Rotary compressor

A rotary compressor and compression mechanism technology, applied in the field of compressors, can solve the problems of efficiency performance drop, compressor failure, etc., and achieve the effect of reducing oil volume, reducing failure rate, and ensuring oil volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

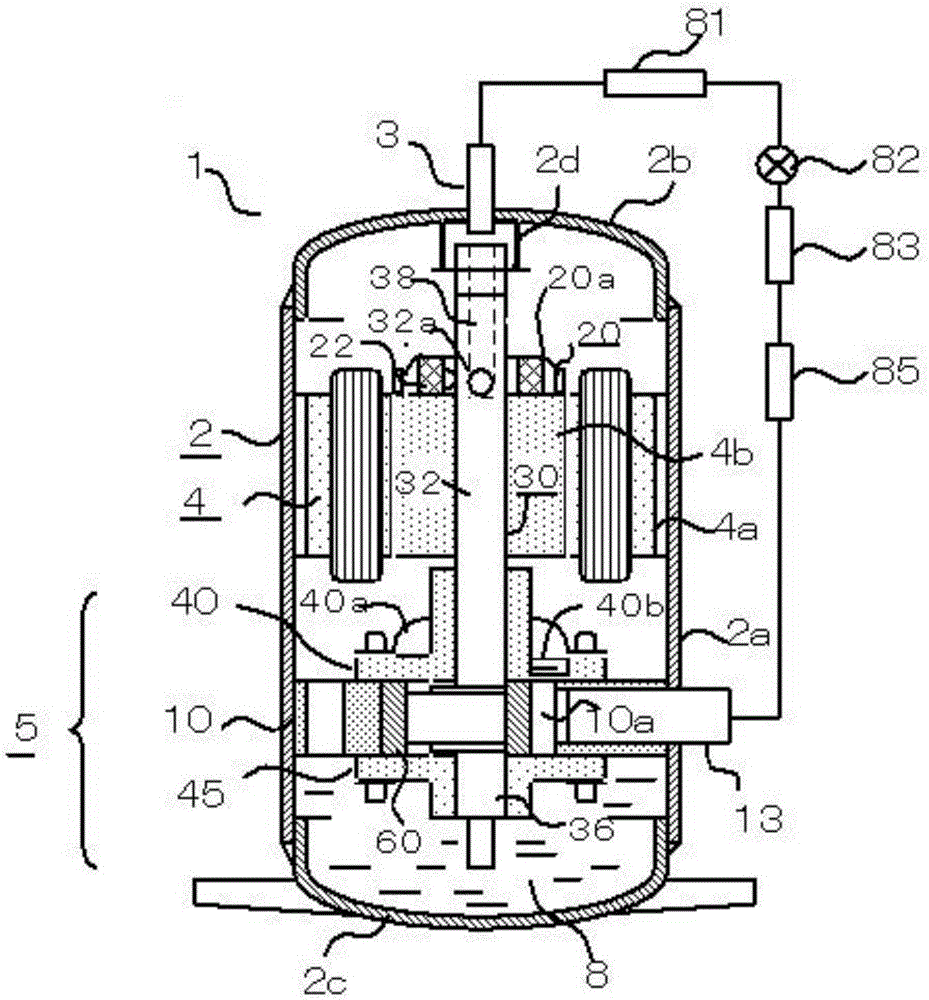

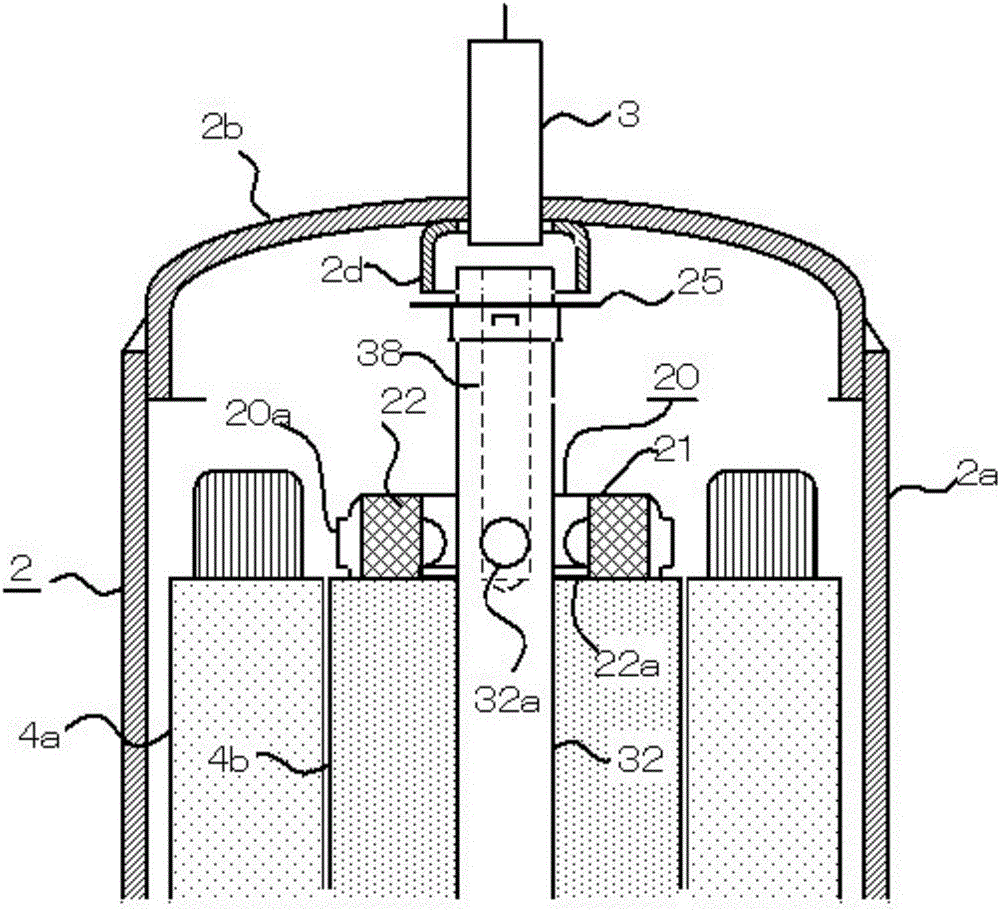

[0036] Such as figure 1 As shown, the rotary compressor 1 accommodates an inverter motor 4 capable of changing the rotation speed and a compression mechanism part 5 in a housing 2, and the outer periphery of the stator 4a constituting the motor 4 and the outer periphery of the cylinder 10 arranged at the center of the compression mechanism part 5 are fixed. On the inner peripheral wall of the housing 2. The casing 2 is composed of a cylindrical casing 2a, an upper end plate 2b and a lower end plate 2c welded to its upper and lower ends. In addition, the bottom of the casing 2 is provided with an oil storage tank 8 for storing oil.

[0037] The compression mechanism unit 5 includes a piston 60 housed in the compression chamber 10 a of the cylinder 10 , a slide plate (not shown) reciprocating together with the piston, a main bearing 40 and a sub bearing 45 arranged on the cylinder, and a crankshaft 30 . Crankshaft 30 includes main shaft 32 and counter shaft 36 in sliding engag...

Embodiment 2

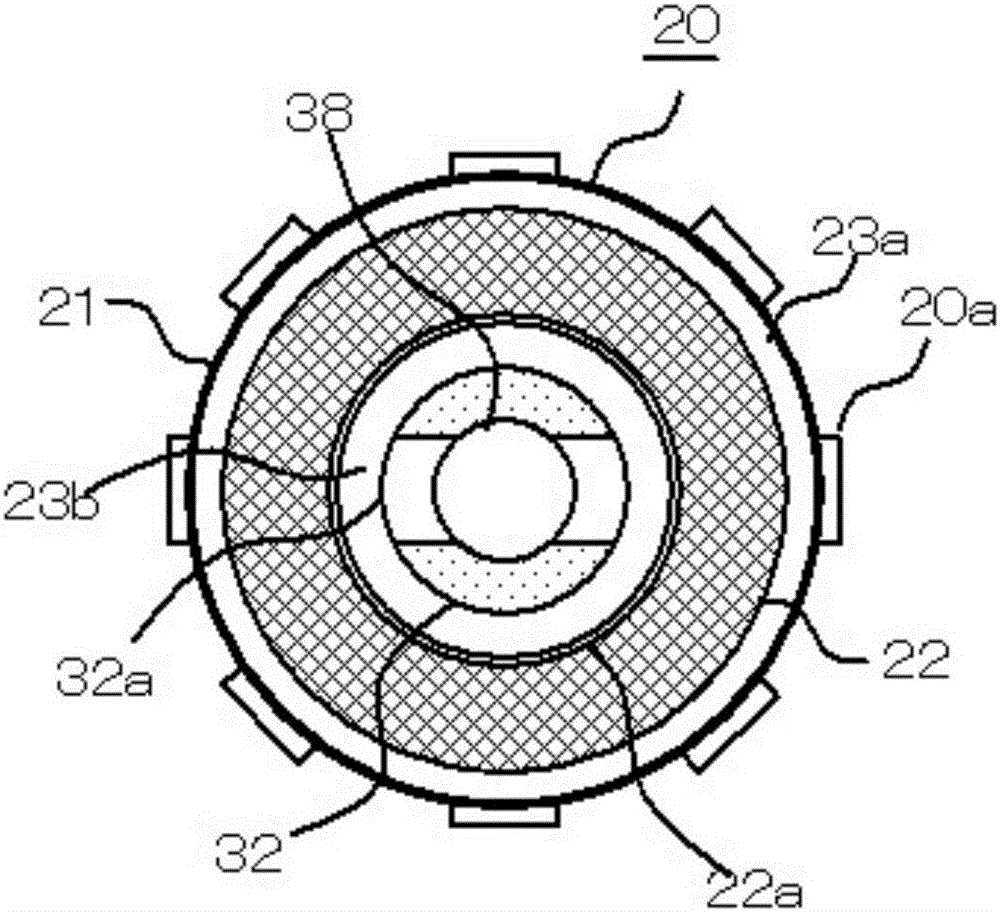

[0047] Figure 4 In the oil separator 20 shown, the cylindrical case 21 used in the first embodiment is omitted. Through the top plate 27 and the rivets 28, the oil filter 22 is fixed directly to the rotor 4b. Furthermore, the inlet of the exhaust pipe 3 is opened at the center of the oil separator 22 .

[0048] Compared with Example 1, Example 2 does not need to change the design of the crankshaft 30, and it is easy to use the oil separator 20. Furthermore, the functions of the oil separator 20 are basically the same. Also, if necessary, append figure 2 filter box 22a.

[0049] The multi-cylinder rotary compressor of the present invention can be mounted on an air conditioner, a refrigeration device, a water heater, a vehicle-mounted refrigeration system, a vehicle-mounted air conditioner, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com