Fully automatic wax oil mixing and canning machine

A mixing tank and fully automatic technology, which is applied in the manufacture of capacitors, electrical components, capacitors, etc., can solve the problems of inaccurate oil filling and low efficiency, and achieve the effects of simple operation, high work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings:

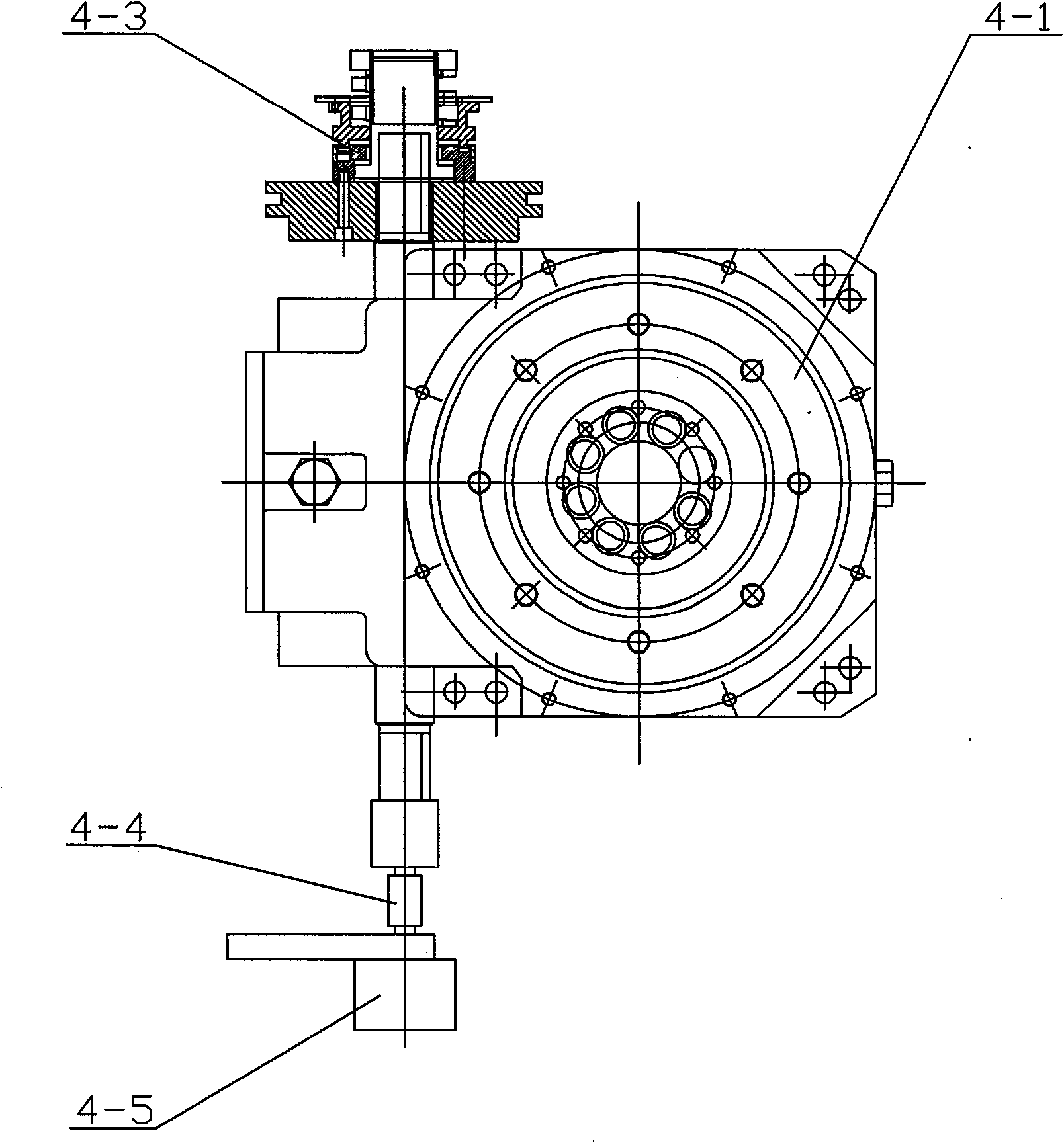

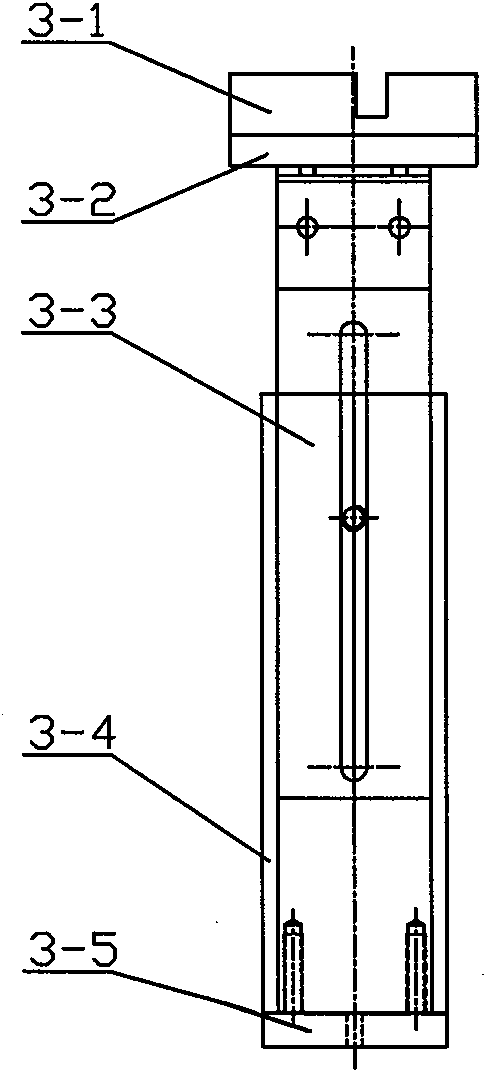

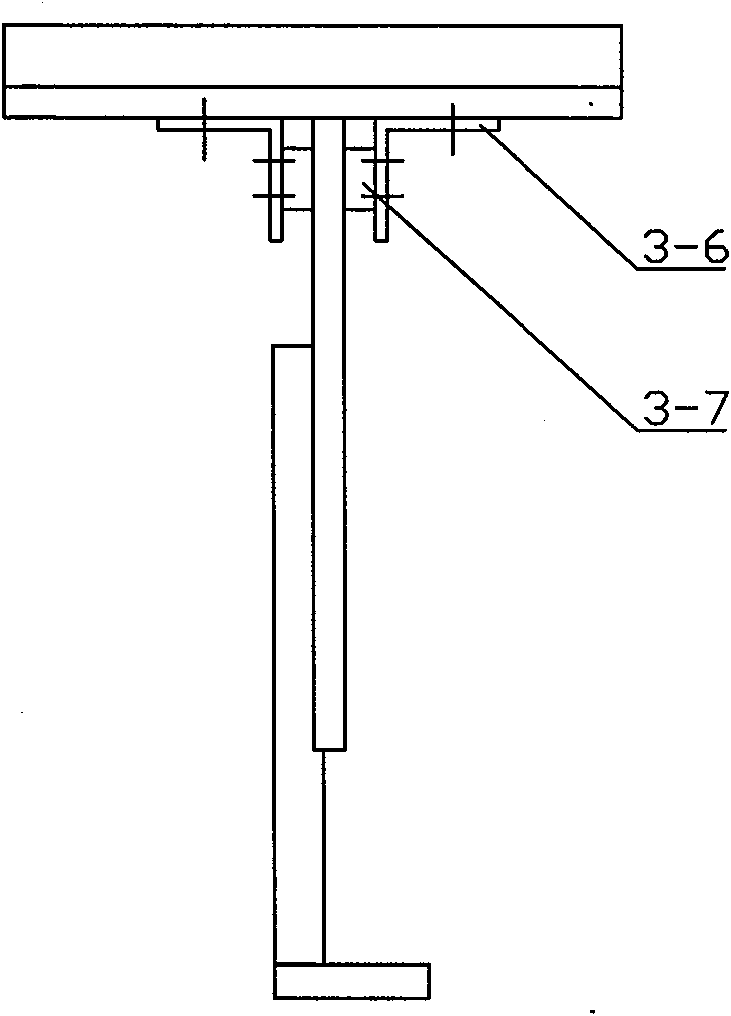

[0025] like Figure 1 to Figure 8 As shown, it includes: anchor bolt 1, bench 2, feeding device 3, indexing mechanism 4, connecting flange 5, oil filling device 6, oil drum 7, round table 8, turntable 9, feeding device 10, motor 11. Gripper 12, first sprocket 13, chain 14, second sprocket 15, energizing overload clutch 16, encoder 17, soft connector 18, fixing block 19, cylinder assembly 20, ball valve 21, oil filler 22 , connecting block 23, limiting member 24, oil pipeline 25, etc.

[0026] like Figure 1 to Figure 4 As shown, the stand 2 of the present invention is fixed on the ground by anchor bolts 1, the motor 11 and the indexing mechanism 4 are respectively fixed on the stand 2 by bolts, the first sprocket 13 is installed on the main shaft of the motor 11, the second The sprocket 15 is installed on the main shaft of the indexing mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com