Compressor crankshaft connecting rod oil supply mechanism and compressor

A compressor crankshaft and connecting rod technology, applied in the field of air compressors, can solve the problems of increased oil discharge and unfavorable friction pair oil film, etc., and achieve the effects of improving oil discharge atomization, optimizing oil supply path, and increasing high-frequency cooling capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

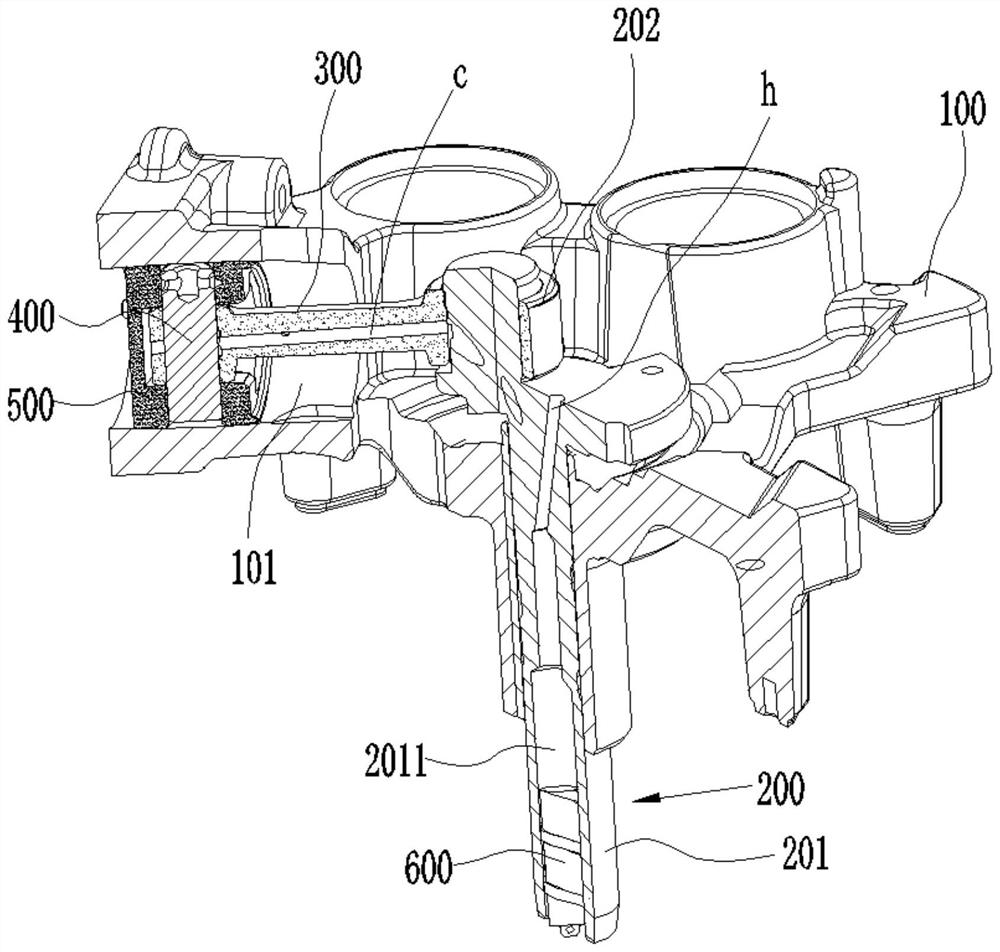

[0037] In this embodiment, a compressor crankshaft connecting rod oil supply mechanism is provided, refer to Figure 1-Figure 3 ,

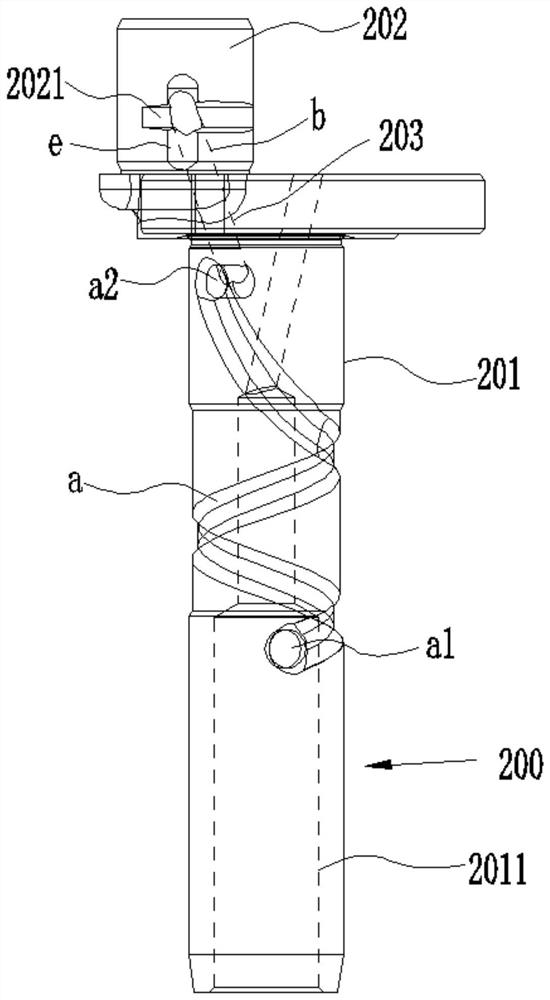

[0038] It includes: a base 100 with a cylinder bore 101 and a shaft hole; a crankshaft 200 , the long axis 201 of the crankshaft 200 is rotatably arranged on the shaft hole of the base 100 ;

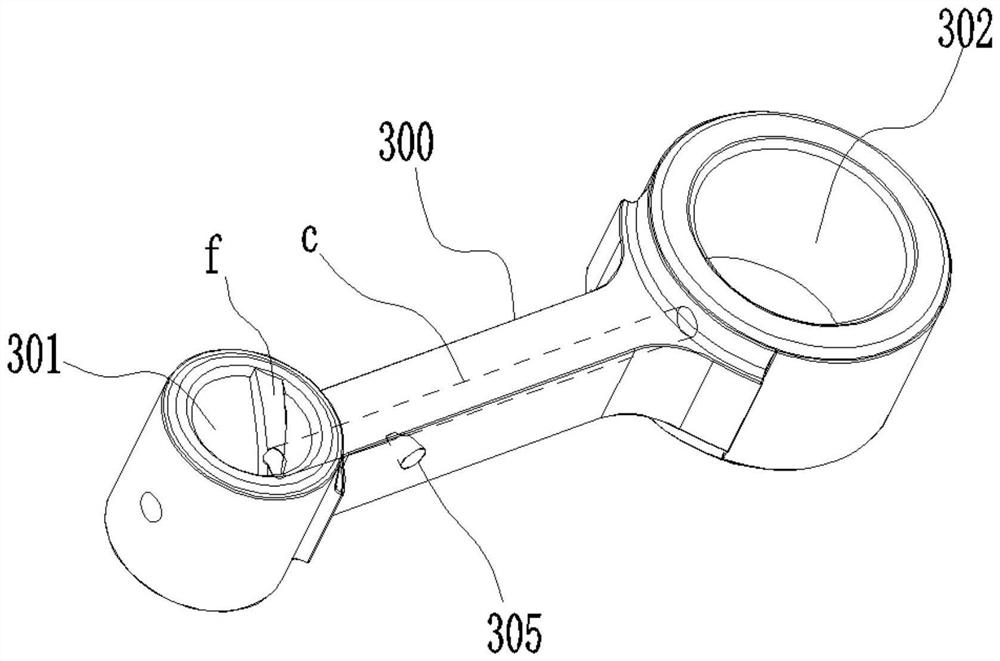

[0039] Connecting rod 300, the two ends of connecting rod 300 are respectively provided with pin shaft hole 301 and crankshaft hole 302, and the minor axis 202 of described crankshaft 200 is connected with described crankshaft hole 302; Piston 400; In the cylinder hole 101, the piston 400 is fixed with a pin shaft 500, and the pin shaft 500 is rotatably connected with the pin shaft hole 301;

[0040]The first mating surface between the long shaft 201 and the shaft hole is provided with a first oil passage a having an oil supply inlet and an oil supply outlet, and a first oil passage a is provided between the short shaft 201 and the long shaft 201. Two oil ...

Embodiment 2

[0064] The second aspect of the present invention discloses a compressor, which includes the compressor crankshaft connecting rod oil supply mechanism described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com