Rotary compressors with low exhaust oil content

A rotary compressor and oil content technology, applied in the field of rotary compressors, can solve the problem of high oil content in the exhaust, and achieve the effects of reduced oil content in the exhaust, stable oil volume, and good speed change characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

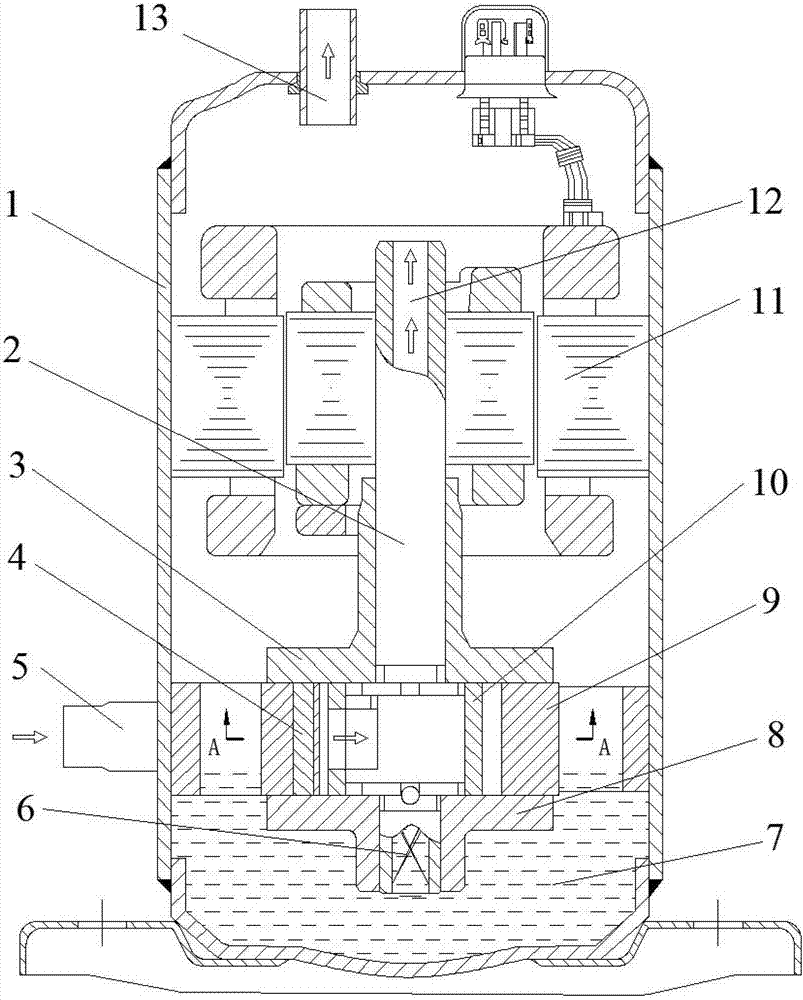

[0027] figure 1 The rotary compressor with low exhaust oil content shown includes a housing 1 , a crankshaft 2 , an upper end cover 3 , a guide rail 4 , a lower end cover 8 , a cylinder 9 , a swing rotor 10 and a motor 11 . An air intake pipe 5 and an exhaust pipe 13 are welded on the housing 1 . There is an axial oil passage below the crankshaft 2, and an oil-absorbing sheet 6 is housed in the axial oil passage. There is an oil pool 7 at the bottom of the housing 1, and the oil-absorbing sheet 6 and the axial oil channel are always under the liquid level of the oil pool 7. The compressor is driven by a motor 11, and the rotor of the motor is coaxial with the compressor. During the working process of the compressor, the air is sucked from the suction pipe 5, and enters the working chamber composed of the upper end cover 3, the guide rail 4, the lower end cover 8, the cylinder 9 and the swing rotor 10 through the air intake hole on the cylinder 9. After compression, , discha...

Embodiment 2

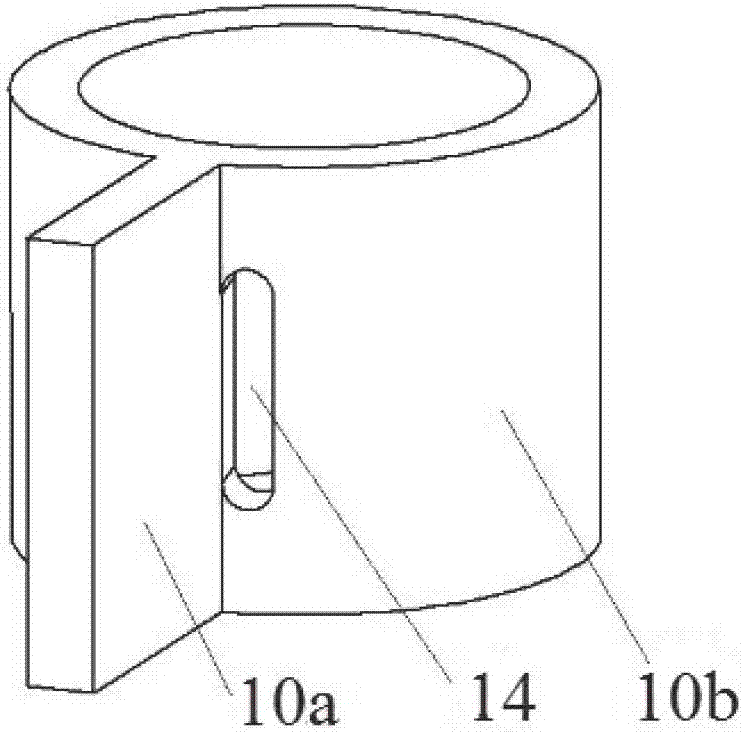

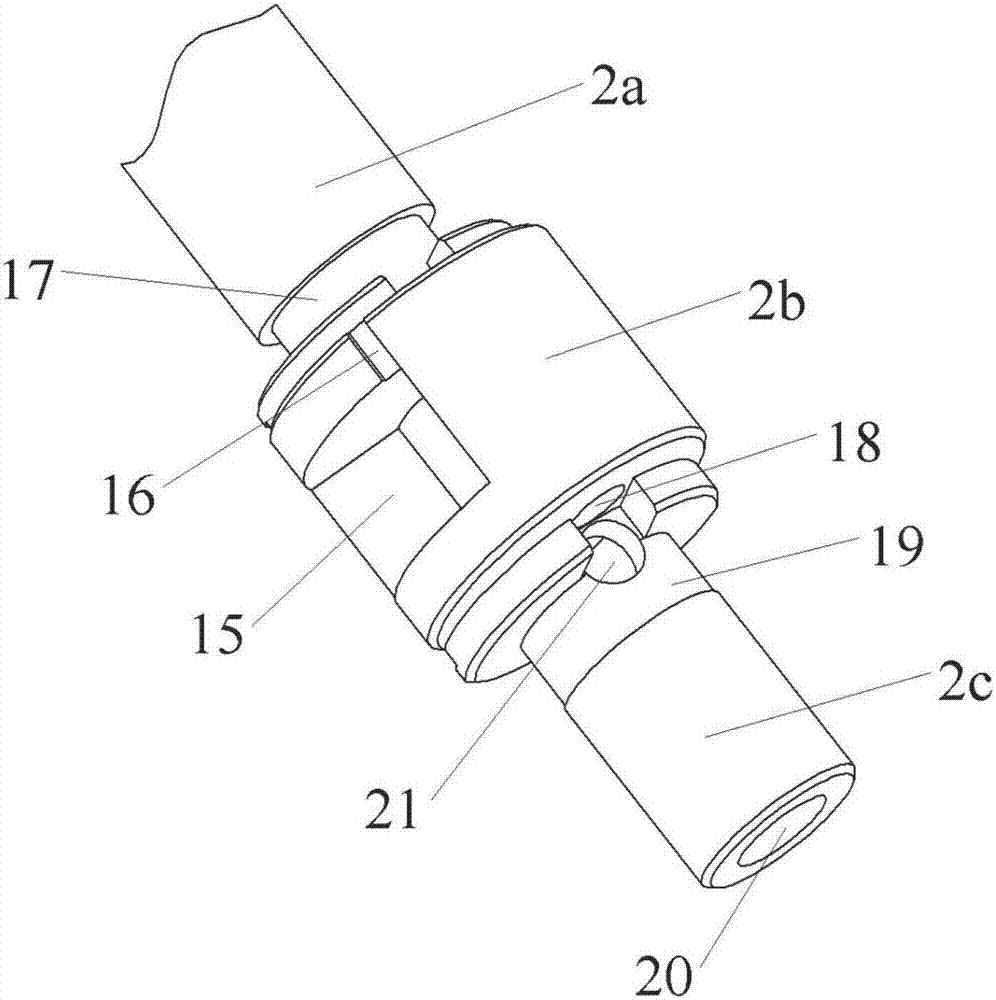

[0037] A rotary compressor with low exhaust oil content includes a casing 1 , a crankshaft 2 , an upper end cover 3 , a guide rail 4 , a lower end cover 8 , a cylinder 9 , a swing rotor 10 and a motor 11 . The crankshaft 2 includes a main shaft 2a, an eccentric wheel 2b and a secondary shaft 2c, and the swing rotor 10 is sleeved on the eccentric wheel 2b. Air intake hole 24 is arranged on the cylinder 9, and exhaust hole 14 is arranged on the swing rotor 10. An axial air channel 12 is opened in the center of the main shaft 2a, and an axial oil channel 20 is opened in the center of the auxiliary shaft 2c. An exhaust cavity 15 and an oil return groove 16 are opened on the eccentric wheel 2b. The exhaust chamber 15 communicates with the axial air passage 12 . One end of the oil return groove 16 communicates with the exhaust chamber 15 , and the other end communicates with the upper oil chamber 25 jointly formed by the upper end cover 3 , the swing rotor 10 and the crankshaft 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com