Work machine with electrical and hydraulic service centers

A maintenance center and work machine technology, applied in the field of maintenance systems, which can solve the problems of parts located at high temperature, inconvenient maintenance, and a lot of time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

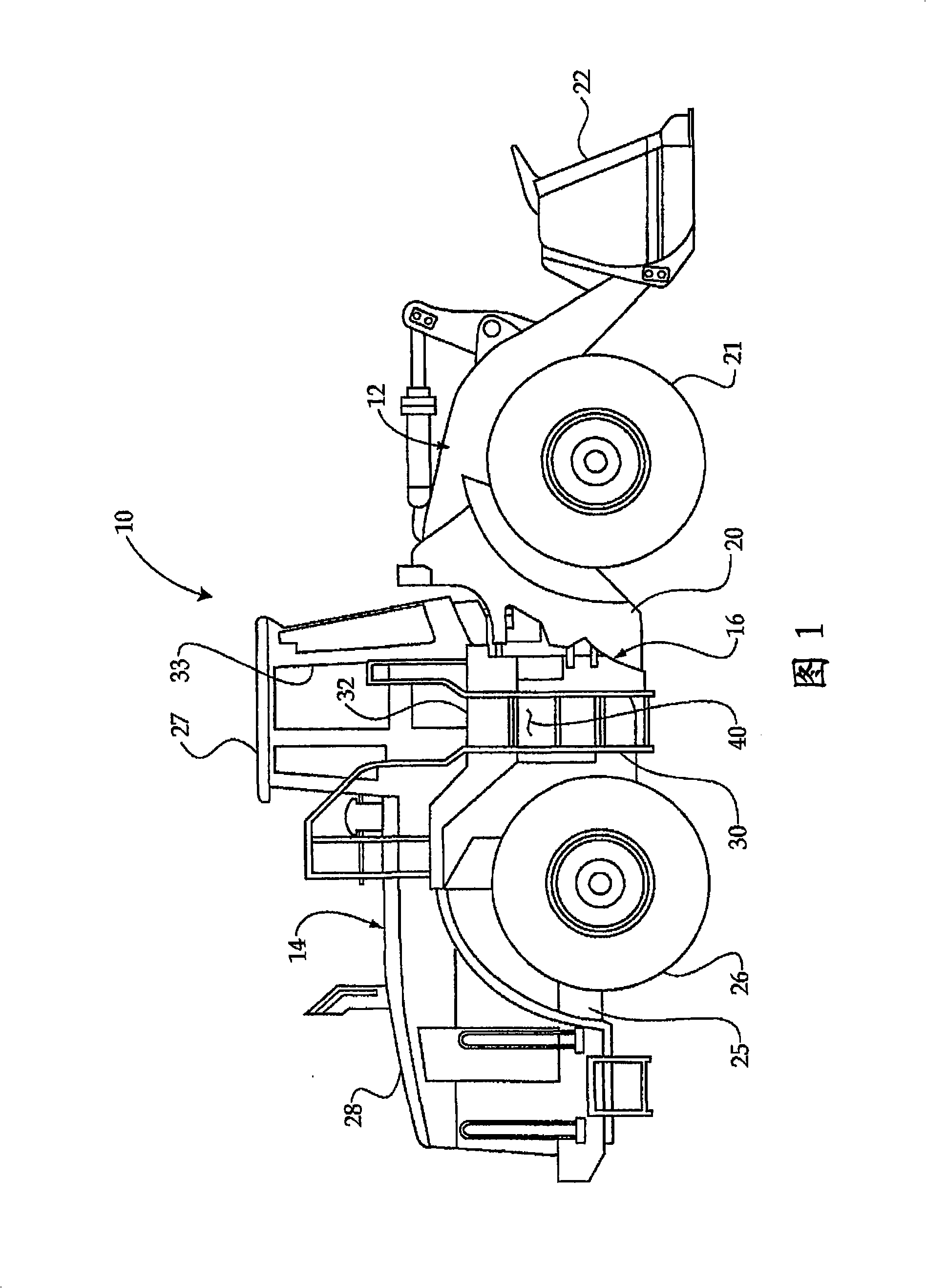

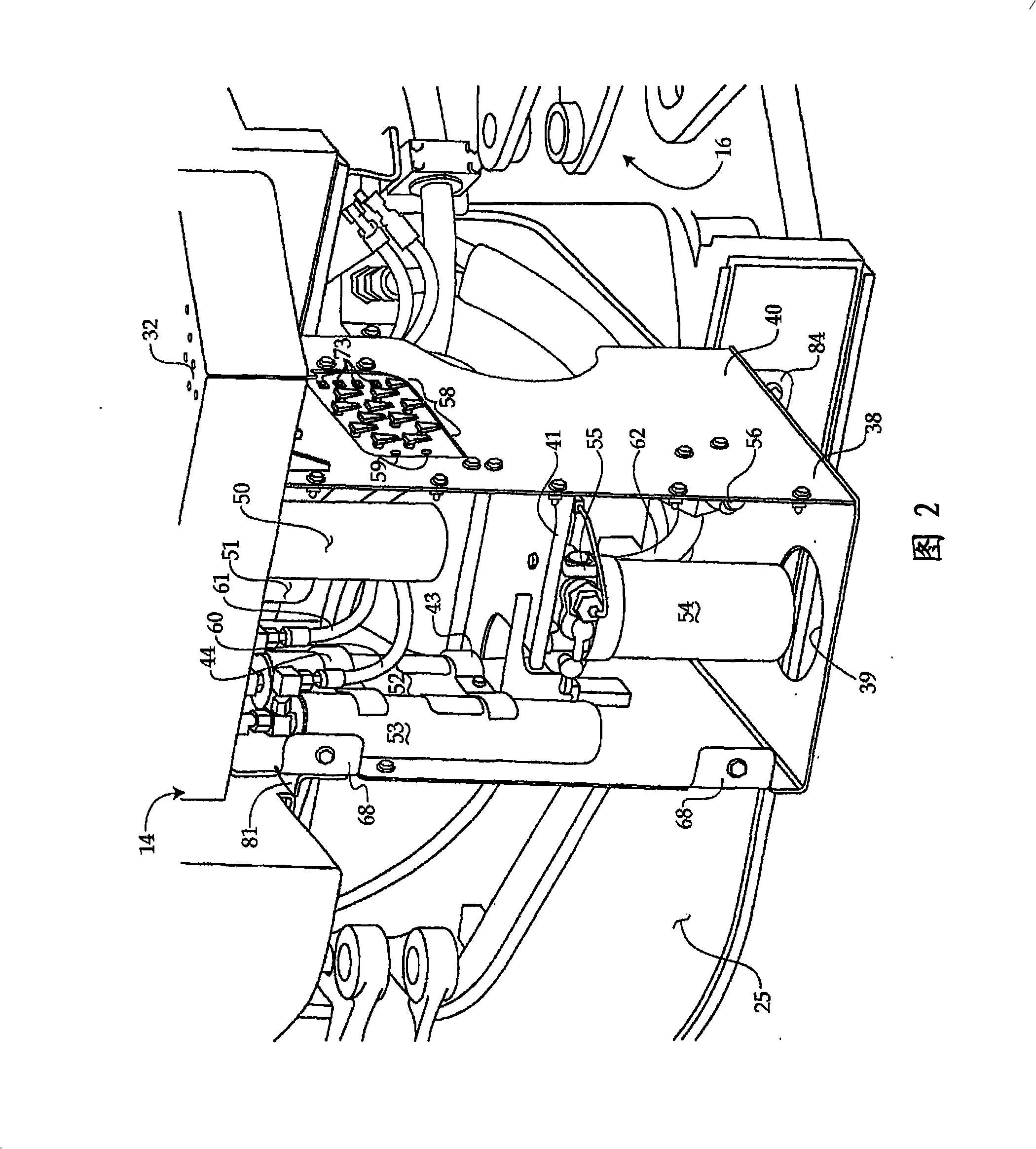

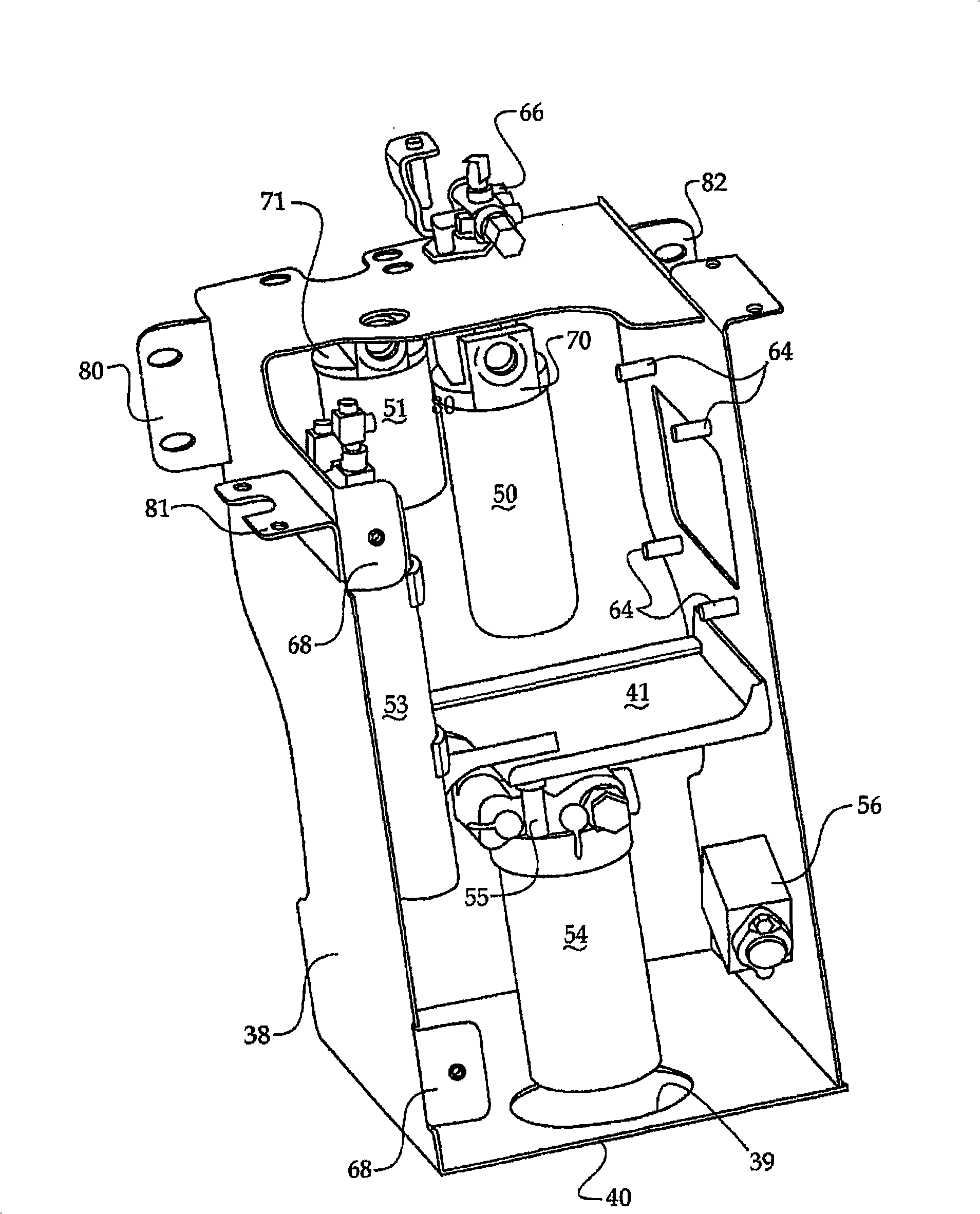

[0017] 1 to 5, the work machine 10 is shown as an articulated wheel loader with a chassis, which includes a front part 12 connected to a rear part 14 by a hinge 16. The hinge 16 allows the front frame 20 to pivot relative to the rear frame 25 about a vertical axis. The steering of the working machine 10 can be achieved in a conventional manner by a suitable actuator through a hinge 16. The front part 12 includes a front frame 20, a pair of front wheels 21 and a movable bucket 22. The rear part 14 includes a rear frame 25, a pair of rear wheels 26, a cab 27 and an engine 28. The operation room 27 can be reached from the right side through the step 30, the step 32 and the door 33 or the other step 130, 131, the step 132 and the left side door (not shown) on the left side (FIG. 5). The operator reaches the operating room or cab 27 upwards by climbing up the stairs 30 and standing on the stairs 32 on the right side. The door 33 can then be opened, and the operator enters the cab 27. Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com