Marine oil water separator

An oil-water separator and marine technology, which is applied in the field of marine machinery and equipment, can solve the problems such as the difficulty of judging and controlling whether the oil discharge is up to standard, the low automation ability of the separation device, and the difficulty in reaching the standard of sewage oil content, etc., and achieves compact structure, The size is reduced to solve the effect of narrowing the installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

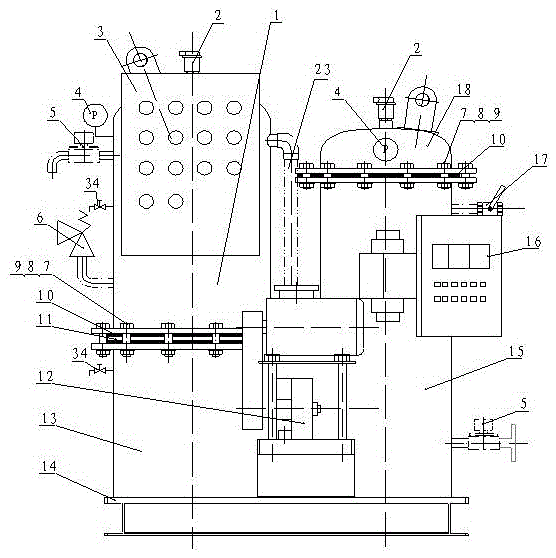

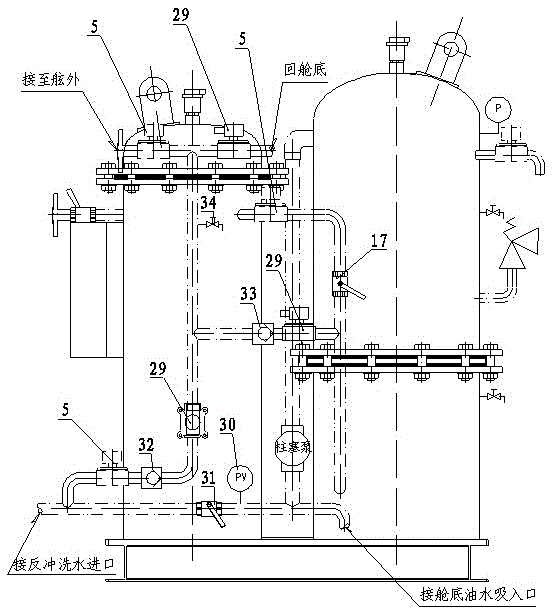

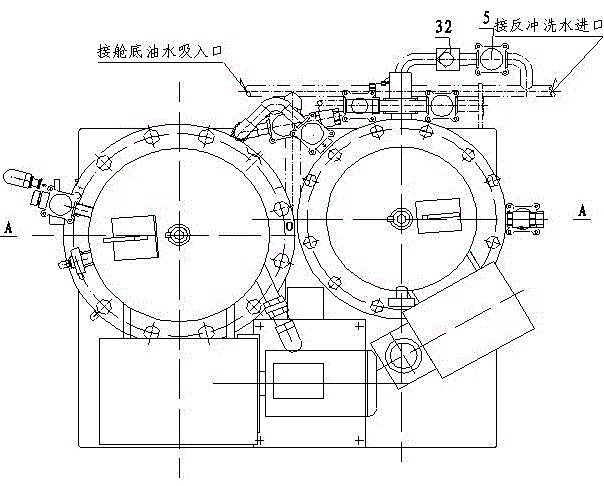

[0031] A cargo ship in Fangchenggang, Guangxi replaced the original separation device, and used the marine oil-water separator of the present invention to separate the bilge oil and water in the machinery space of the ship. When working, open the power switch of the electric plunger pump group 12 to start the plunger pump, the pump group promptly sucks the oily bilge water in the engine room, and the oily bilge water enters the primary filter. Due to the centrifugal effect of the flow, the oil particles continue to increase, and the enlarged oil particles float to the oil collection chamber above the first-stage filter cavity, and part of the dirty oil water containing smaller oil particles passes through the interception, adsorption, and absorption of the first-stage oil filter element 120. Aggregation, the formation of larger oil particles also float up to the oil collection chamber. A liquid level electrode is installed in the oil collection chamber. When the oil level reac...

Embodiment 2

[0033] A wharf in Fangchenggang, Guangxi, uses the marine oil-water separator of the present invention to separate the oily water from the oily sewage treatment site. When working, open the power switch of the electric plunger pump group 12 to start the plunger pump, the pump group promptly sucks the oily bilge water in the engine room, and the oily bilge water enters the primary filter. Due to the centrifugal effect of the flow, the oil particles continue to increase, and the enlarged oil particles float to the oil collection chamber above the first-stage filter cavity, and part of the dirty oil water containing smaller oil particles passes through the interception, adsorption, and absorption of the first-stage oil filter element 120. Aggregation, the formation of larger oil particles also float up to the oil collection chamber. A liquid level electrode is installed in the oil collection chamber. When the oil level reaches a high level, the normally closed solenoid valve 5 op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com