Steel collar combination with zero manual oiling for twisting machinery

A technology of twisting machine and assembly, applied in textiles and papermaking, etc., can solve the problems of poor uniformity, easy contamination of yarn, low efficiency, etc., to achieve stable oil supply, prevent pollution, and reduce oil consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

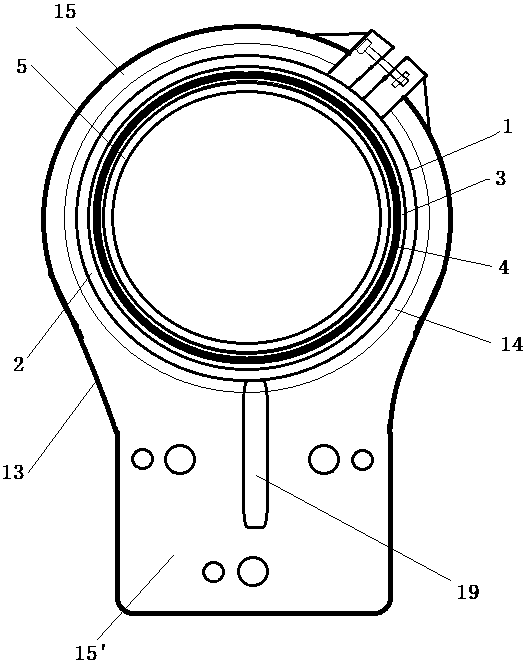

[0027] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] like figure 1 As shown, a twister ring ring assembly free of manual oiling is composed of a ring ring 1 and a ring post 13.

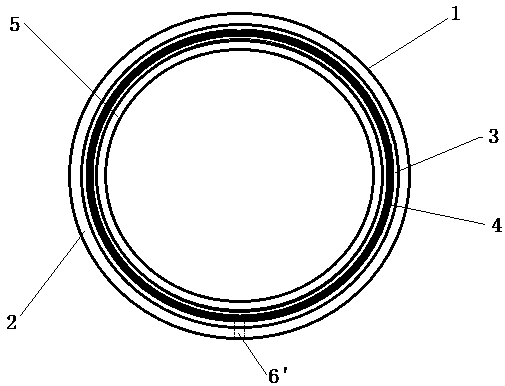

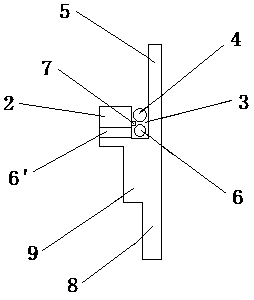

[0029] like Figure 2-3 As shown, the ring ring 1 includes a ring ring body, and the ring ring body is integrally formed by an inner ring 5, a first-stage ring 8, a second-stage ring 9 and a third-stage ring 2, the The first step ring 8, the second step ring 9 and the third step ring 2 form steps from bottom to top in turn; the inner ring 5 is located inside the ring ring body, while the inner ring 5 Higher than the third-stage ring 2, the inner surface of the inner ring 5 and the first-stage ring 8 are on the same plane, an oil groove 3 is provided between the inner ring 5 and the third-stage ring 2, and the oil delivery line 6 Wrapped around in the oil groove 3, the sealing ring 4 seals the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com