A vehicle half shaft

A vehicle and axle body technology, which is applied in the directions of axles, axles, wheels, etc., can solve the problems of poor heat dissipation of the wheel end mechanism, high temperature oil and gas, increased temperature of the wheel end mechanism, and short service life, and achieves the effect of exhaust and heat dissipation. Enhancement, increased heat generation, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

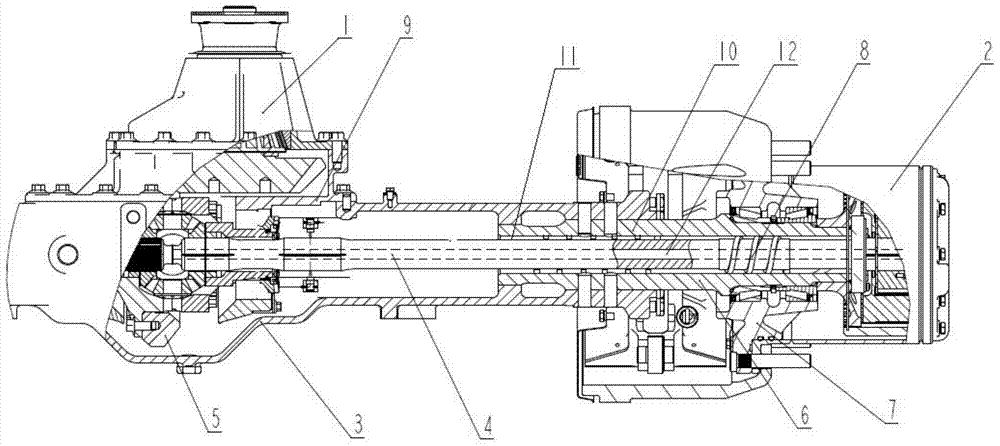

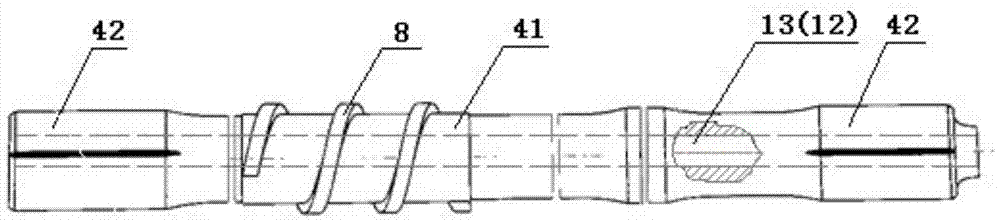

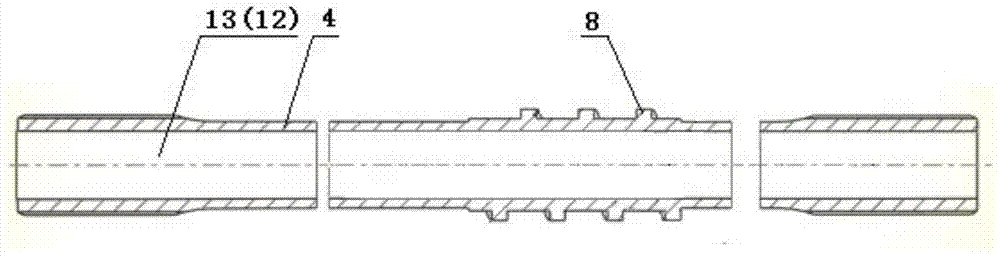

[0059] see figure 1 , figure 2 , image 3 , Figure 12 , the structure in which the half shaft 4 of the first structure of the present invention cooperates with the first shaft tube part 10, the vehicle half shaft of the present invention adopts figure 1 Axis 4 shown and figure 2 , image 3 The structure of the shaft body 41 shown in the figure and the key connection part 42, the outer surface of the shaft body 41 is provided with a helical structure 8, the center of the shaft body 41 is provided with a hollow inner hole that runs through the entire length, that is, the shaft inner channel 12, and the shaft body 41 The left end of the upper hollow inner hole leads to the wheel end mechanism 2, and the right end leads to the final reducer 1. The hollow inner hole is the diameter of the channel 12 in the shaft and the helical structure 8 in it so that the flow rate of the lubricating liquid through the hollow inner hole is slightly smaller than that of the shaft. The fl...

Embodiment 2

[0063] see Figure 13 , combined with figure 1 , Figure 4, is the structure that the half shaft 4 of the second structure of the present invention cooperates with the first shaft tube part 10; A helical structure 8 is provided in the inner hole, that is, the inner channel 12 of the shaft. The helical structure 8 is a single-headed or multi-headed spiral rib or spiral groove arranged in the shaft body 41 and the inner shaft hole 13 of the half shaft 4. As a result, there are two sets of helical structures 8 on the half shaft 4, one set of helical structures 8 is set on the outer surface of the half shaft 4, and the other set of helical structures 8 is set in the inner channel 12 of the shaft, and when the shaft body 41 rotates, The two groups of helical structures 8 transport lubricating liquid in opposite directions.

Embodiment 3

[0065] see Figure 14 , combined with figure 1 , the structure in which the half shaft 4 of the first structure of the present invention cooperates with the shaft tube part 10 of the second type. The structure of the half shaft 4 in this embodiment is exactly the same as that in Embodiment 1, but the half shaft sleeve 6 is different from that of Embodiment 1. A group of helical structures 8 are also arranged in the inner hole of the half shaft sleeve 6 in this embodiment. The set of helical structures 8 has the same helical direction as the helical structures 8 on the outer surface of the half shaft 4 . Other structures in this embodiment are basically the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com