Eccentrically-adjusted variable rotor oil pump

A rotor oil pump and variable variable technology, which is applied in the direction of lubricating pumps, mechanical equipment, engine components, etc., can solve the problems of reducing engine economy and increasing engine power loss, and achieves the effects of simple structure, improved safety, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

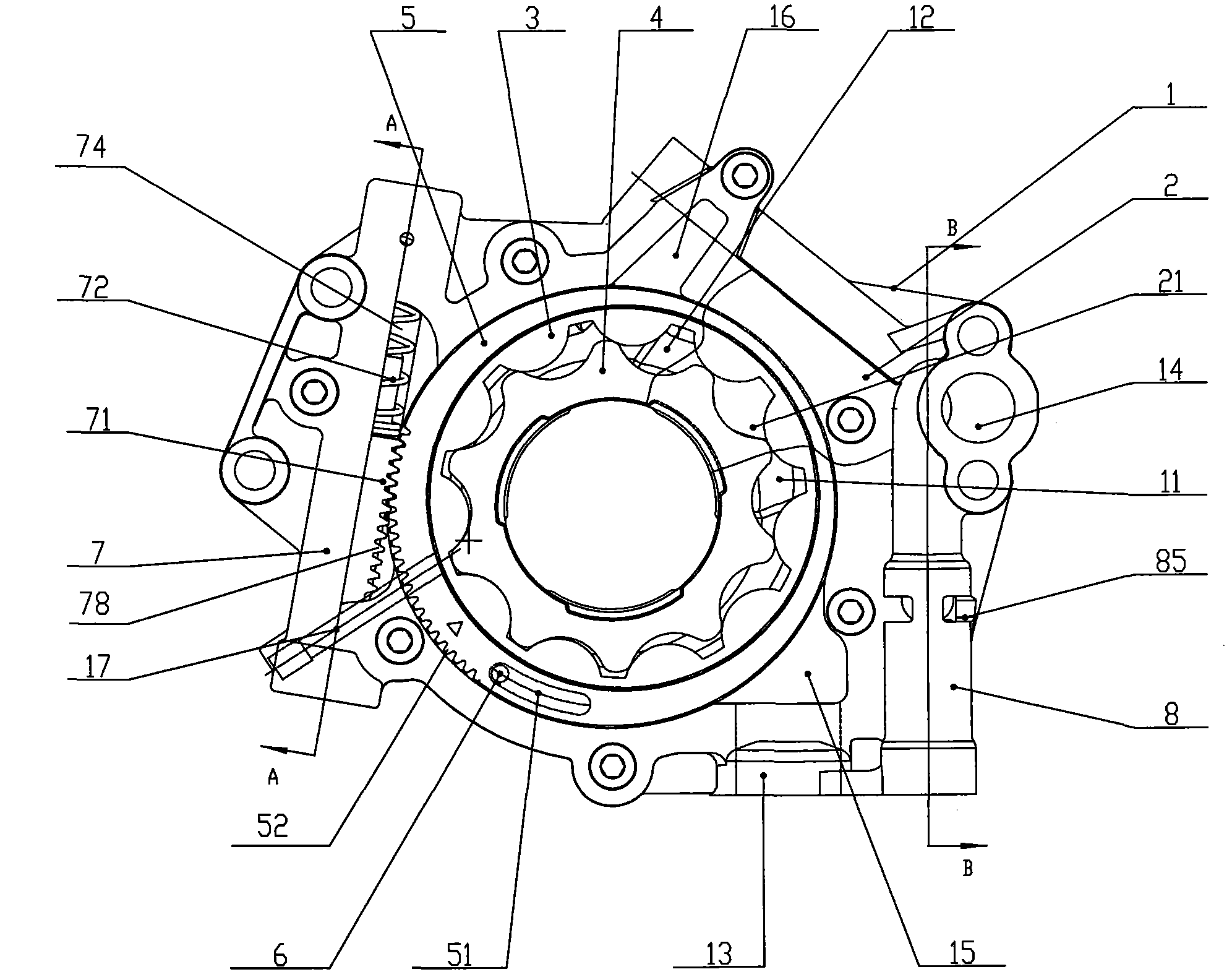

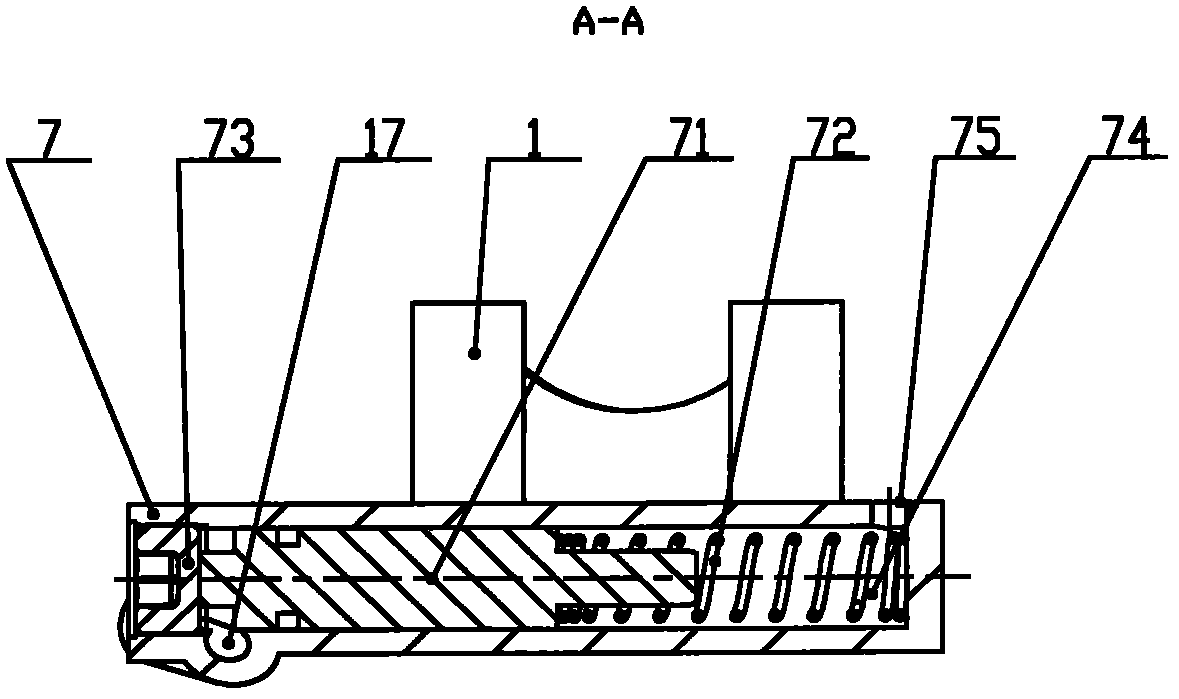

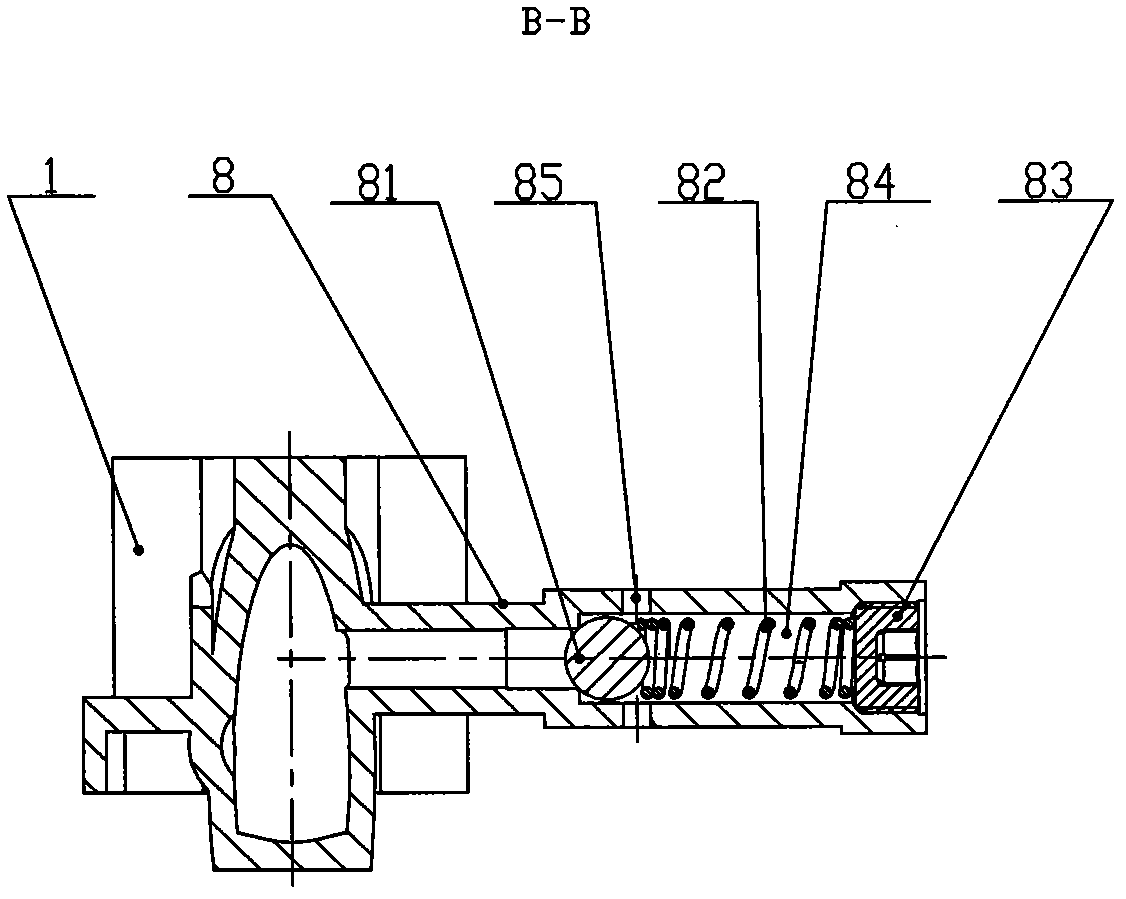

[0018] An eccentrically regulated variable rotor oil pump is composed of a pump body 1 , a pump cover 2 , an outer rotor 3 , an inner rotor 4 , an eccentric ring with outer teeth 5 , a retaining pin 6 , a rack valve part 7 and a safety valve part 8 . An oil inlet chamber 11 and an oil outlet chamber 12 as well as an oil inlet 13 and an oil outlet 14 are arranged on the inner side and the bottom surface of the pump body 1, the oil inlet chamber 11 communicates with the oil inlet 13, and the oil outlet chamber 12 communicates with the oil outlet 14 , the oil inlet chamber 11 and the oil outlet chamber 12 are distributed on both sides of the rotor bottom surface and the outside, the oil inlet 13 communicates with the oil absorber, and the oil outlet 14 communicates with the oil passage of the engine. An oil inlet passage 15 and an oil outlet passage 16 are arranged in the pump body 1 , the oil inlet passage 15 communicates with the oil inlet 13 , and the oil outlet passage 16 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com