Lubricating device of head stock in universal machine tool

A technology of lubricating device and general machine tool, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. Reasonable structure design, saving processing cost and improving utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

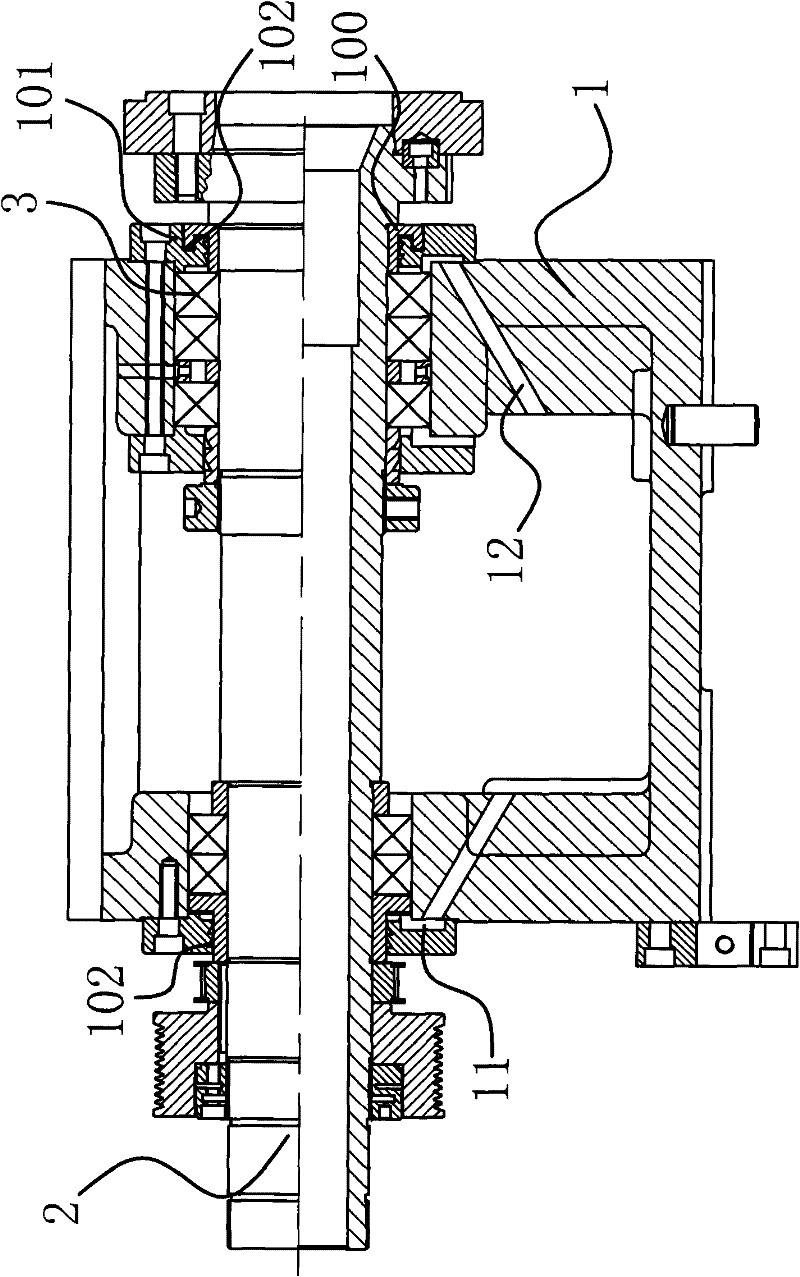

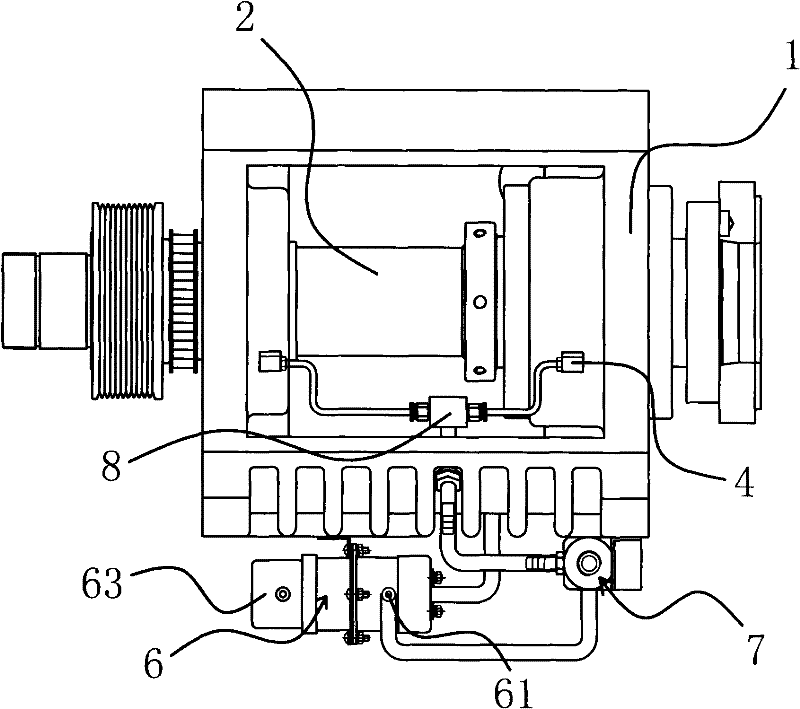

[0036] Such as figure 1 with figure 2 As shown, the headbox in a general-purpose machine tool includes a box body 1, a drive shaft 2 axially fixed on the box body 1 and capable of rotating in the circumferential direction, and 5 bearings 3 between the box body 1 and the drive shaft 2. The drive shaft 2 Wear in the box 1, such as Figure 5 As shown, two bearings 3 are installed at one contact point of the transmission shaft 2 and the box body 1, and three bearings 3 are installed at the other contact point, and the transmission shaft 2 is inserted in the bearing 3.

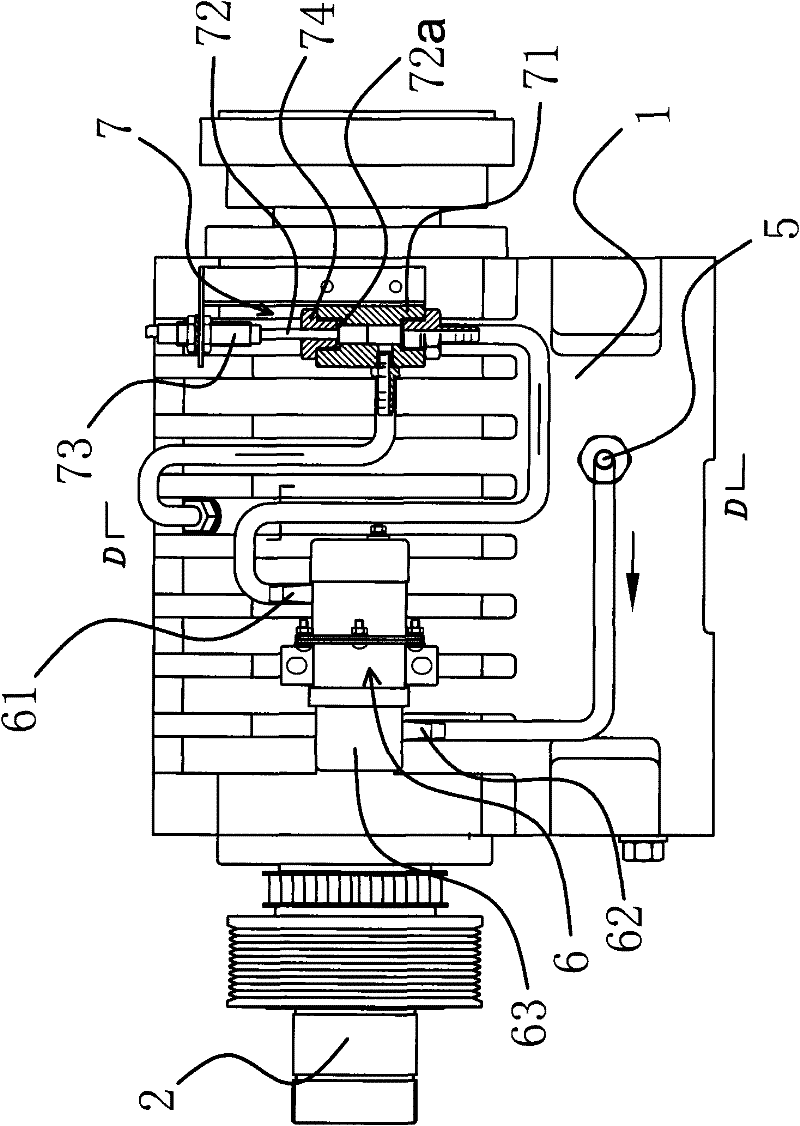

[0037] Such as image 3 As shown, the lubrication device is arranged on the box body 1, and includes a lubrication pump 63 with an oil supply port 61 and an oil return port 62 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com