Ternary boride Mo2NiB2 alloy powder for 3D printing and production process of ternary boride Mo2NiB2 alloy powder for 3D printing

A ternary boride, 3D printing technology, applied in the field of 3D printing materials, can solve the problems of clogging, powder particle size distribution, powder shape that cannot reach 3D printing powder, and low powder yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

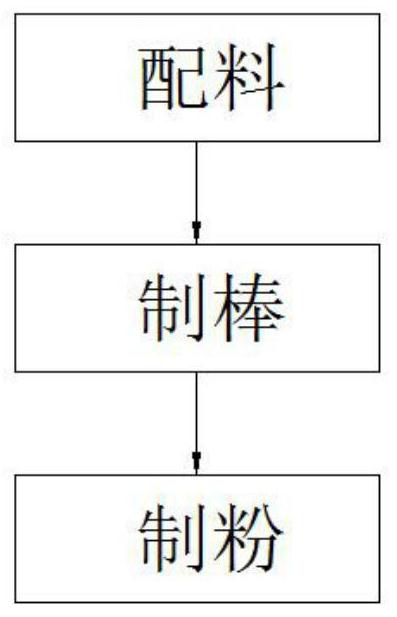

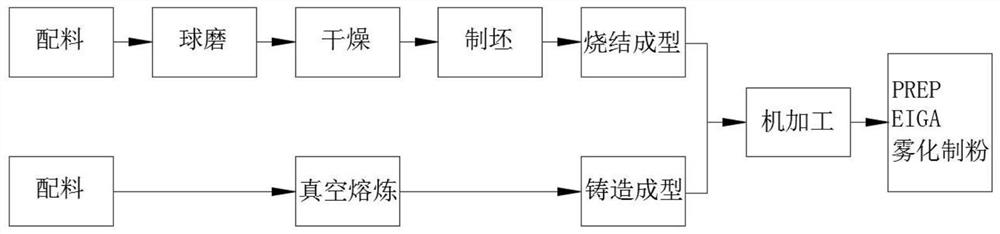

[0032] Example 1: A 3D printing ternary boride Mo provided in this example 2 NiB 2 Alloy powder and its production process, see figure 1 , the process steps are as follows:

[0033] (1) Ingredients: wet ball milling has more obvious advantages in terms of particle size distribution, anti-oxidation of powder, segregation and agglomeration of powder for preparing powder, so wet ball milling process is preferably used in this embodiment. Prepare the materials and their mass percentages as follows: B 3.3%, Mo 50%, Cr 10%, C 2%, V 0.5%, Nb 2%, W 0.5%, Ce 2%, Mn 4%, Ta0.3%, Ti 0.6%, binder 3%, Ni23%;

[0034] (2) Rod making: mix raw materials B, Mo, Cr, C, V, Nb, W, Ce, Mn, Ta, Ti, Ni and binder according to the formula. The binder is preferably paraffin. In other embodiments, the binder can be selected from PEG, rubber or resin, etc.; mixed with any one or more solvents such as absolute ethanol or methanol, acetone, n-heptane, n-hexane, etc. The azeotropic solvent is used as t...

Embodiment 2

[0041] Embodiment 2: A kind of 3D printing ternary boride Mo provided by this embodiment 2 NiB 2 Alloy powder and its production process are basically the same as in Example 1, except that the elements and their mass percentages are as follows: B 7%, Mo 25%, Cr 15%, C 1%, V 5%, Nb 3%, W 4%, Ce 0.5%, Mn 1%, Ta 1%, Ti 2%, binder 6%, Ni 29.5%.

Embodiment 3

[0042] Embodiment 3: A kind of 3D printing ternary boride Mo provided by this embodiment 2 NiB 2 Alloy powder and its production process are basically the same as in Example 1, except that the elements and their mass percentages are as follows: B 5%, Mo 30%, Cr 4%, C 0.5%, V 3%, Nb 1.5% , W 6%, Ce 0.6%, Mn 3%, Ta 0.7%, Ti 0.7%, binder 4%, Ni41%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com