Wear-resistant material with thermal response and self-lubricating properties and preparation method thereof

A wear-resistant material and self-lubricating technology, applied in the field of wear-resistant materials, can solve problems such as consumption, low work efficiency, and increased production costs, and achieve good application prospects, good wear resistance, and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principles and features of the present invention are described below, and the examples are only used to explain the present invention, but not to limit the scope of the present invention.

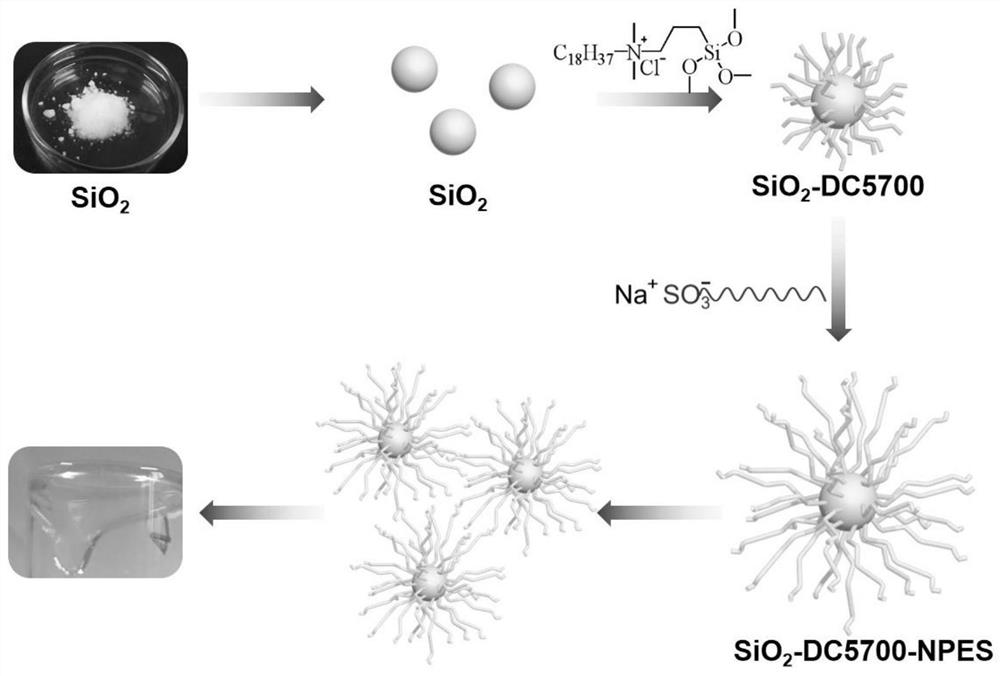

[0018] A preparation method of a wear-resistant material with thermal response and self-lubricating properties, comprising the following steps:

[0019] Step 1. Dissolve both the high polymer and the nano fluid prepared by the ion exchange method in an organic solvent, and stir to obtain a mixed solution. The mass concentration of the nano fluid in the mixed solution is 10%-30%. The mass concentration of the substance is 10%-30%;

[0020] Step 2. The mixed solution is injected into the mold, and air-dried at room temperature to obtain a wear-resistant material with thermal response and self-lubricating properties.

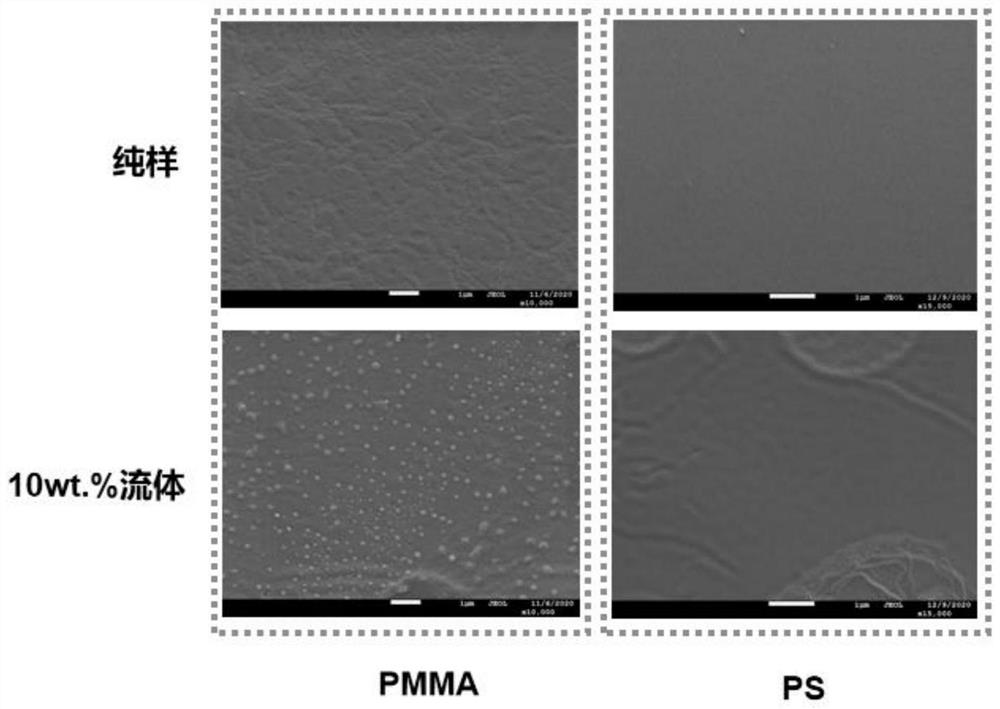

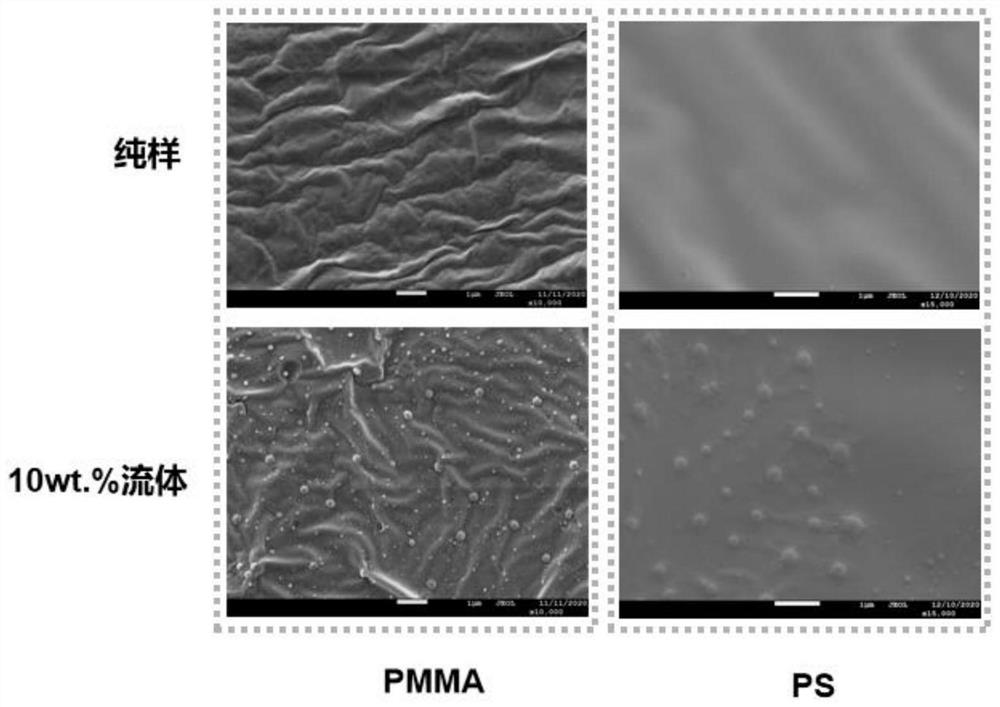

[0021] As an embodiment, the high polymer in the step 1 is any one of polystyrene, polymethyl methacrylate and polyvinylidene fluoride.

[0022] As an embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com