A rotary compressor with an oil storage chamber pump body

A technology of rotary compressor and oil storage chamber, applied in the field of rotary compressors, can solve the problems of increased wear of the pump body, small force area, easy to be affected, etc. The effect of performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

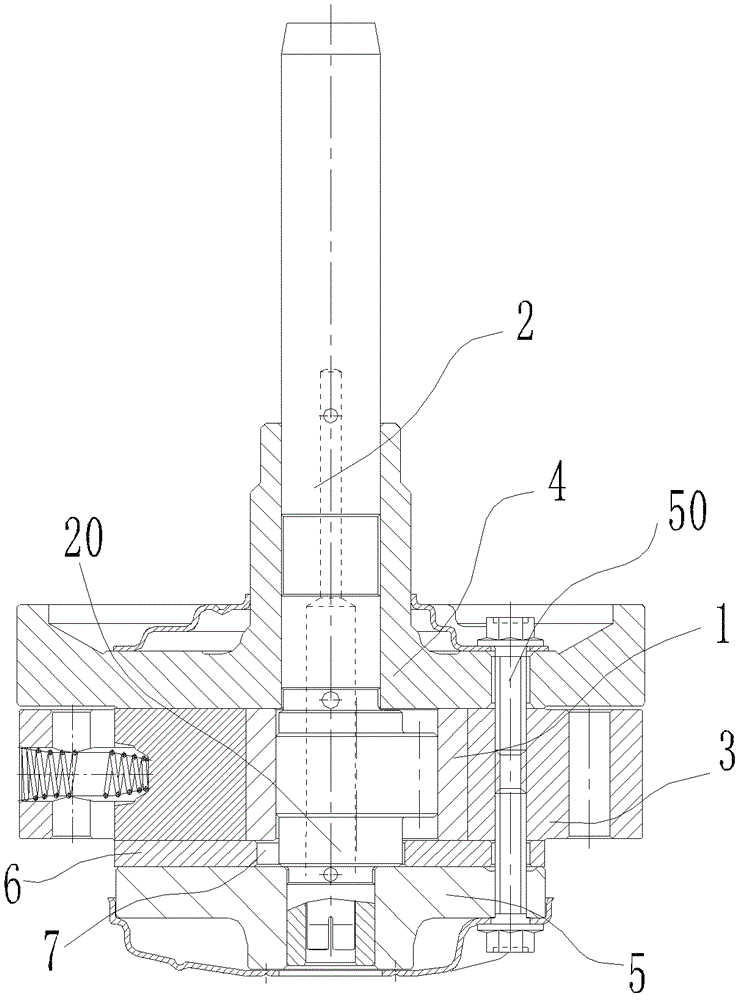

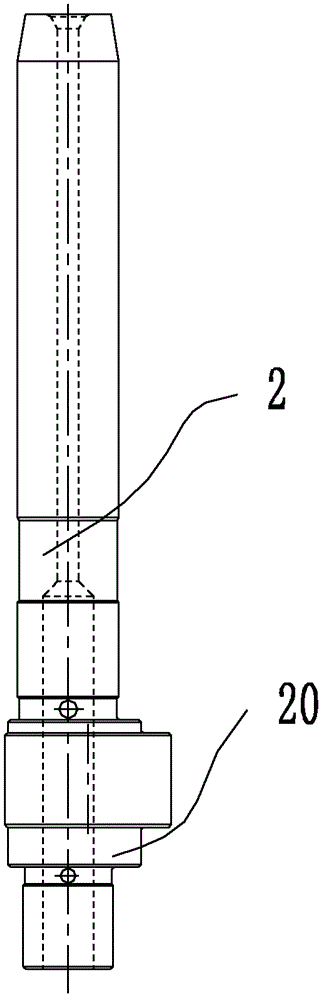

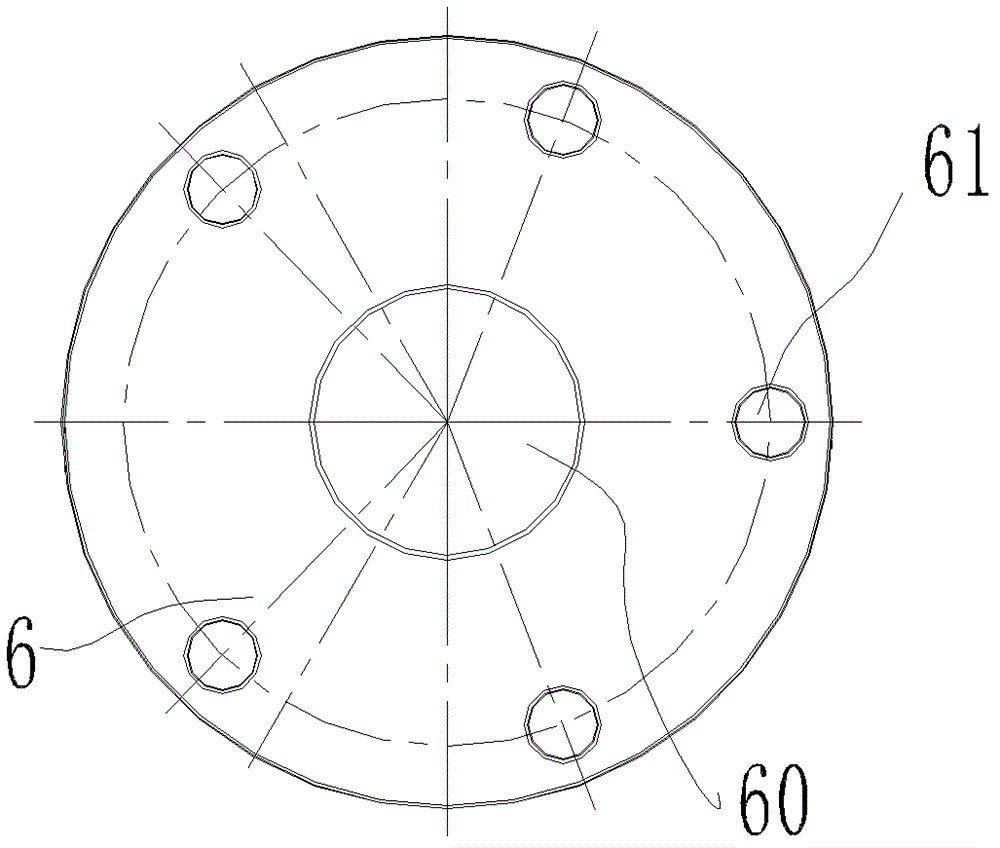

[0019] Such as Figure 1 to Figure 7 As shown, a rotary compressor with an oil storage chamber pump body, the rotary compressor includes a roller 1, a crankshaft 2, a cylinder 3, an upper flange 4 and a lower flange 5, the roller 1 is installed on the crankshaft 2 and It is eccentrically matched with the cylinder 3; the thrust surface at the lower end of the crankshaft 2 extends axially to form a thrust surface extension 20, and a partition plate 6 matching the thrust surface extension 20 is provided between the cylinder 3 and the lower flange 5, The lower flange 5, the short shaft of the crankshaft 2 and the spacer 6 cooperate to form an oil storage chamber 7 that is convenient for lubrication and prevents excess refrigeration oil from being discharged or squeezed out of the exhaust port of the pump body; among them, the thrust surface at the lower end of the crankshaft 2 The friction working surface cooperates with the upper end surface of the lower flange 5, and the frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com