Lubricating device for internal combustion engine

A lubricating device and internal combustion engine technology, which is applied in the direction of engine lubrication, pressure lubricant, engine cooling, etc., can solve the problems of improving the internal combustion engine, large axial length of the pin shaft, and increased length of the pin shaft, and achieve the effect of improving the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

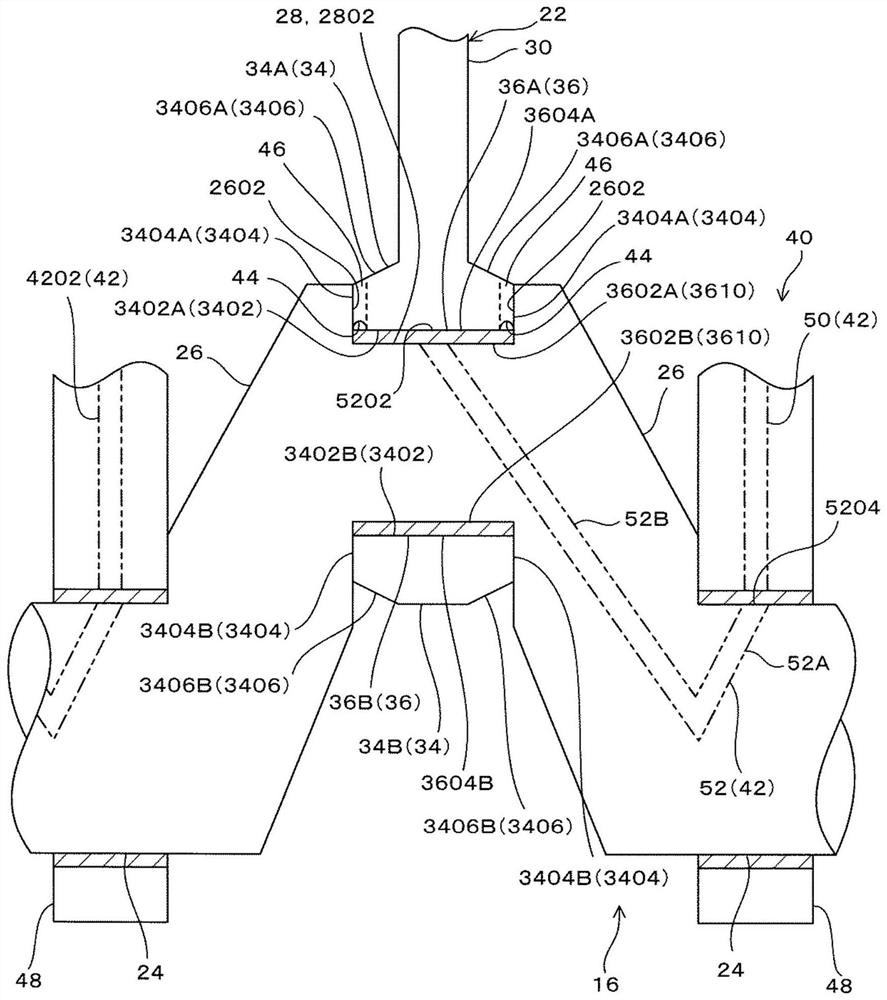

[0028] Such as Figure 8 As shown, internal combustion engine 10 includes: cylinder block 14 attached to crankcase 12, cylinder head (not shown) attached to cylinder block 14, crankshaft 16 rotatably supported by cylinder block 14, attached to cylinder block 14 and form the cylinder liner 18 of the cylinder wall surface 1802; the piston 20 slidably disposed on the cylinder wall surface 1802; and the connecting rod 22 connecting the crankshaft 16 and the piston 20.

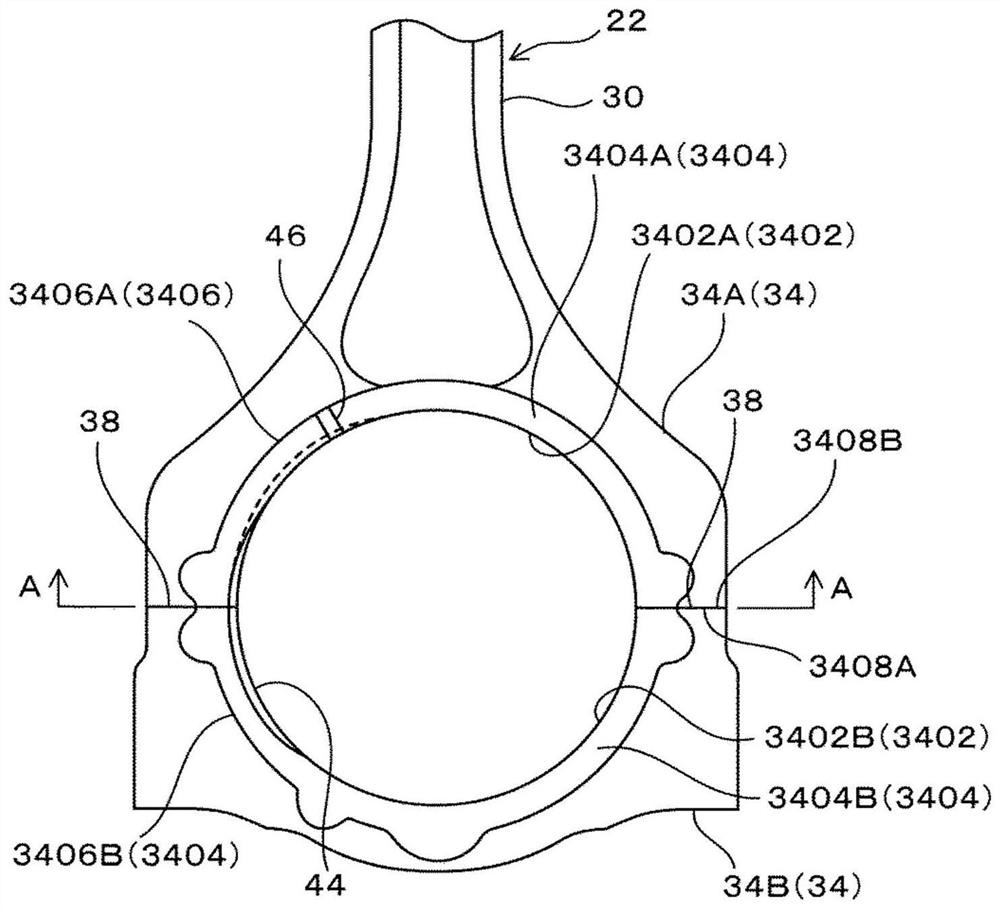

[0029] Such as figure 1 As shown, the crankshaft 16 includes a plurality of pairs of crank arms 26 disposed on the crank journal 24 and a plurality of pins 28 disposed between the top ends of the pairs of crank arms 26 .

[0030] Such as Figure 8 As shown, pin 28 of crankshaft 16 and piston pin 2002 of piston 20 are connected by connecting rod 22 .

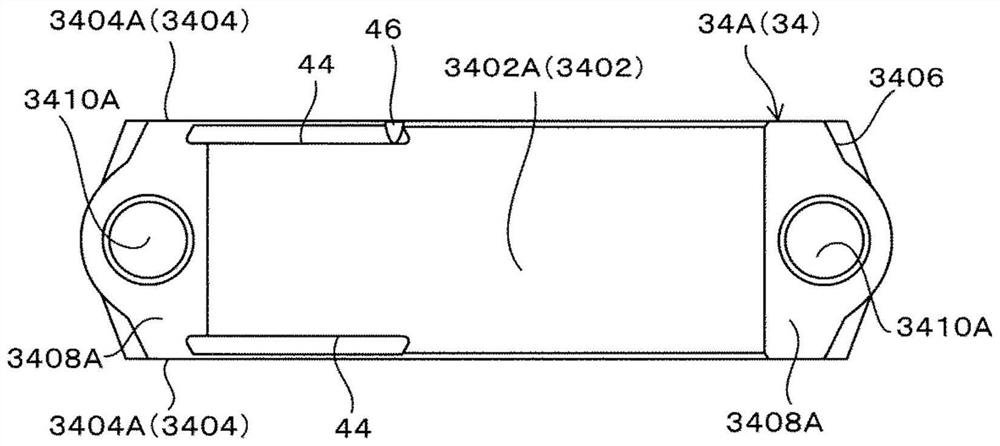

[0031] Such as figure 1 As shown, annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com