Method for controlling a filter maintenance indicator

A technology of indicators and liquid filters, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of increasing the pressure damage of the main casing of the transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

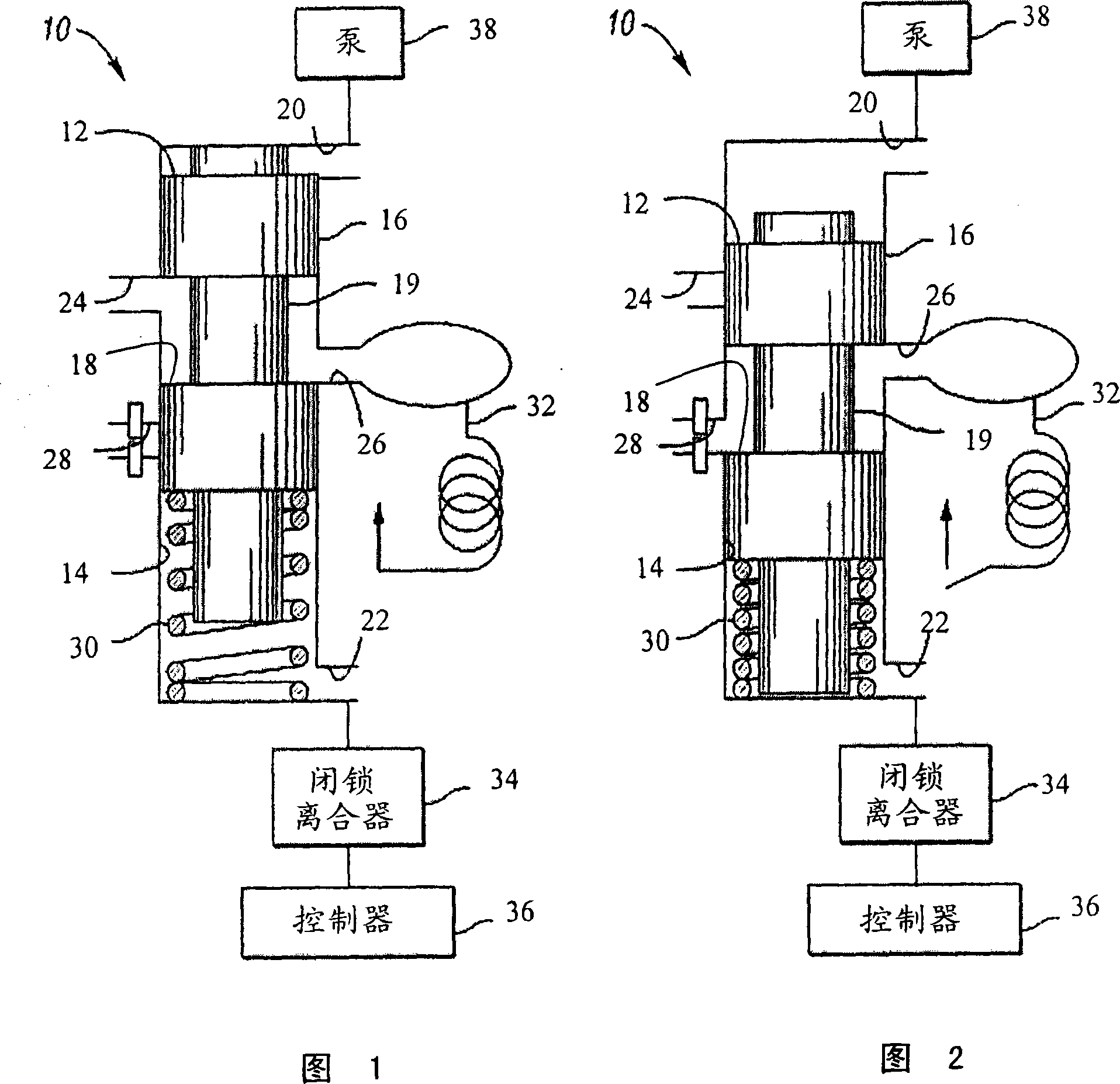

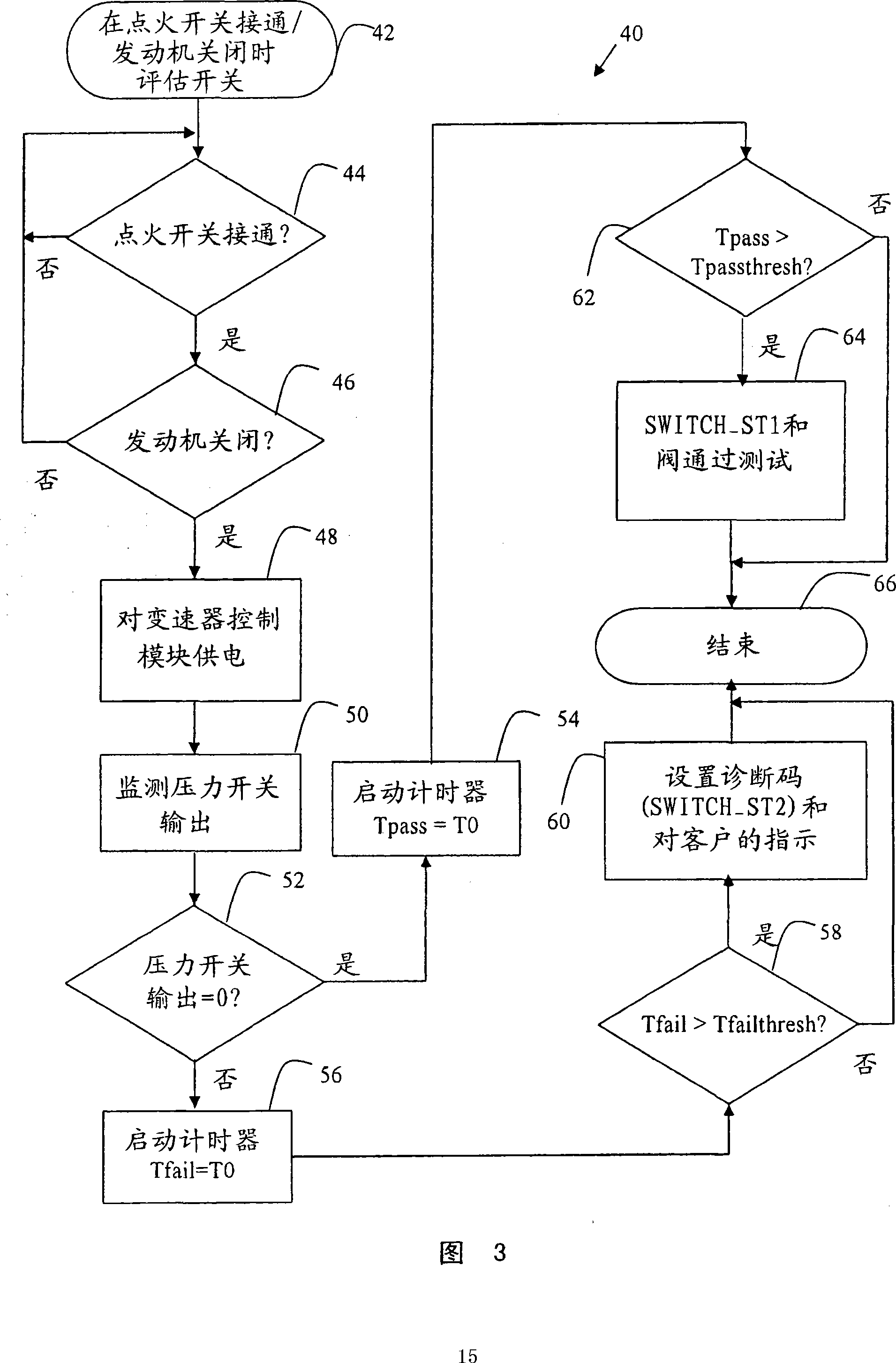

[0020] Referring to the drawings, in which like reference numerals designate like parts, a filter state detection device 10 is illustrated in FIG. 1 . The device 10 includes a valve 12 housed in a cavity 14 . Valve 12 is movable from a first position, shown in FIG. 1 , to a second position, shown in FIG. 2 . Valve 12 preferably includes a first land 16 and a second land 18 connected by an intermediate shaft portion 19 . The first and second lands 16 , 18 have the same diameter which is larger than the diameter of the intermediate shaft portion 19 . Cavity 14 has a first inlet 20 , a second inlet 22 , an outlet 24 , a switch port 26 , and an activation port 28 . Fluid enters cavity 14 through first inlet 20 at an inlet pressure equal to the inlet pressure of the fluid filter (ie, transmission fluid pressure) and through second inlet 22 into cavity 14 at an outlet pressure equal to the filter's discharge pressure. Liquid entering the first inlet 20 impacts the valve 12, tendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com