Noise reduction type oil-gas separation device for hydraulic retarder

A technology of hydraulic retarder and separation device, applied in the direction of hydraulic resistance brake, brake type, mechanical equipment, etc., can solve the problems of affecting the braking performance of hydraulic retarder, reducing driving safety, lack of working oil, etc. , to achieve the effect of simple structure, continuous and stable braking performance, and prevention of oil leakage and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

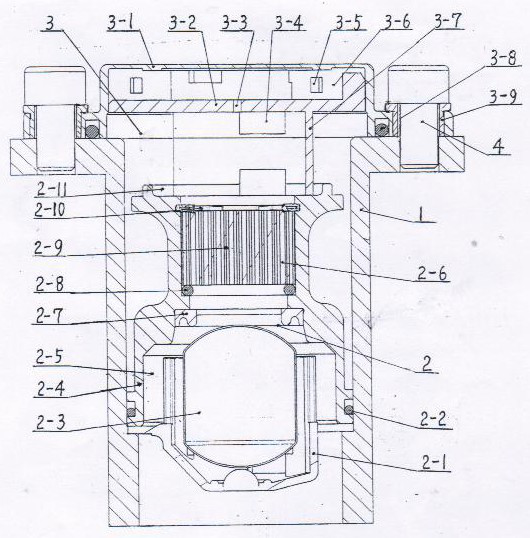

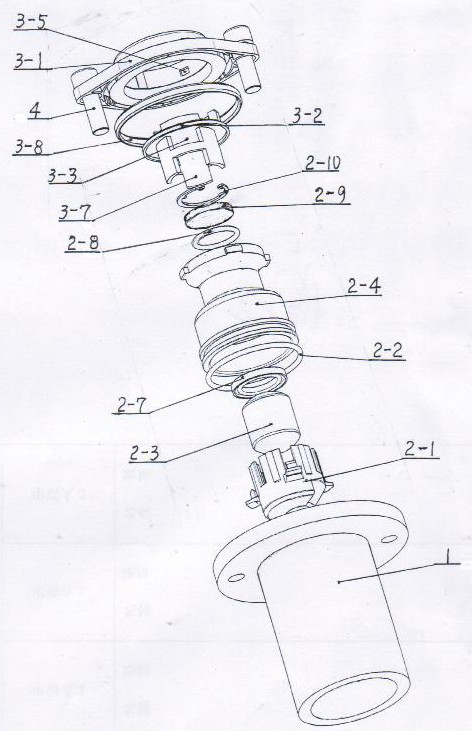

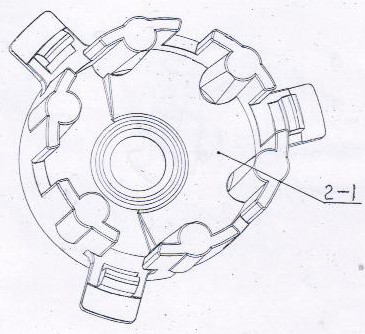

[0012] Examples, see attached Figure 1-4 , The noise-reducing oil-gas separation device for the hydraulic retarder is composed of the middle cover 1, the oil-gas separation assembly 2, and the dust cover assembly 3. The oil-gas separation assembly 2 consists of an oil-gas separation lower cover 2-1, an O-ring 2-2, a floating ball 2-3, an oil-gas separation body 2-4, an oil-resistance chamber 2-5, an oil-gas separation chamber 2-6, a sealing Pad 2-7, O-ring 2 2-8, oil-gas separation plate 2-9, circlip 2-10, oil return tank 2-11, dust cover assembly 3 consists of dust cover 3-1, partition 3-2, ventilation hole 3-3, oil return chamber 3-4, intake and exhaust holes 3-5, intake and exhaust chamber 3-6, partition bracket 3-7, O-ring three 3-8, metal hole Sets of 3-9 compositions. The oil and gas separation lower cover 2-1 of the oil and gas separation assembly 2 is placed in the inner cavity of the middle cover 1, the umbrella edge of the oil and gas separation lower cover 2-1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com