Suspension apparatus of screw conveyer

A screw conveyor and suspension device technology, applied in packaging and other directions, can solve problems such as poor lubrication, shutdown for maintenance and replacement, short service life, etc., and achieve the effects of increasing production efficiency, avoiding bearing wear and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

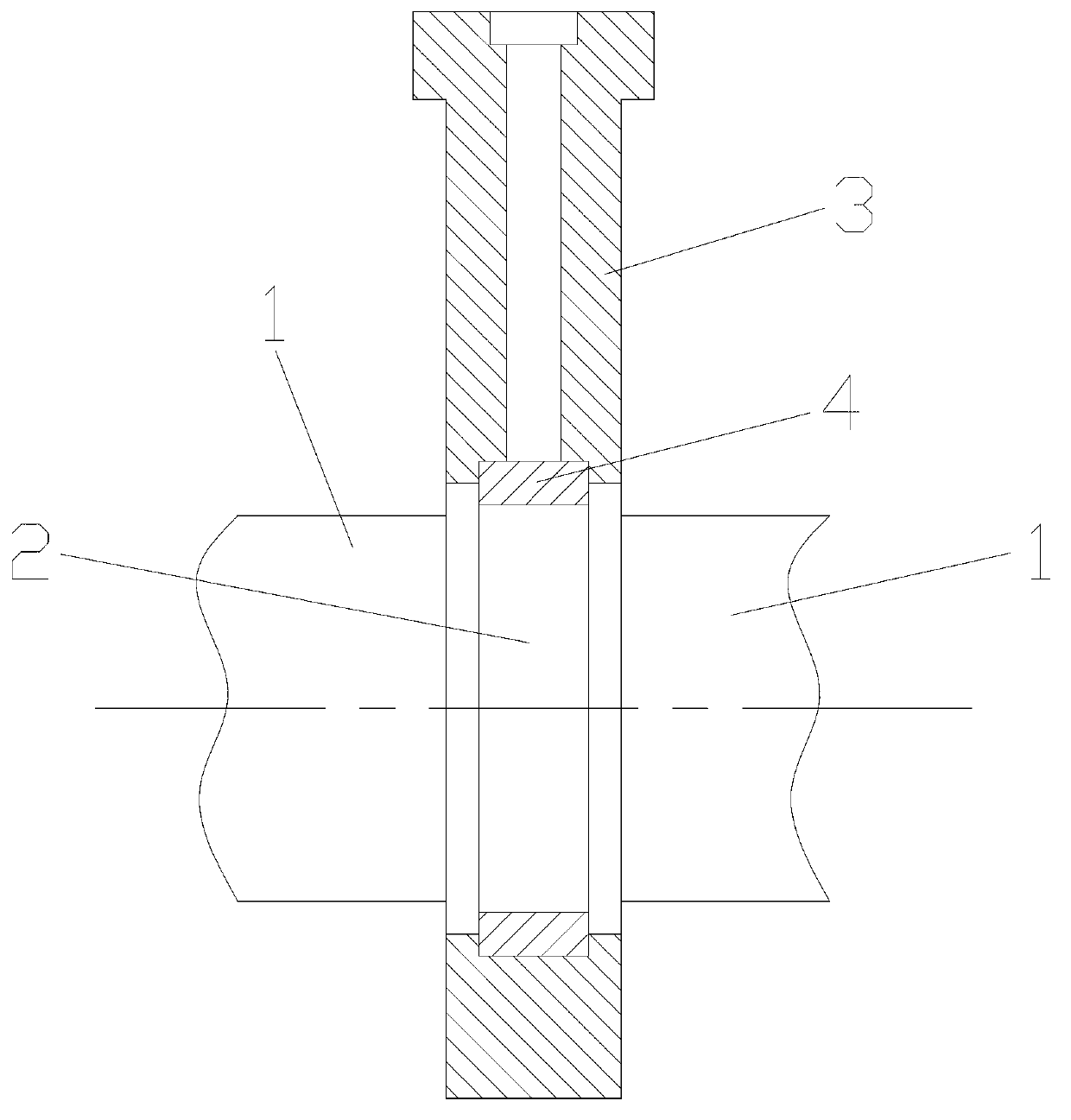

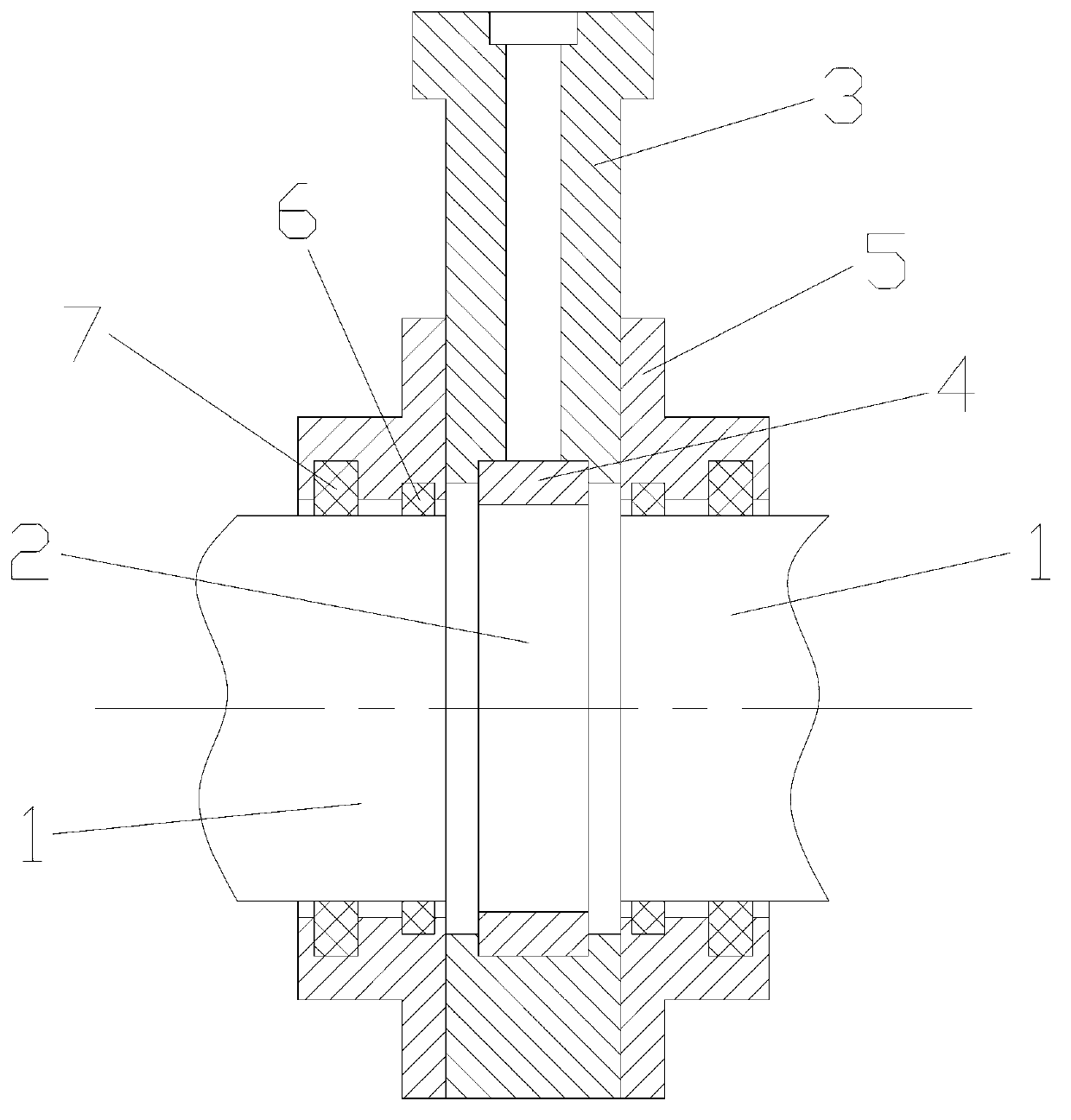

[0013] The present invention is described below in conjunction with accompanying drawing.

[0014] as attached figure 2 The shown suspension device of a screw conveyor according to the present invention includes a connecting flange shaft 2 connecting two rotating shafts 1 and a bearing seat 3 installed on the connecting flange shaft 2, and the connecting flange shaft 2 and Bearings 4 are provided between the bearing seats 3, and two glands 5 are set on the rotating shaft 1; the two glands 5 are respectively located on both sides of the bearing seat 3; each gland 5 is connected to the rotating shaft There is a sealing assembly in the first room; the sealing assembly includes a felt ring 6 and an oil seal 7; the felt ring 6 and the oil seal 7 are arranged sequentially from the inside to the outside.

[0015] When the screw conveyor suspension device of the present invention is in use, the combined seal of the felt ring and the oil seal can prevent dust from easily entering the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com