Oil supply device

An oil supply device and oil supply technology, applied in the direction of power device, control device, transmission device control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

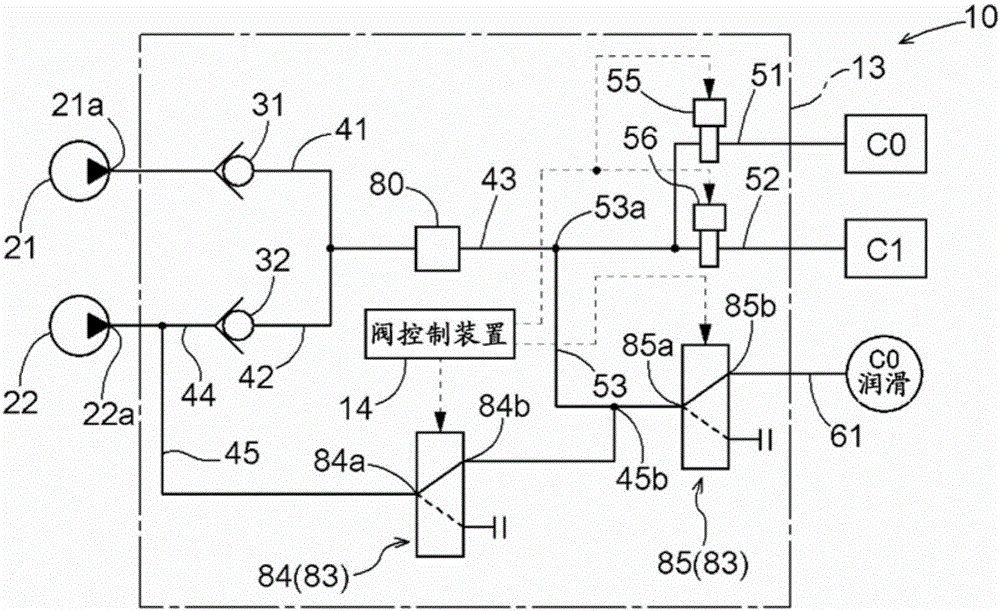

[0042] refer to Figure 1 ~ Figure 4 , the first embodiment of the oil supply device of the present invention will be described.

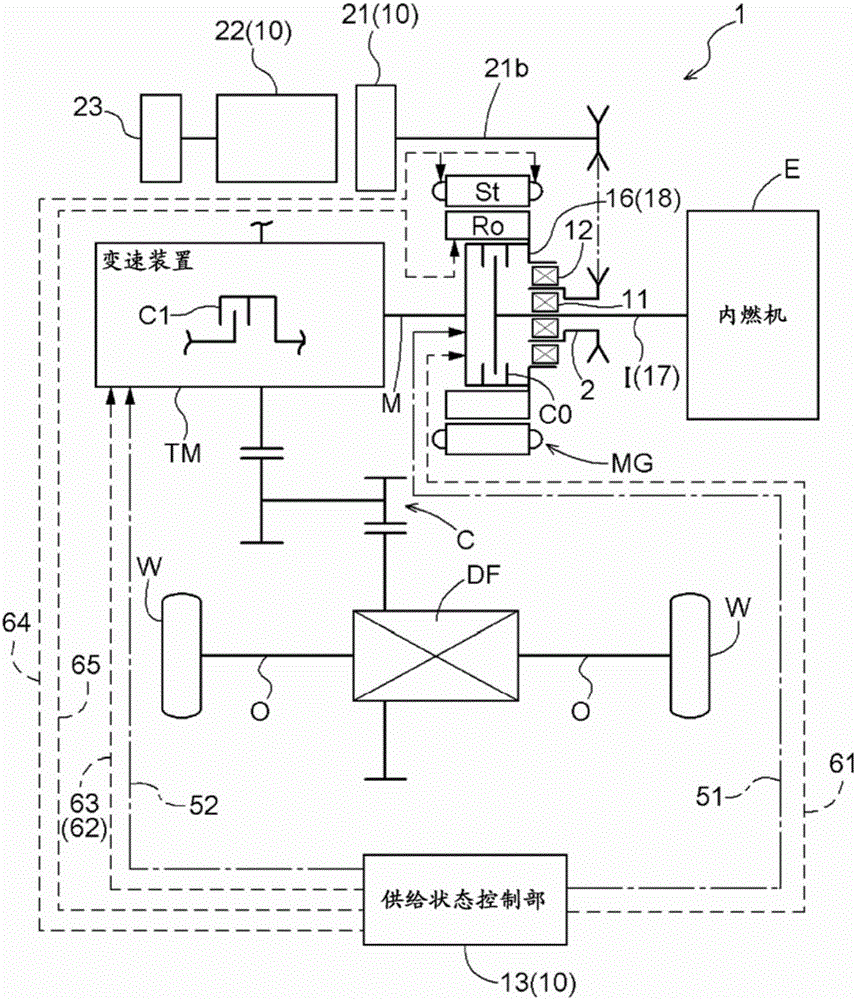

[0043] 1-1. The overall structure of the vehicle drive unit

[0044] First, the structure of the vehicle drive device 1 which is the fuel supply target of the fuel supply device 10 according to the present embodiment will be described. Such as figure 1 As shown, the vehicle driving device 1 of the present embodiment includes an input shaft I drivingly connected to the internal combustion engine E, an output shaft O drivingly connected to the wheels W, an engagement device C0 for disengagement, a rotary electric machine MG for driving the wheels, and a transmission device TM. , gear mechanism C and differential gear device DF. The disengagement engagement device C0, the rotary electric machine MG, the transmission device TM, the gear mechanism C, and the differential gear unit DF are provided on a transmission path connecting the input shaft I an...

no. 2 approach

[0088] refer to Figure 5 A second embodiment of the oil supply device of the present invention will be described. In this embodiment, the point that the supply state control part 13 is equipped with the lubricating branch oil passage 53 is different from the said 1st Embodiment. Hereinafter, differences from the above-mentioned first embodiment will be mainly described, and points not particularly indicated are the same as those of the above-mentioned first embodiment.

[0089] Such as Figure 5As shown, in the present embodiment, the branch oil passage 45 is connected to the first lubricating oil passage 61 without passing through the oil passage downstream of the second check valve 32 (for example, the confluence oil passage 43 ). Furthermore, in the present embodiment, the communication state control valve 83 performs control to switch between a state in which the branch oil passage 45 communicates with the first lubricating oil passage 61 and a state in which the branch...

no. 3 approach

[0093] refer to Figure 6 A third embodiment of the oil supply device of the present invention will be described. In the above-mentioned first and second embodiments, basically only the disengagement engagement device C0 is assumed to be in the slip engagement state, but in this embodiment, the vehicle drive device 1 can be configured to disengage the disengagement engagement device C0 according to the situation. One or both of the device C0 and the transmission engagement device C1 are controlled to be in a slip engagement state and transmit the rotation of the input shaft I to the output shaft O. Therefore, the lubricating device 10 of the present embodiment can be configured to supply a sufficient amount of lubricating oil to both the disengagement engagement device C0 and the transmission engagement device C1 . In addition, in the first embodiment described above, the branch oil passage 45 is configured to be connected to the first lubricating oil passage 61 via the lubri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com