A silent diesel engine capable of realizing miniaturization and light weight

A light-weight technology for diesel engines, which is applied to mechanical equipment, intake mufflers, engine components, etc., can solve the problem of poor cooling effect of the air ducts at the cylinder head and cylinder holes and the air ducts at the bottom of the box, and can not guarantee the overall performance of the diesel engine. Heat dissipation effect, slow cooling air flow rate and other issues, to achieve the effect of low cost, simple setting, and reduced operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

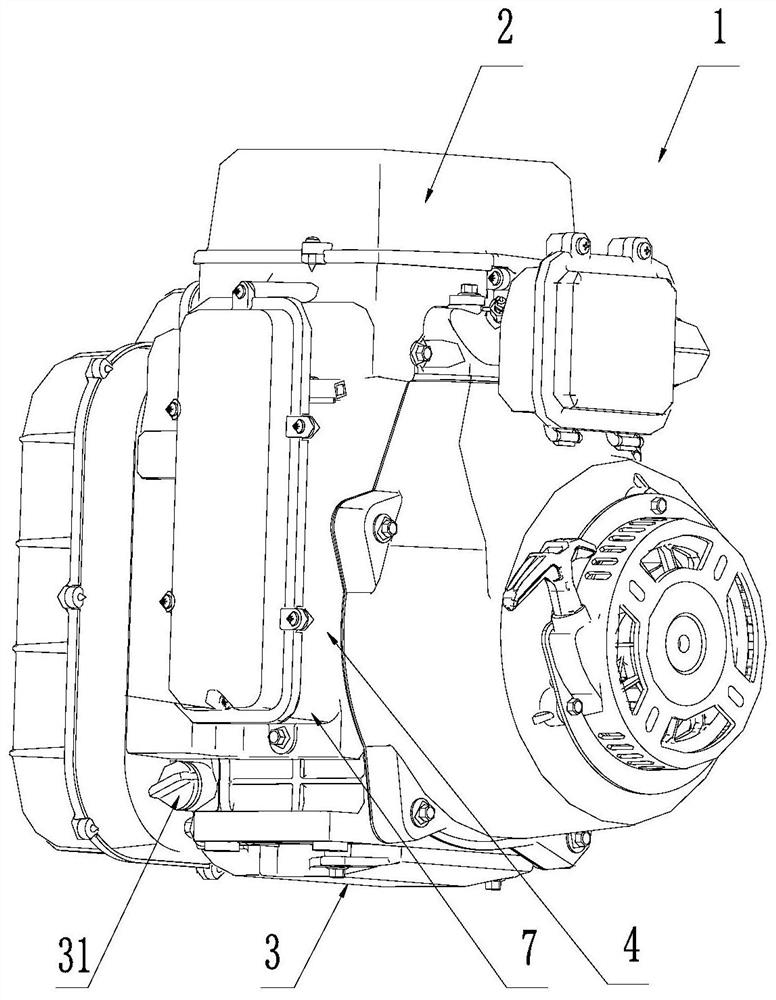

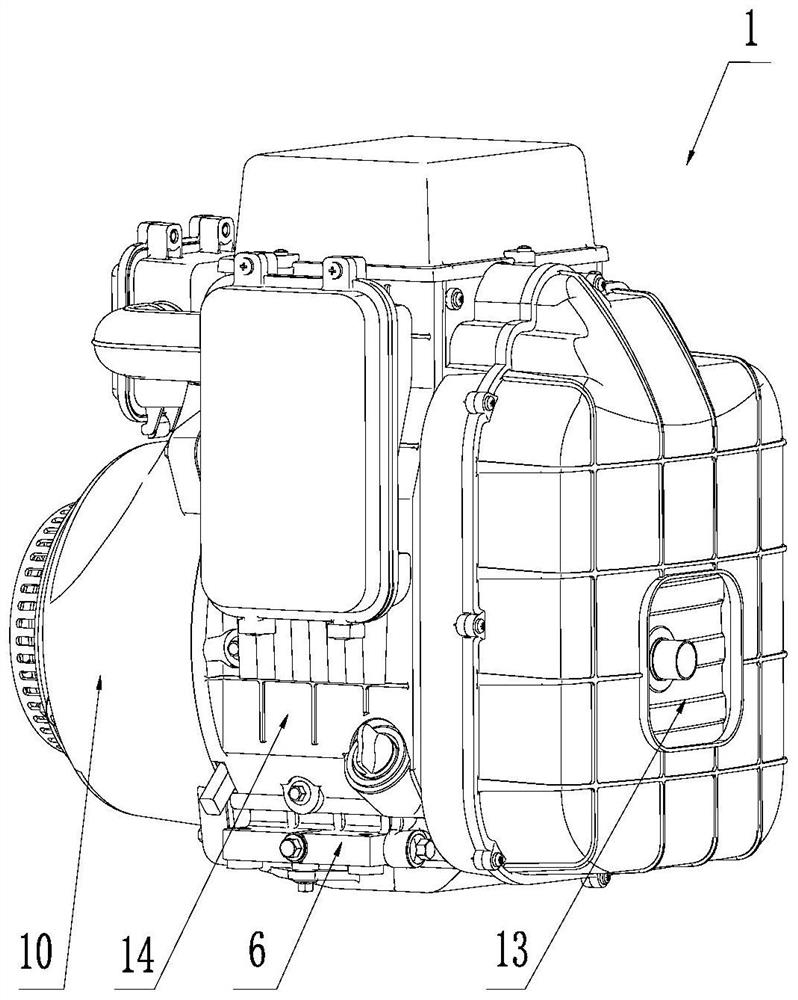

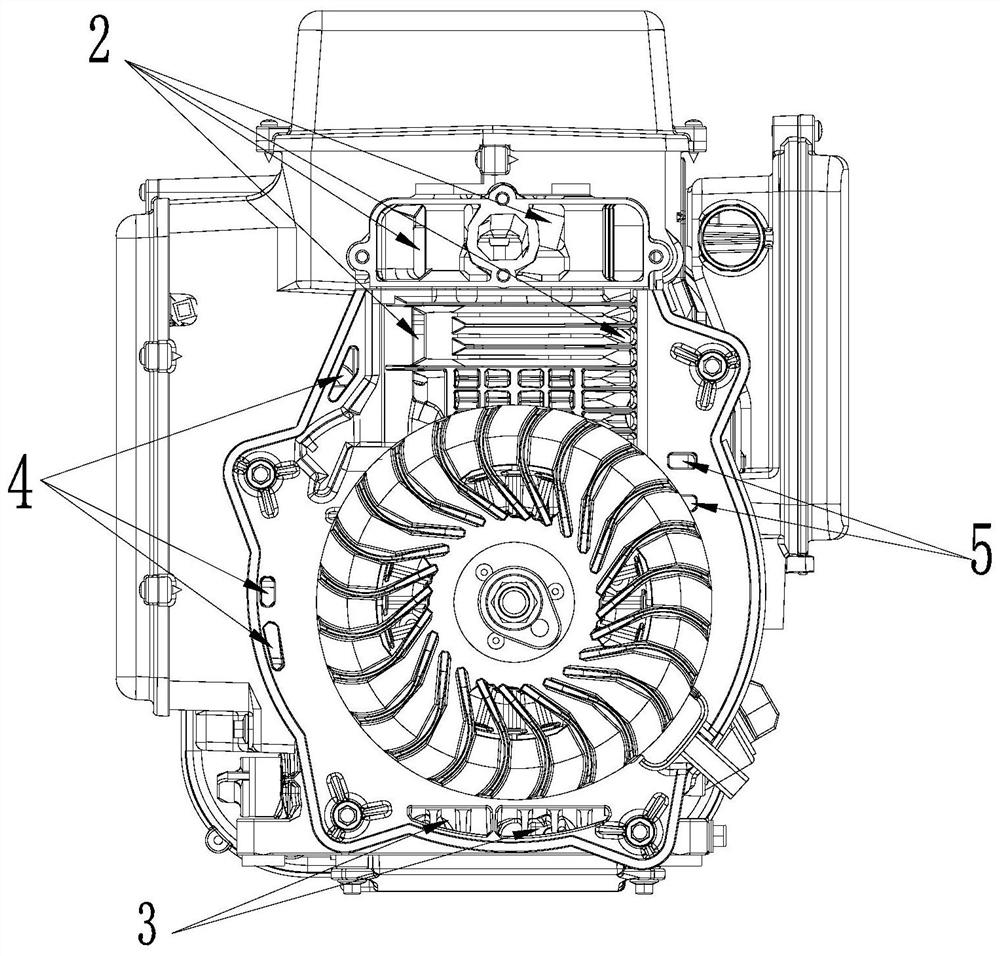

[0024] like Figure 1-11 A silent diesel engine that can realize miniaturization and light weight is shown. Its main body is a diesel engine body 1. The diesel engine body 1 is provided with a cooling air duct system and a speed regulating device. The diesel engine body 1 is also provided with a lubrication system.

[0025] The cooling air duct system includes the cylinder head and cylinder hole air duct 2, the air duct 3 at the bottom of the box, the side air duct 4 of the high-pressure oil pump and the side air duct 5 of the air filter.

[0026] Cylinder head and cylinder hole position air duct 2: The cooling air enters from the starting cover 10, cools the cylinder head and the cylinder hole position, and finally enters the muffler 13 chamber to merge and discharge.

[0027] Air duct 3 at the bottom of the case: the cooling air enters from the starting cover 10, passes through the lower side of the crankcase 6, cools the lubricating oil in the crankcase 6, and finally enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com