Oiling agent for semi-continuous spinning of viscose filament yarn as well as preparation method and application of oiling agent

A semi-continuous, spunbond technology, used in textiles and papermaking, chemical post-processing of cellulose/protein rayon, fiber processing, etc. It is not conducive to the application of high-end textiles and the use of downstream customers, so as to achieve the effect of clear and transparent appearance, prevention of adhesion and less sagging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

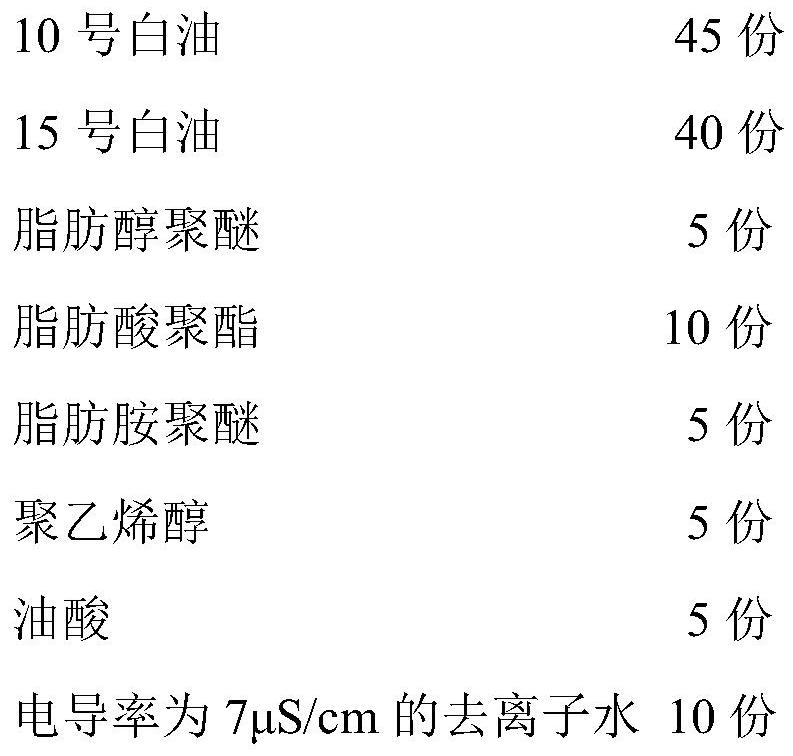

[0021] (1) Raw materials

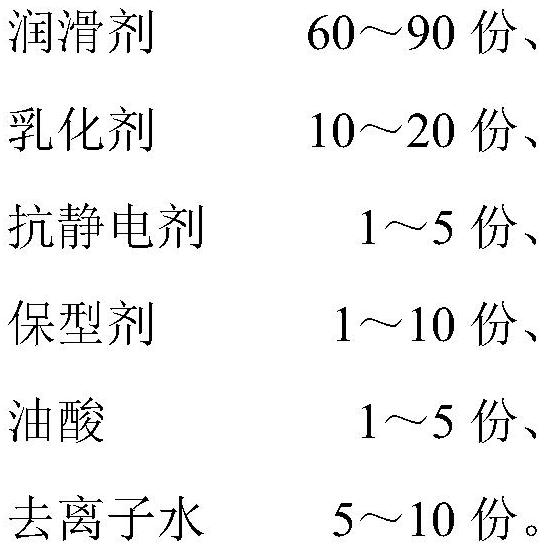

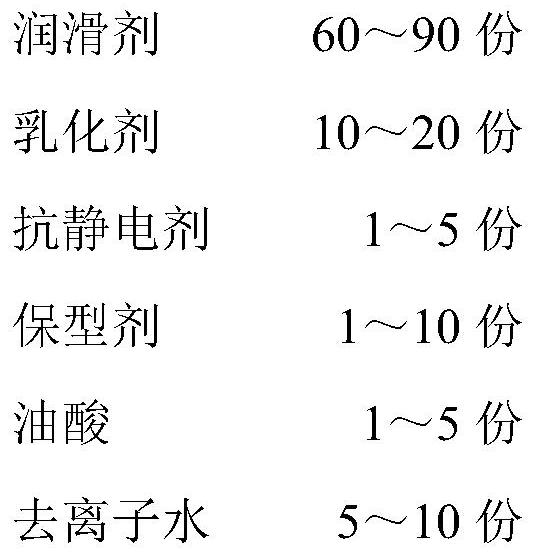

[0022] According to the number of parts by mass, it is composed of:

[0023]

[0024] The fatty alcohol polyether is, the structural formula is C 12 h 25 O(CH 2 CH 2 O) 3 H lauryl ether.

[0025] The fatty acid polyester is, the structural formula is C 12 h 25 COO(CH 2 CH 2 O) 10 H is 5 parts of lauric acid polyester and the structural formula is C 18 h 37 COO(CH 2 CH 2 O) 9 A combination of 5 parts of polyester stearate.

[0026] The fatty amine polyether is, the structural formula is C 12 h 25 N[(CH 2 CH 2 O) 10 H] 2 dodecylamine polyether.

[0027] The oleic acid is vegetable oleic acid with an oleic acid content of 85%.

[0028] (2) Preparation method

[0029] Prepare materials according to the above-mentioned parts by mass, add No. 10 white oil, No. 15 white oil, oleic acid, fatty alcohol polyether, fatty acid polyester, and fatty amine polyether into the compounding kettle A in sequence, and after each addition, the ...

Embodiment 2

[0031] (1) Raw materials

[0032] According to the number of parts by mass, it is composed of:

[0033]

[0034]

[0035] The fatty alcohol polyether is, the structural formula is C 12 h 25 O(CH 2 CH 2 O) 5 H lauryl ether.

[0036] The fatty acid polyester is, the structural formula is C 12 h 25 COO(CH 2 CH 2 O) 10 H is 5 parts of lauric acid polyester and the structural formula is C 18 h 37 COO(CH 2 CH 2 O) 6 A combination of 7 parts of polyester stearate.

[0037] The fatty amine polyether is, the structural formula is C 12 h 25 N[(CH 2 CH 2 O) 10 H] 2 dodecylamine polyether.

[0038] The oleic acid is vegetable oleic acid with an oleic acid content of 85%.

[0039] (2) Preparation method

[0040] Prepare materials according to the above-mentioned mass parts, add No. 10 white oil, No. 15 white oil, oleic acid, fatty alcohol polyether, fatty acid polyester, and fatty amine polyether into the compounding kettle A in sequence, and after each feedin...

Embodiment 3

[0042] (1) Raw materials

[0043]

[0044] The fatty alcohol polyether is, the structural formula is C 18 h 37 O(CH 2 CH 2 O) 10 H's stearyl ether.

[0045] The fatty acid polyester is, the structural formula is C 12 h 25 COO(CH 2 CH 2 O) 15H is 4 parts of lauric polyester and the structural formula is C 18 h 37 COO(CH 2 CH 2 O) 10 A combination of 5 parts of oleic acid polyester.

[0046] The fatty amine polyether is, the structural formula is C 18 h 37 N[(CH 2 CH 2 O) 12 H] 2 octadecylamine polyether.

[0047] The oleic acid is vegetable oleic acid with an oleic acid content of 85%.

[0048] (2) Preparation method

[0049] Prepare materials according to the above-mentioned parts by mass, add No. 10 white oil, No. 15 white oil, glyceryl monostearate, oleic acid, fatty alcohol polyether, fatty acid polyester, and fatty amine polyether into the compounding kettle in sequence In A, stir at room temperature for 10 minutes after each addition; add deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com