Method for uniform distribution of greasing substance on solid surface, apparatus and application thereof

A technology for lubricating substances and solid surfaces, which is applied in the field of uniform lubrication of solid surfaces, can solve the problems that powder solid lubrication cannot be used well, affects the performance and quality of powder metallurgy parts, and the distribution of powder lubricants is not uniform enough. Mass production, easy to promote and use, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

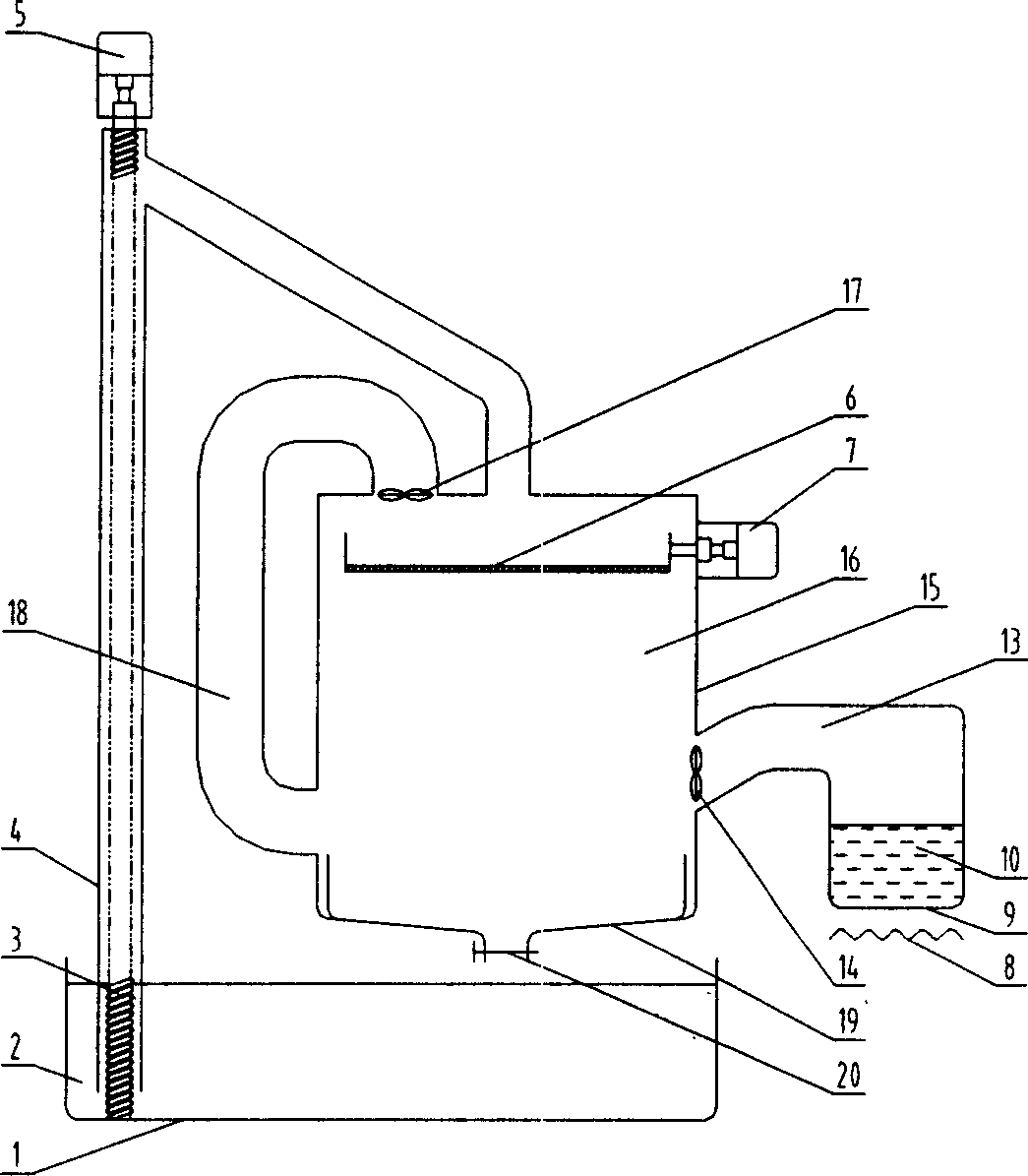

[0027] The specific structure of the present invention is as figure 1 shown by figure 1 It can be seen that the device of the present invention includes a powder lifting mechanism, a working chamber, and a lubricating substance vaporization assembly. The powder lifting mechanism is arranged outside the working chamber, and the lubricating substance vaporization assembly communicates with the lower part of the working chamber through a pipeline. The powder lifting mechanism is composed of a container 1, a central rod shaft 3 with helical blades, a powder conveying pipe 4, and a motor 5; 1. The container 19 for collecting powder is connected to form;

[0028]The method realized by the foregoing device is: the motor 5 drives the central rod shaft 3 with the helical blade to rotate, and the mixed and prepared powder raw material 2 (iron, copper, graphite mixed with iron, copper, and graphite) that is installed in the container 1 is prepared and processed through vacuum drying. P...

Embodiment 2

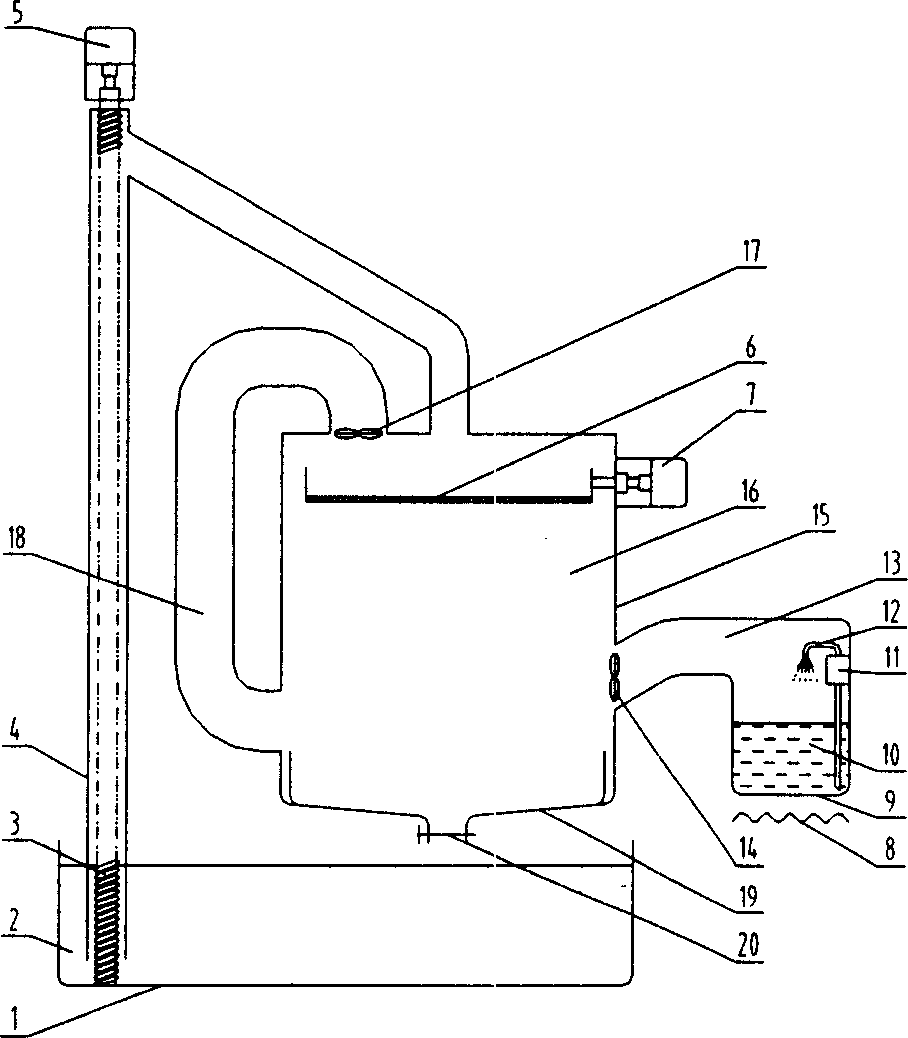

[0030] Another specific form of the device of the present invention is as figure 2 shown by figure 2 Visible, this device is basically the same as embodiment 1, and its difference is: lubricating substance vaporization device is made of container 9, heating element 8, oil pump 11, sprayer 12; The inlet of the pump is connected with a pipeline extending into the container 9 of lubricant, and the outlet of the oil pump 11 is connected with the sprayer 12 through the pipeline. Its action process is: the oil pump 11 pumps up the lubricating oil 10 and atomizes it into oil vapor through the nozzle of the atomizer 12 .

Embodiment 3

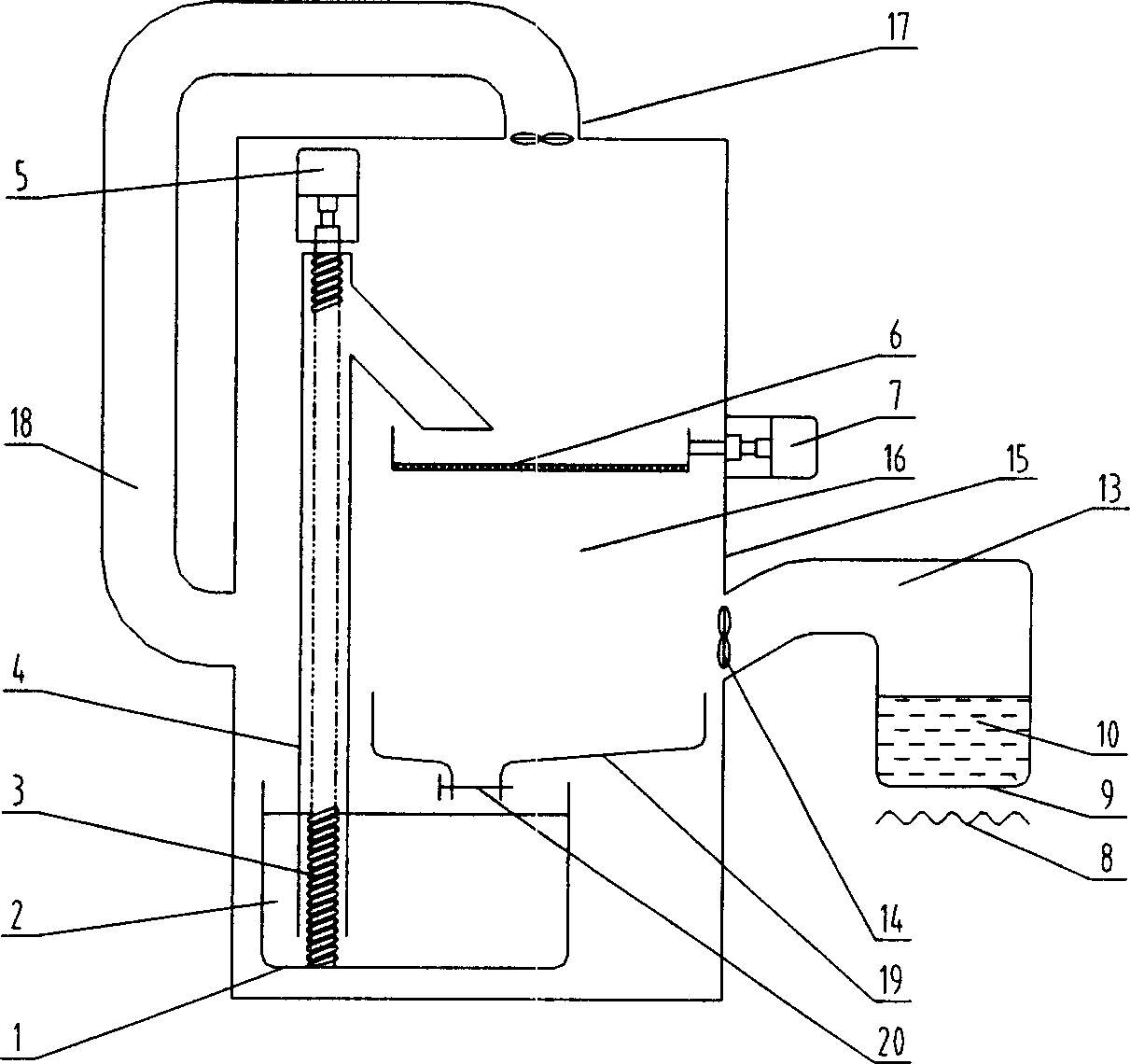

[0032] Another specific form of the device of the present invention is as image 3 shown by image 3 It can be seen that this device is basically the same as Embodiment 1, the difference is that: the powder lifting mechanism is inside the working chamber; the motor 5 drives the central rod shaft 3 with the helical blade to rotate, and the powder raw material 2 contained in the container 1 is passed through The powder conveying pipe 4 is lifted and transported to the powder vibrating sieve 6 at a high position, the vibration mechanism 7 drives the vibrating sieve 6 to vibrate, so that the powder falls from a high place in a dispersed manner, and the heating element 8 is energized to heat the container 9 containing the lubricating oil 10, so that The temperature of the lubricating oil 10 rises and vaporizes into oil vapor. The oil vapor enters the working chamber of the container 15 through the channel 13 under the action of the exhaust fan 14. The oil vapor flows from bottom to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com