Application of fuel oil pressure-stabilizing system in continuous melting furnace

A melting furnace and voltage stabilizing technology, which is applied in the direction of liquid fuel supply/distribution, combustion methods, liquid variable capacity machinery, etc., can solve problems such as disturbance disturbance, influence on control effect, automatic control failure, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

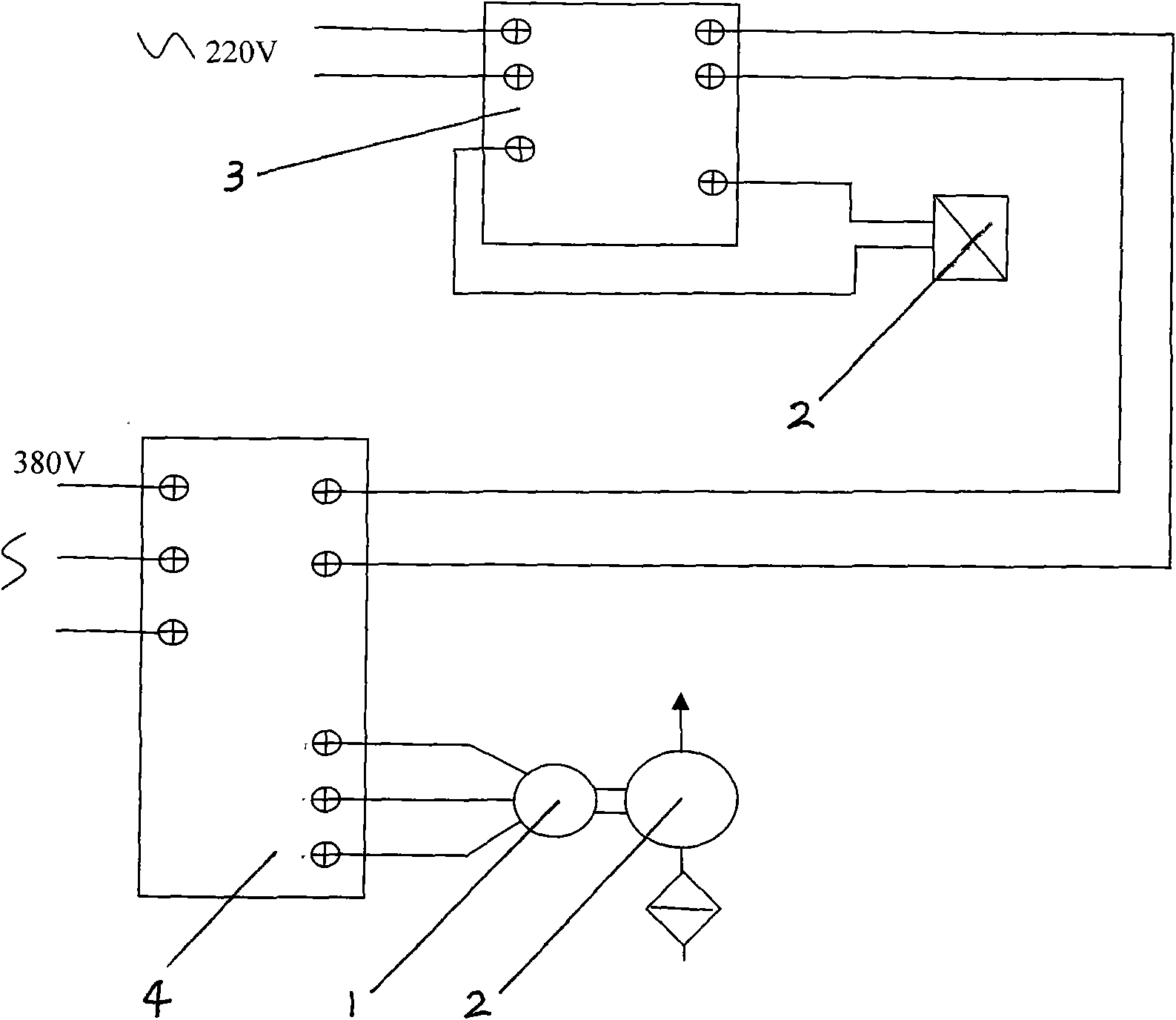

[0007] Such as figure 1 As shown, the present invention is mainly composed of an oil pump 1, a pressure sensor 2, a digital controller 3, and a frequency converter 4 to form a standard closed-loop circuit. The working process is: a pressure reference value is set by the digital controller, and the digital controller references the pressure The value is output to the frequency converter with a DC signal, and the output voltage of the frequency converter is used to control the speed of the motor of the oil pump with frequency conversion, and the outlet pressure of the oil pump changes, so as to obtain a suitable and stable oil pressure signal, which is then transmitted to the digital controller through the pressure sensor, and the control obtained The output value is used for the next round of closed loop control, so as to control the oil pressure at the set pressure reference value and stabilize the oil pressure.

[0008] When working, the oil pump 1 is installed on the fuel pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com