Oil pumping device for full-enclosed inverter compressor

A variable frequency compressor, fully enclosed technology, applied in variable capacity pump components, liquid variable capacity machinery, pump components, etc., can solve the problems of inapplicable frequency conversion compressors, etc., to simplify the production process and installation process, and improve reliability High, low oiling resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

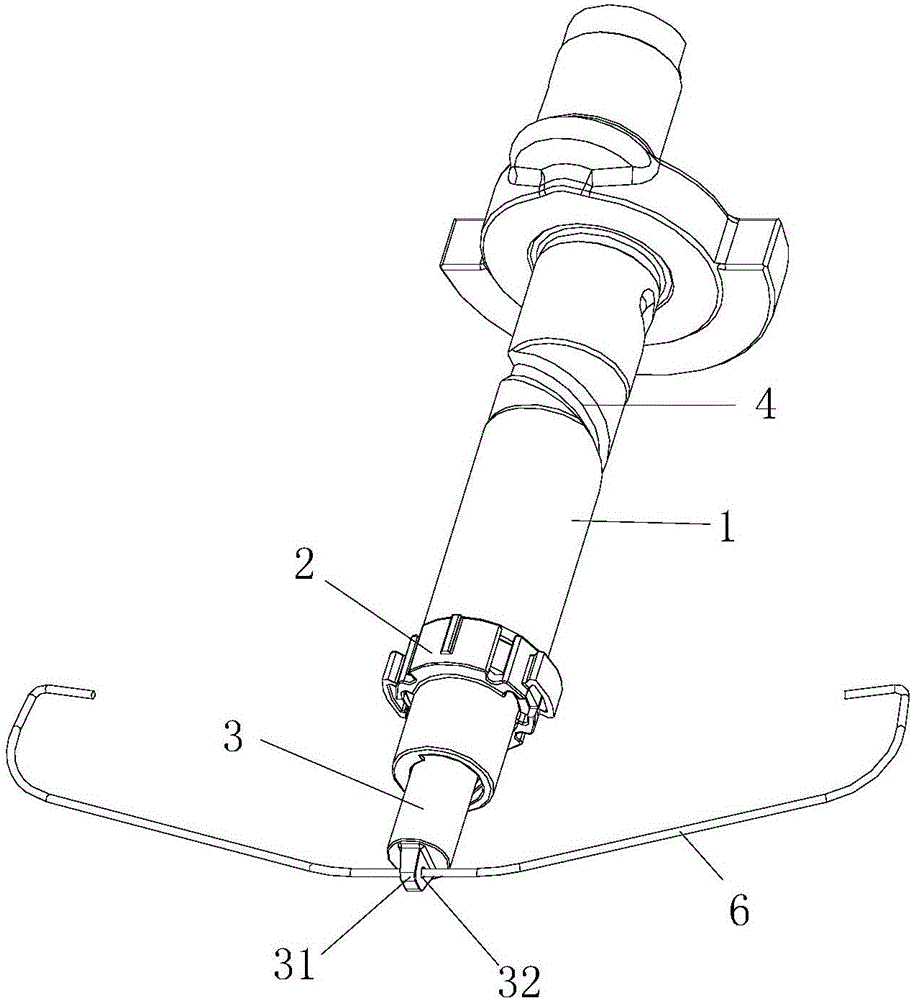

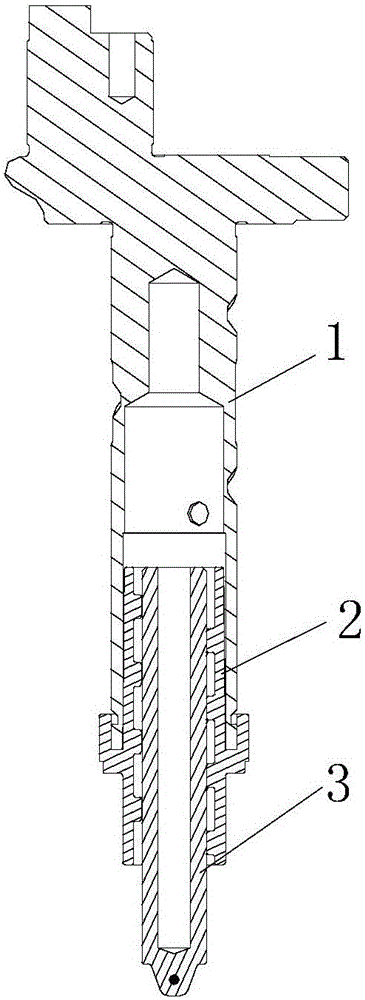

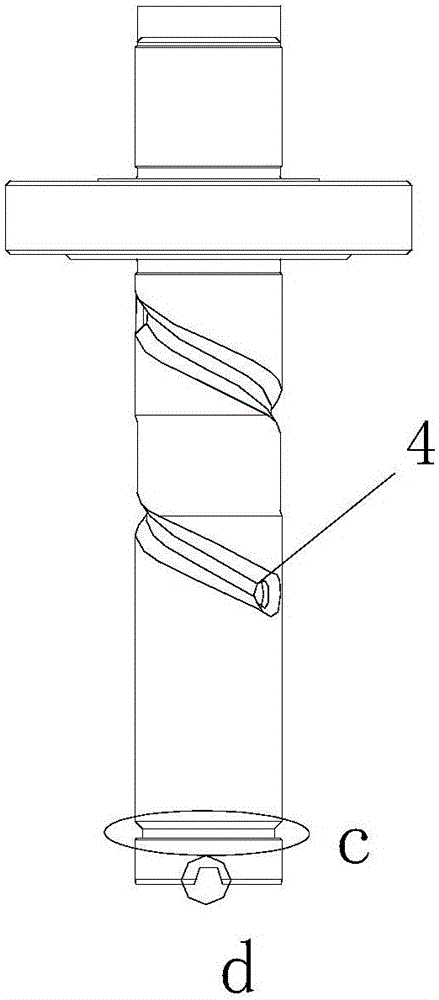

[0031] like Figure 1 to Figure 7 As shown, an oil pumping device for a fully enclosed variable frequency compressor includes a crankshaft 1, an oil suction pipe 2, a stator and a casing for wrapping the crankshaft 1 and the oil suction pipe 2, and the outer cylindrical surface of the crankshaft 1 There is an upper oil tank 4 on it. The oil suction pipe 2 is sleeved on the outer side of the lower part of the crankshaft 1 , and an oil suction pipe core 3 is arranged in the oil suction pipe 2 . Both the oil suction pipe 2 and the oil suction pipe core 3 are made of plastic. The oil suction pipe 2 and the oil suction pipe core 3 are molded at one time by injection molding. The crankshaft 1, the oil suction pipe 2, the oil suction pipe core 3 and the stator are located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com