Automatic lubricating system and method of motor of ventilator

An automatic lubrication and fan technology, applied in the direction of engine lubrication, lubricating oil containers, lubricating parts, etc., can solve the problems of manual oiling, such as difficulty in manual oiling, heavy workload, and uncertain supply of oiling volume, to achieve fine management , timely and reliable lubrication, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

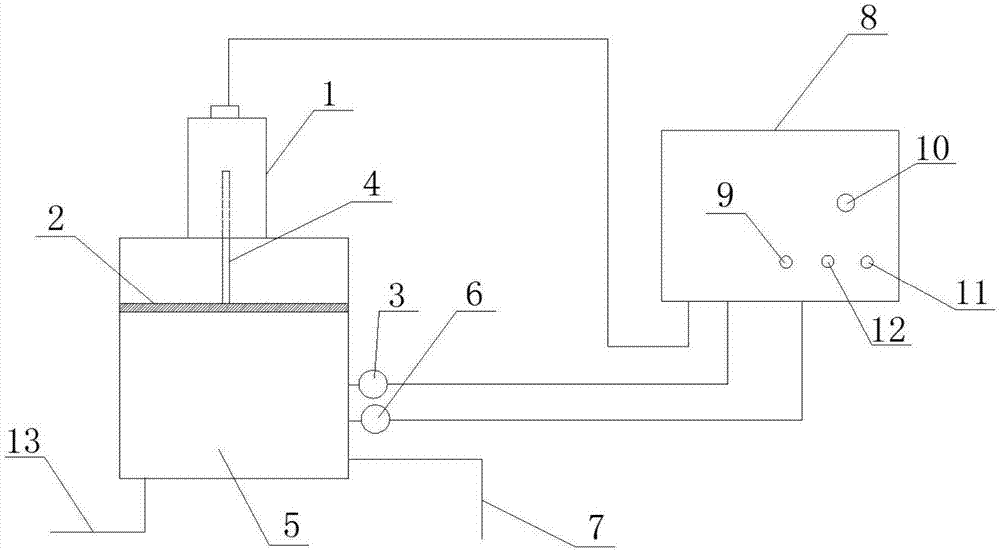

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0023] see figure 1 , an automatic lubrication system for fan motors, including an oil storage tank 5 for storing lubricating oil. An oil pipe 13, an oil injection pipe 7 is connected to the lower side of the oil storage tank 5, and the outlet end of the oil injection pipe 7 is connected to the oil injection hole in the fan motor bearing chamber, and the oil storage tank 5 is provided with a pressure plate for pushing down the lubricating oil 2. The upper part of the oil storage tank 5 is provided with a push motor 1, the output end of the push motor 1 is connected with a push rod 4, the free end of the push rod 4 is connected to the center of the pressure plate 2, and the push rod 4 is perpendicular to the plane where the pressure plate 2 is located , the push motor 1 is connected to the controller 8 through a cable, the temperature sensor 6 and the pressure sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com