A drive axle housing

A technology for driving axle housings and axle housings, which is applied in vehicle parts, transportation and packaging, axles, etc., can solve the problems of poor heat dissipation of the wheel end mechanism, high temperature oil and gas, many wheel end mechanism failures, and short service life, and achieves cooling effect. Good, low cost, easy to make effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

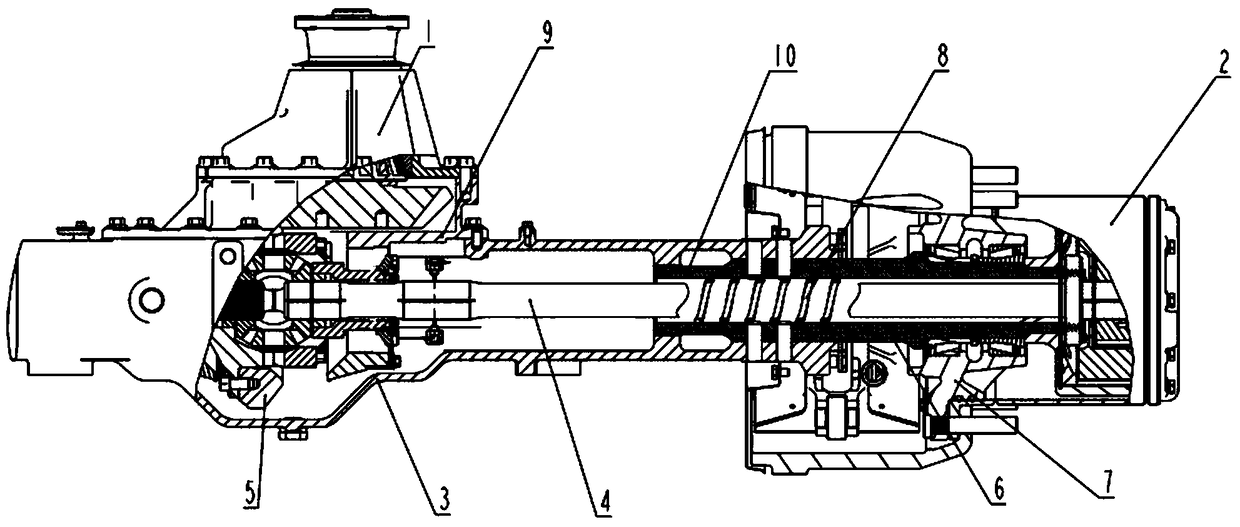

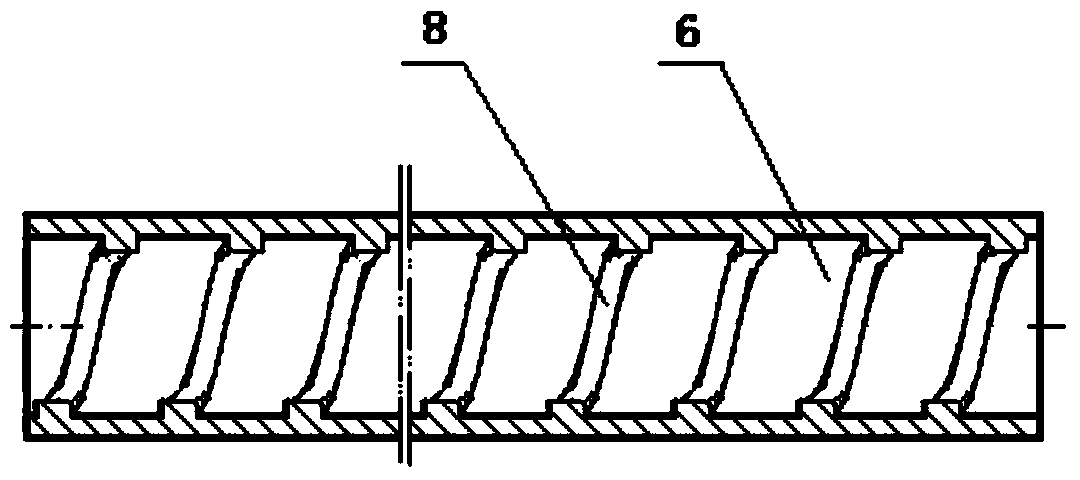

[0031] see figure 1 , the drive axle housing described in the present invention includes the axle housing in the middle and the final reducer housing 9 and the shaft tube parts 10 at both ends, and the axle shaft 4 can be installed in the shaft tube part 10, and the shaft tube part 10 A helical structure 8 is provided on the surface of the inner hole, and the helical structure 8 is a single-headed helical rib, and when the axle shaft 4 installed in the shaft tube part 10 rotates due to driving the drive axle and the vehicle forward , the direction in which the helical structure 8 axially transports lubricating oil points to one end of the final reducer 1 . The direction of rotation of the spiral structure 11 can be judged according to the left-hand and right-hand rules of the existing spiral material delivery direction. The direction of material delivery, the direction held by the four fingers is the direction of shaft rotation, and the direction of rotation of the helical s...

Embodiment 2

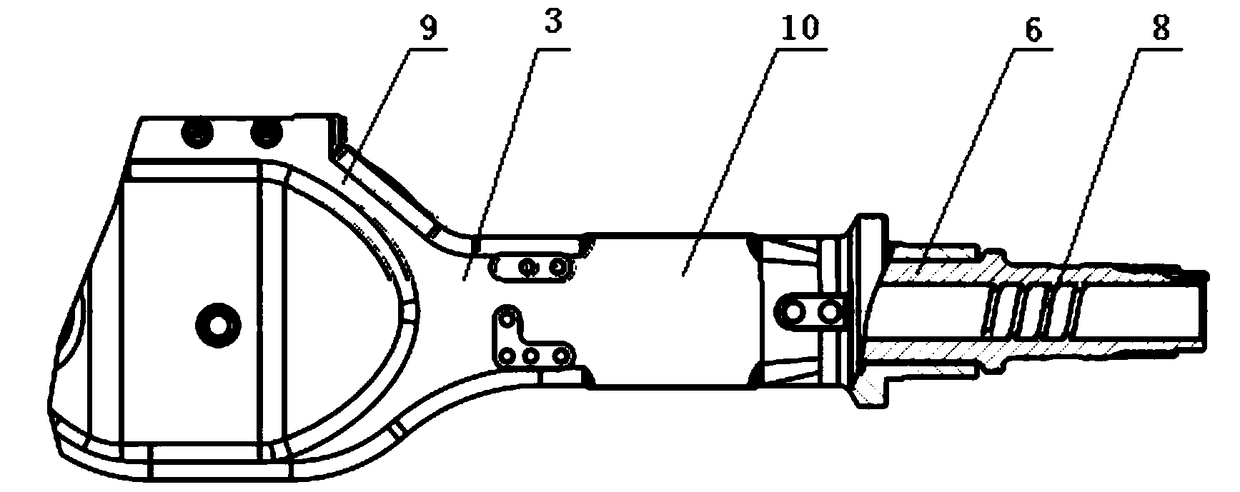

[0038] see Figure 4 , combined with figure 1 , figure 2 , the drive axle housing 3 is expanded into a form axle housing, the middle part of the drive axle housing 3 is expanded, and the two ends are steel pipes that have been thinned by rolling. At this time, the shaft tube part 10 is thinned by rolling steel pipe, that is, the inner hole of the shaft tube part 10 is a variable cross-section hole, and a helical structure 8 is arranged on the inner hole surface of the steel pipe, and the helical structure 8 is a spiral structure 8 hovering on the shaft tube part, that is, the inner hole surface of the steel pipe. Single-headed helical ribs, on the shaft tube portion 10 at both ends of the drive axle housing 3, the direction of rotation of the helical structure is opposite, that is, Figure 4 The forward direction of drive axle 3 shown in is the direction away from the reader, Figure 4 The direction of rotation of the helical structure 8 on the right axle tube portion 10 ...

Embodiment 3

[0041] see image 3 , combined with figure 1 , figure 2 , the drive axle housing is a stamped and welded axle housing, and the axle housing is composed of the main parts of the axle housing, the leaf spring seat, the half shaft sleeve, the rear cover, etc. At this time, the shaft tube part 10 may include the half shaft A part of the overhanging section of the bushing and the main part of the axle housing can also directly use the half bushing as the shaft tube part 10, that is, the inner hole of the shaft tube part 10 is a hole of equal section, and the half shaft bushing A helical structure 8 is provided on the surface of the inner hole, and the helical structure 8 is a single-headed helical groove hovering on the surface of the inner hole of the shaft tube part 10, that is, the half-axle sleeve. 10, the direction of the helical structure is opposite, that is, image 3 The forward direction of drive axle 3 shown in is the direction away from the reader, image 3 The dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com