Automatic conveying belt cleaning device

An automatic cleaning and conveyor belt technology, applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve problems such as increased labor intensity and safety hazards, insignificant cleaning effect, conveyor belt damage, etc., to improve production efficiency. and customer satisfaction, improving product surface quality and reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

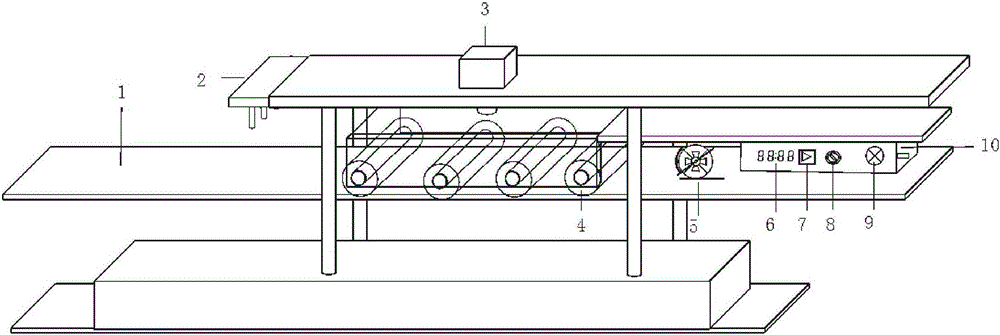

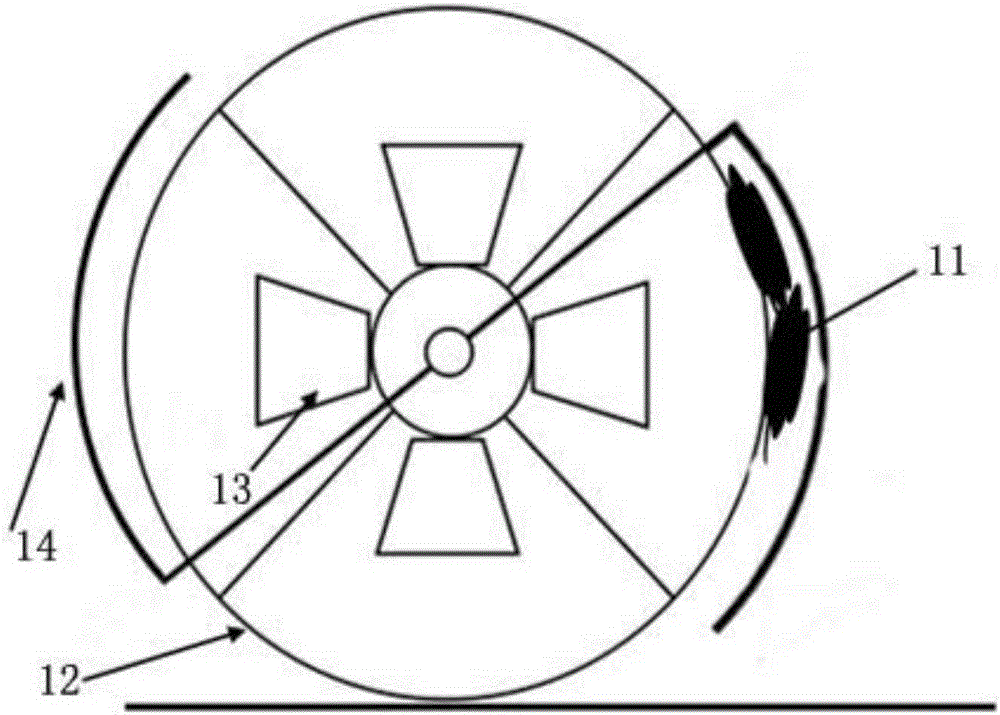

[0020] Such as figure 1 As shown, a conveyor belt automatic cleaning device includes a conveyor belt 1, an oil rubbing roller 4 and a cylinder 3, the cylinder 3 is connected with the oil rubbing roller 4 through a control rod, and the cylinder 3 can automatically rise and fall to rub the oil Roller 4, when the control rod rises, the oil rubbing roller 4 is separated from the conveyor belt 1, and the cleaning operation stops. The conveyor belt 1 is provided with an oil pollution sensor 5 , and the cylinder 3 and the oil pollution sensor 5 are respectively connected with a controller 10 . The top of the conveyer belt 1 is provided with an air injection port, and several air nozzles 2 can be installed in the air injection port, and the air injection can be performed while the wiping operation is carried out, which can improve the efficiency of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com