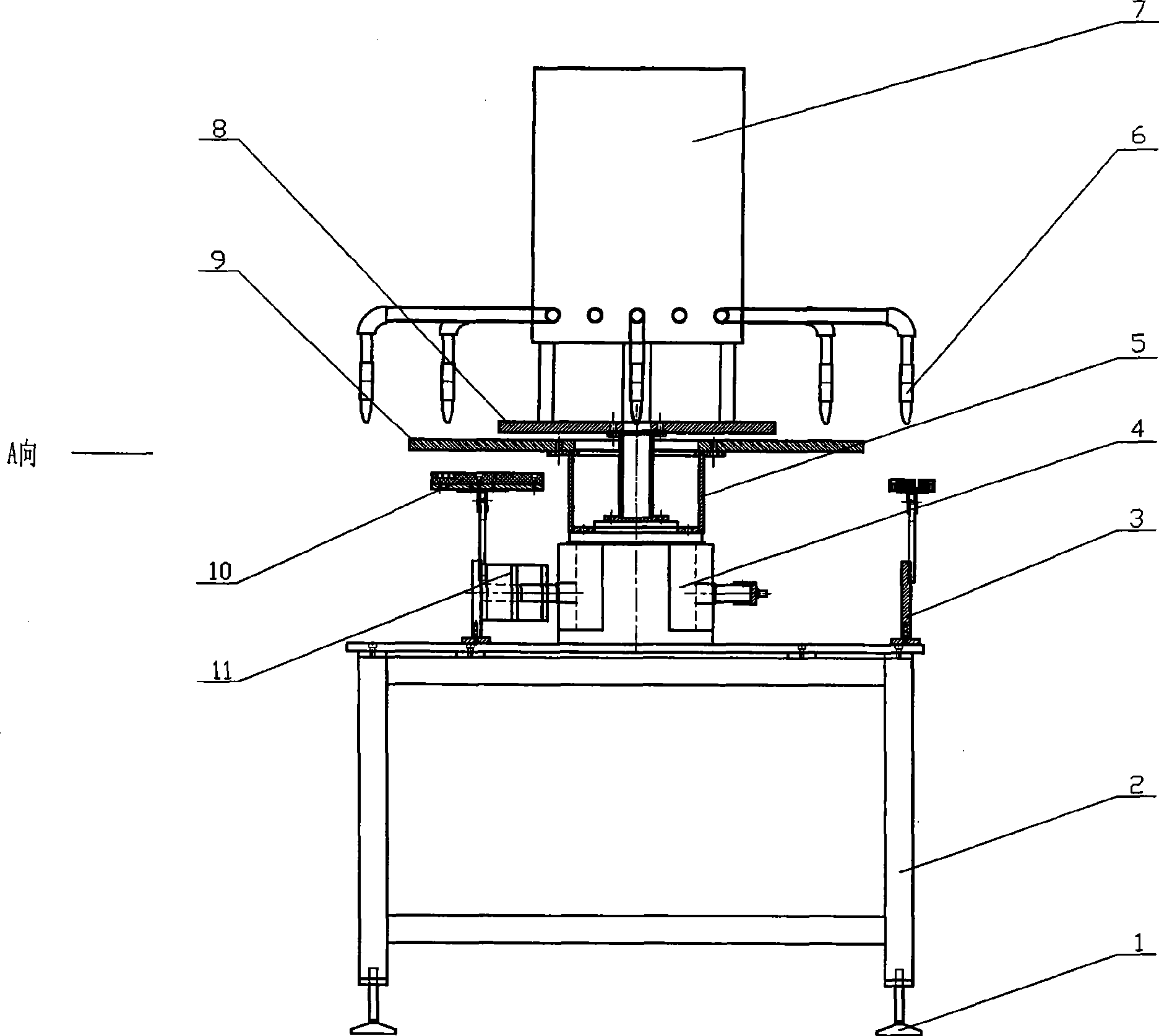

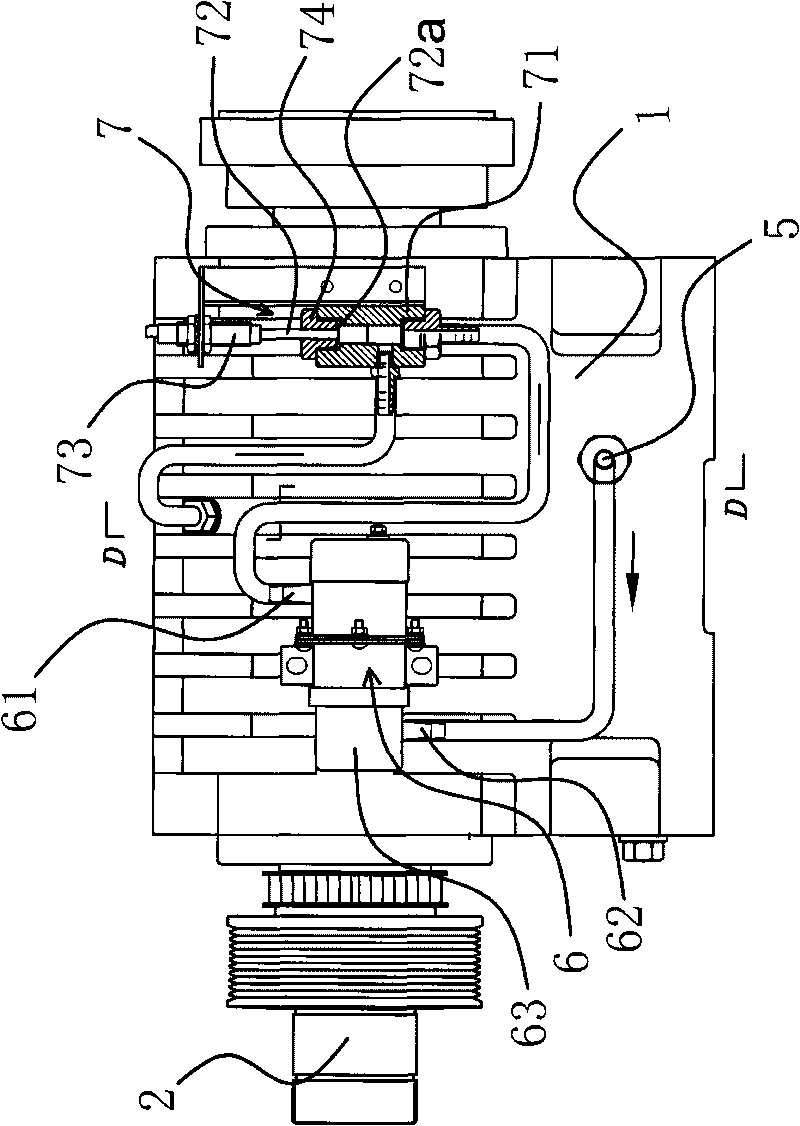

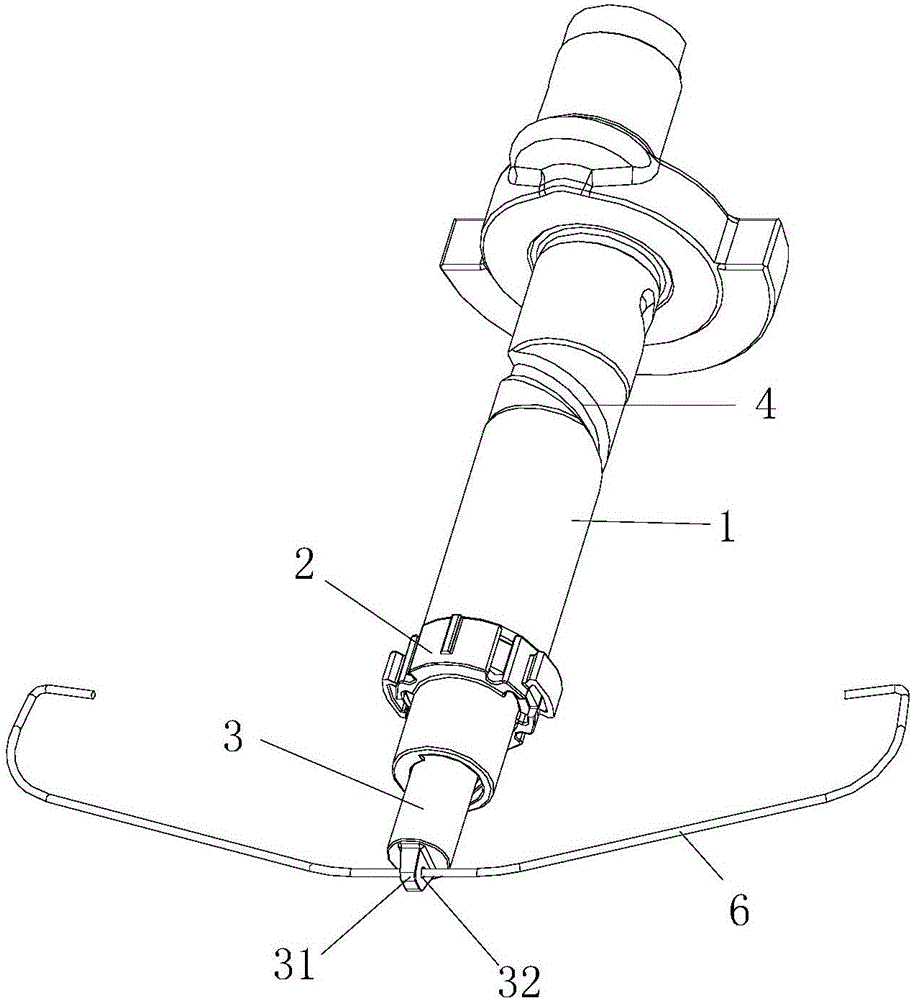

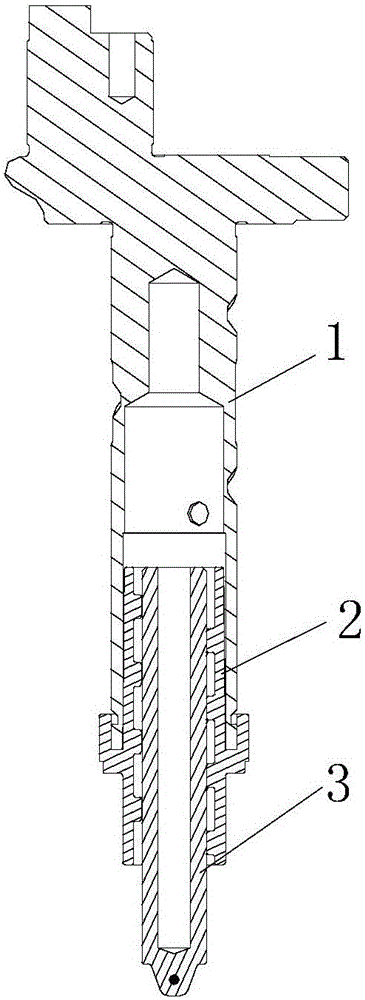

Oil pumping device for full-enclosed inverter compressor

ActiveCN105952619AGuaranteed oil quantityExtended service lifePositive displacement pump componentsPositive-displacement liquid enginesLow speedInverter compressor

The invention discloses an oil pumping device for a full-enclosed inverter compressor. The oil pumping device comprises a crank shaft, an oil suction pipe, a stator and a casing, wherein the oil suction pipe is arranged on the outer side of the lower part of the crank shaft in a sleeving manner; an oil suction pipe core is arranged in the oil suction pipe; the crank shaft, the oil suction pipe, the oil suction pipe core and the stator are positioned on the same axis; the crank shaft is in synchronous rotation with the oil suction pipe; the oil suction pipe core is fixed on the stator or the casing through a hanging spring. According to the oil pumping device disclosed by the invention, oil feeding resistance is low, oil feeding capacity of the inverter compressor in low rotating speed and high rotating speed can be guaranteed, lubricating and cooling are realized, and the service life of the compressor is prolonged.

Owner:QINGDAO WANBAO COMPRESSOR

A drive axle housing

Disclosed is a driving axle shell. The driving axle shell comprises an axle shell body, a main speed reducer shell (9) and axle tube parts (10). The axle shell body and the main speed reducer shell (9) are arranged in the middle, and the axle tube parts (10) are arranged at the two ends correspondingly. A half axle (4) can be installed in an inner hole of each axle tube part (10). The surface of the inner hole of each axle tube part (10) is provided with a spiral structure (8). Each spiral structure (8) is a single-head or multiple-head spiral flange or spiral groove. In addition, when the half axles (4) installed in the inner holes of the axle tube parts (10) rotate in order to drive a wheel hub (7) and a vehicle to go forwards, the direction of lubricating oil conveying through the spiral structures (8) points to one side of a main speed reducer (1). The structure is simple, the design is novel, and manufacturing is simple and convenient. The oil quantity in all cavities can be kept stable, sufficient lubrication of all components is ensured, and oil gas discharging and cooling effects on a wheel end mechanism (2) are particularly good. The service life of a driving axle system is effectively prolonged, and the driving axle shell can be suitable for all driving axles of which the wheel end mechanisms adopt oil lubrication.

Owner:DONGFENG COMML VEHICLE CO LTD

Rotary compressor

ActiveCN105909523ALow failure rateImprove reliabilityRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsFiltrationOil separation

The invention discloses a rotary compressor. A rotary compressing mechanism part and a motor are contained inside a sealed housing connected to a vent-pipe. The motor contains a stator and a rotor. The compressing mechanism part comprises a cylinder provided with a compression chamber, a crankshaft and an oil separator, wherein the cylinder is provided with a piston and a slip sheet; the crankshaft is driven by the rotor and eccentrically rotates the piston; and the oil separator rotates together with the crankshaft or the rotor and is provided with an oil filter. High pressure gas discharged out of the compression chamber flows through the oil filter and then flows into the vent-pipe. According to the rotary compressor of the embodiment, high pressure gas discharged out of the compression chamber can undergo oil separation and oil filtration. Thus, amount of oil in the high pressure gas discharged out of the vent-pipe is greatly reduced, amount of oil inside the rotary compressor is guaranteed, failure rate of the rotary compressor is decreased, and reliability and efficiency of the rotary compressor are boosted.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

Fully automatic wax oil mixing and canning machine

ActiveCN101533724BGuaranteed oil quantityNo pollution in the processCapacitor manufactureWaxSprocket

The invention discloses a fully automatic wax and oil mixture can packing machine, which mainly adopts a motor and a dividing mechanism which are fixed on a platform by bolts respectively. A first chain wheel is arranged on a main shaft of the motor; a second chain wheel is arranged on a main shaft of the dividing mechanism; and the first chain wheel and the second chain wheel are connected by a chain. The motor is connected with an energized overload clutch through the chain; and the energized overload clutch is connected with the dividing mechanism through a shaft. A clamping hand is arranged on sixteen work positions of a rotating table through the bolts respectively; and the rotating table is arranged on the dividing mechanism through a connecting flange. A round platform surface is fixed on the rotating table through the bolt; an oil filling device is fixed on the rotating table; and an oil bucket is fixed on the round platform surface through a bracket. A loading device and an unloading device are fixed on the platform through the bolts; and a coder is connected with an output shaft of the dividing mechanism through a soft connecting piece. The can packing machine can realize multi-station oil filling, and has the characteristics of compact, simple and reasonable structure, high production efficiency, exact oil filling amount, and the like.

Owner:WUXI HONGGUANG CAPACITOR

A dry oil sump oil supply device suitable for high-inclination diesel engines

ActiveCN107191240BIncrease working inclinationAchieve isolationOilsumpsMachines/enginesCombustionInternal combustion engine

The invention belongs to the internal field of internal combustion engines and provides a dry type oil pan oil supply device applicable to a large-inclination-angle diesel engine. According to the dry type oil pan oil supply device applicable to the large-inclination-angle diesel engine, two partition plates perpendicular to the bottom face of a dry type oil pan are arranged at the bottom of the dry type oil pan; an oil storing groove is formed between the two partition plates, and the two sides of the oil storing groove are each provided with an oil collecting groove of an open structure; an oil inlet pipe is arranged in each oil colleting groove; the flange ends of the oil inlet pipes are connected with an oil inlet of a two-stage parallel connection gear pump; one end of an oil outlet pipe arranged in the oil storing groove stretches out of the oil storing groove and is connected with an oil outlet of the two-stage parallel connection gear pump; the dry type oil pan oil supply device is further provided with an oil sucking pipe communicated with an engine oil pump of a diesel engine lubricating system; and the other end of the oil sucking pipe is connected with a suction filter located at the bottom of the oil storing groove in an inserted connection manner. The dry type oil pan oil supply device applicable to the large-inclination-angle diesel engine effectively solves the problem that under the conditions that the speed change and the inclination are large during turning of the diesel engine, normal lubrication of the diesel engine cannot be achieved, and the inclination angle of work of the diesel engine is greatly improved.

Owner:HENAN DIESEL ENGINE IND

Energy-saving and environment-friendly oil tank refueling auxiliary equipment for electromechanical equipment

InactiveCN112849721AAvoid overfilling and spillingGuaranteed uptimeContainer decorationsLevel indicationsEquipment useControl engineering

The invention relates to the technical field of electromechanical oil tank refueling equipment, in particular to energy-saving and environment-friendly oil tank refueling auxiliary equipment for electromechanical equipment. The auxiliary equipment comprises a working frame, a recovery tank is fixedly connected to the inner bottom surface of the working frame, a positioning rotating wheel is rotationally connected into the working frame through a shaft, a sliding rotating wheel is inserted into the positioning rotating wheel, a transmission rod is movably connected to the front surface of the sliding rotating wheel through a shaft, a traction rope is fixedly connected to the front surface of the transmission rod, a fixed sliding rail is fixedly connected to the position, located outside the transmission rod, in the working frame, a baffle plate is used for shielding an oil filling port, and oil injection is automatically stopped, so that the oil quantity of an oil tank in the equipment can be guaranteed, meanwhile, excessive oil injection overflow is avoided, normal operation of the equipment can be well guaranteed, and the oil injection monitoring effect is achieved, and whether the oil tank is damaged or not can be well judged by shifting an ammeter outside the equipment, so that timely maintenance is facilitated.

Owner:杭州砥行机械自动化有限公司

Scroll type pump body, compressor and air conditioner

PendingCN109441804AGuaranteed lubrication effectImprove work performanceRotary piston pumpsRotary piston liquid enginesWork PerformancesCrankshaft

The invention provides a scroll type pump body, a compressor and an air conditioner. The scroll type pump body comprises a static disc and a dynamic disc which are engaged with each other and a supporting rack used for supporting the static disc and the dynamic disc, a crankshaft is connected with the supporting rack through a bearing and forms a bearing cavity, the side, facing the supporting rack, of the dynamic disc is structured with a lubricating oil passage, a back pressure cavity is formed between the dynamic disc and the supporting rack, and the lubricating oil passage can cut throughthe bearing cavity and the back pressure cavity alternatively along with sliding of the dynamic disc. According to the scroll type pump body, the compressor and the air conditioner, the lubricating oil quantity of the static disc and the dynamic disc can be significantly increased, the pump body lubricating effect is guaranteed, and then the working performance of the pump body is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

A drive axle half shaft for a vehicle

ActiveCN105667212BStable oil quantityGuaranteed oil quantityShaftsGear lubrication/coolingReduction driveReducer

A half shaft of a drive axle for a vehicle, which belongs to the half shaft used for a drive axle of an oil-lubricated structure, comprising a shaft body (41) and key joints located at both ends of the shaft body (41), or including a shaft body (41), located at The key joint at one end of the shaft (41) and the flange (43) at the other end of the shaft (41), the outer surface of the shaft (41) is provided with a helical structure (8), and when the shaft (41) When the wheel hub (7) and the vehicle are driven forward to rotate, the helical structure (8) conveys the lubricating liquid to the side of the final reducer (1). The structure is simple, the design is novel, and the production is simple and convenient. It can keep the oil volume of each cavity stable and ensure that all parts are fully lubricated. Especially, the effect of exhausting oil and gas and cooling the wheel end mechanism (2) is good, effectively prolonging the use of the drive axle system. It can be applied to all oil-lubricated vehicle drive axles.

Owner:DONGFENG COMML VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com