Axle shaft for automobile drive axle

A technology for driving axles and vehicles, which is applied to axles, shafts, wheels, etc. It can solve the problems of poor heat dissipation of wheel-end mechanisms, high-temperature oil and gas, many faults of wheel-end mechanisms, and short service life, achieving good cooling effect and low cost , making convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

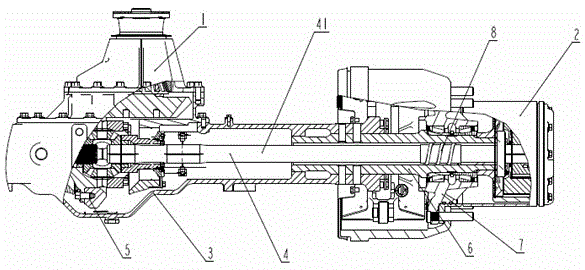

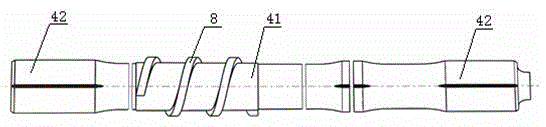

[0035] see figure 1 , image 3 , the drive axle half shaft for a vehicle of the present invention is also called the half shaft for a wheel-side reduction axle, and includes a shaft body 41 and splines 42 located at both ends of the shaft body. The outer circular surface of the shaft body 41 is provided There is a helical structure 8, and the direction of rotation of the helical structure 8 is determined by the rotation direction when the shaft body 41 drives the driving axle and the vehicle forward and the direction of the fluid in the helical structure 8 flowing to the final drive side according to the left and right hand rules . That is, the direction of rotation of the helical structure 8 is determined by the direction of rotation of the axle shaft 4 and the direction in which the helical structure delivers lubricating oil when the wheel on the drive axle rotates forward. as in image 3 Among them, the half shaft 4 on the right side of the final drive 1 is the right ha...

Embodiment 2

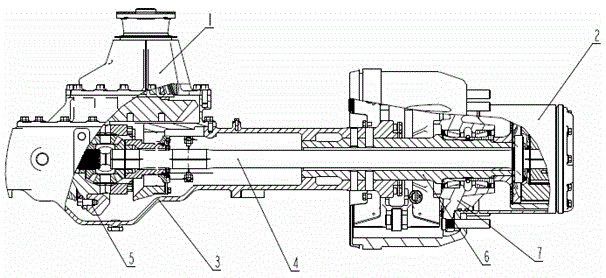

[0047] see figure 2 , image 3 , the vehicle drive axle half shaft is a semi-floating half shaft 4 on the right side of the oil-lubricated drive axle, and the half shaft 4 includes a shaft body 41, a key joint at one end of the shaft body and a flange 43 at the other end of the shaft body , the key connection part is a spline, and a helical structure 8 is provided on the outer surface of the shaft body 41. The double-headed spiral rib on the outer surface, the spiral rib is set on the side near the wheel end in the middle of the half shaft 4, and the spiral rib is fixed on the outer surface of the shaft body 41 by bonding Copper metal wire, the diameter of the wire, that is, the height of the spiral rib is 2 mm, generally controlled below 4 mm, and the cross-sectional shape of the spiral rib is circular, or rectangular, conical. shape, trapezoid or semicircle. Other structures of this embodiment are basically the same as those of Embodiment 1.

Embodiment 3

[0049] see figure 1 , image 3 , the vehicle drive axle half shaft is the full floating half shaft 4 on the right side of the wheel reduction axle, including the shaft body 41 and the splines 42 located at both ends of the shaft body 41, which are arranged on the outer circular surface of the shaft body 41 A helical structure 8 is provided, the direction of rotation of the helical structure 8 is left-handed, and the helical structure 8 is a single-headed helical groove hovering on the outer surface of the shaft body 41, and the helical groove is arranged on the half shaft At the corresponding length position of the shaft body 41 on the shaft tube 6 and the shaft tube 6, the cross-sectional shape of the spiral groove is a semicircular groove, or a rectangular groove, a tapered groove or a trapezoidal groove.

[0050] The depth of the spiral groove is about 1-4 mm, generally controlled below 4 mm, and it should be ensured that the maximum outer diameter of the spiral groove is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com