Crankcase ventilation system and gas engine

A crankcase ventilation and crankcase technology, which is applied to crankcase ventilation, engine components, machines/engines, etc., can solve the problems of inability to effectively control crankcase pressure, deterioration of emissions, and large loss of oil volume, and to ensure normal oil volume. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

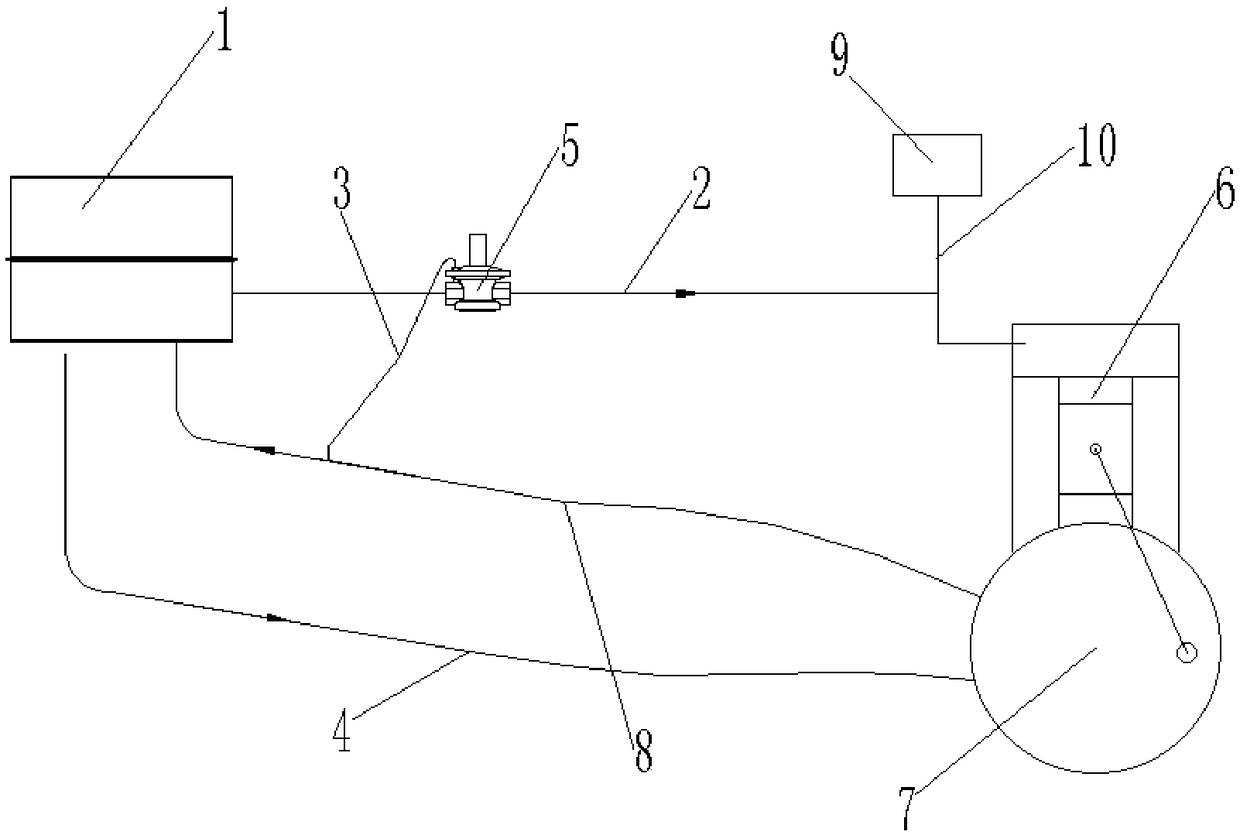

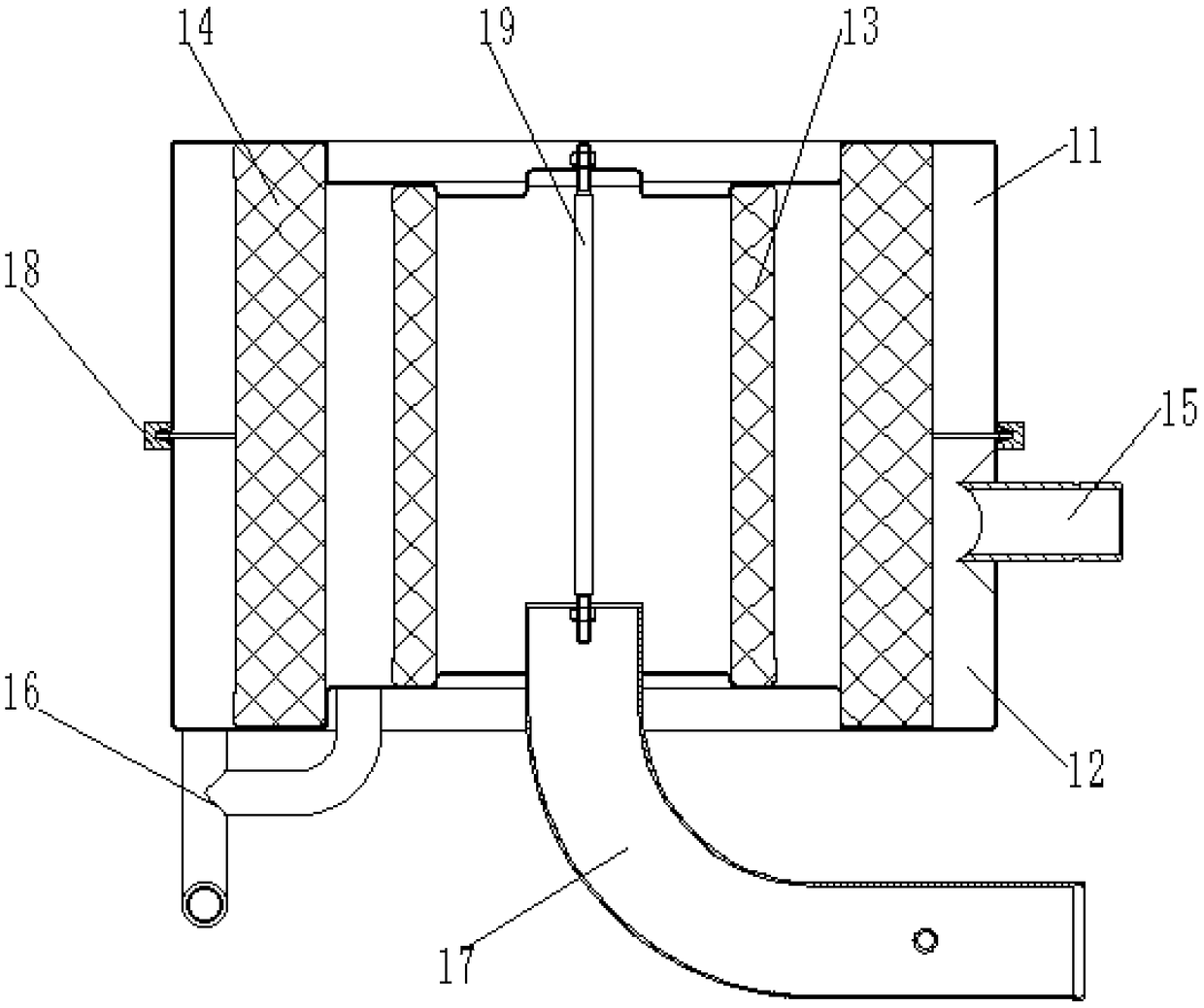

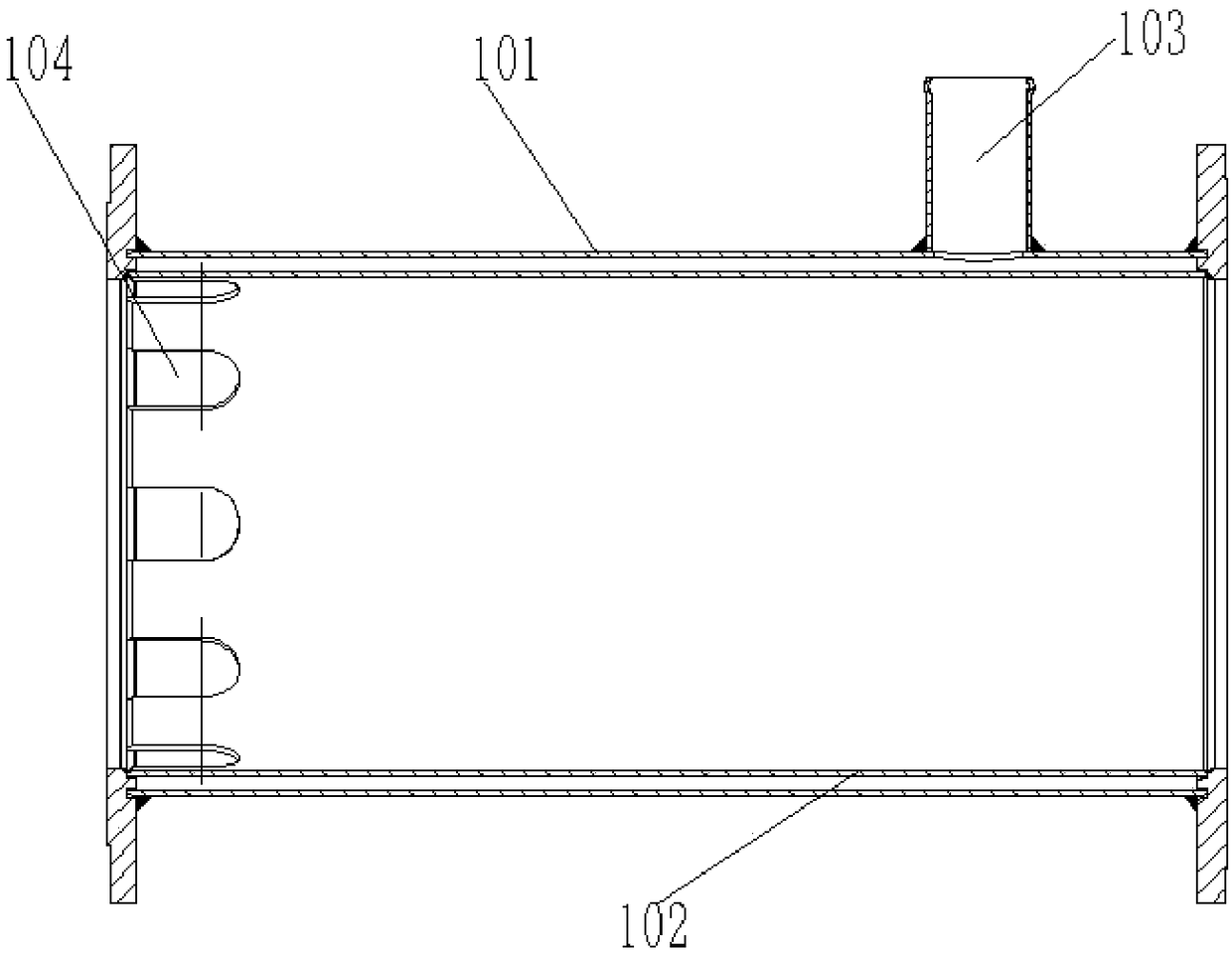

[0033] Such as figure 1 - image 3 As shown, the embodiment of the present invention provides a crankcase 7 ventilation system, including an oil-gas separator 1, an air return pipe 2, a balance pipe 3, an oil return pipe 4, a pressure regulating valve 5, an internal combustion engine 6, a crankcase 7 and a ventilation pipe 8; The crankcase 7 is communicated with the oil-gas separator 1 through the ventilation pipe 8, and the oil-gas mixture in the crankcase 7 can be passed into the oil-gas separator 1, and the oil-gas separator 1 case is communicated with the crankcase 7 through the oil return pipe 4, and the separated The oil is passed into the oil-gas separator 1, and the tank of the oil-gas separator 1 communicates with the internal combustion engine 6 through the air return pipe 2, and the separated mixed gas can be passed into the internal combustion engine 6; the pressure regulating valve 5 is connected in series with the air return pipe 2, and the crankcase 7 is balance...

Embodiment 2

[0057] An embodiment of the present invention provides a gas engine, including the crankcase 7 ventilation system as described above.

[0058] In the gas engine provided by the embodiment of the present invention, by adopting the crankcase 7 ventilation system of the above-mentioned embodiment, the combustible mixed gas filtered by the oil-gas separator 1 is passed through the return pipe 2 into the combustion chamber of the internal combustion engine 6 for secondary combustion, reducing the pollution of the environment. Simultaneously, the engine oil filtered out by the oil-air mixture in the oil-air separator 1 will flow into the crankcase 7 again through the oil return pipe 4, so as to ensure the normal amount of oil in the crankcase 7. Finally, by connecting the pressure regulating valve 5 in series on the air return pipe 2, and making the crankcase 7 communicate with the diaphragm upper chamber of the pressure regulating valve 5 through the balance pipe 3, the pressure in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com