Manufacturing of low-friction elements

A low-friction, mechanical component technology, applied in the direction of engine components, pressure inorganic powder coating, coating, etc., can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In this description, identical or directly related features in different figures and embodiments are denoted by the same reference numerals.

[0027] In this specification, the term "transverse" is used. In this specification, the intended meaning of motion in two intersecting directions on or along a surface is defined by two non-parallel motions intersecting a point on the surface. Figure 10A Two examples of motion considered non-intersecting are shown. Figure 10B Three non-exclusive examples of cross motion are shown. In these examples, there is at least one point on the aforementioned surface passing through two non-parallel directions.

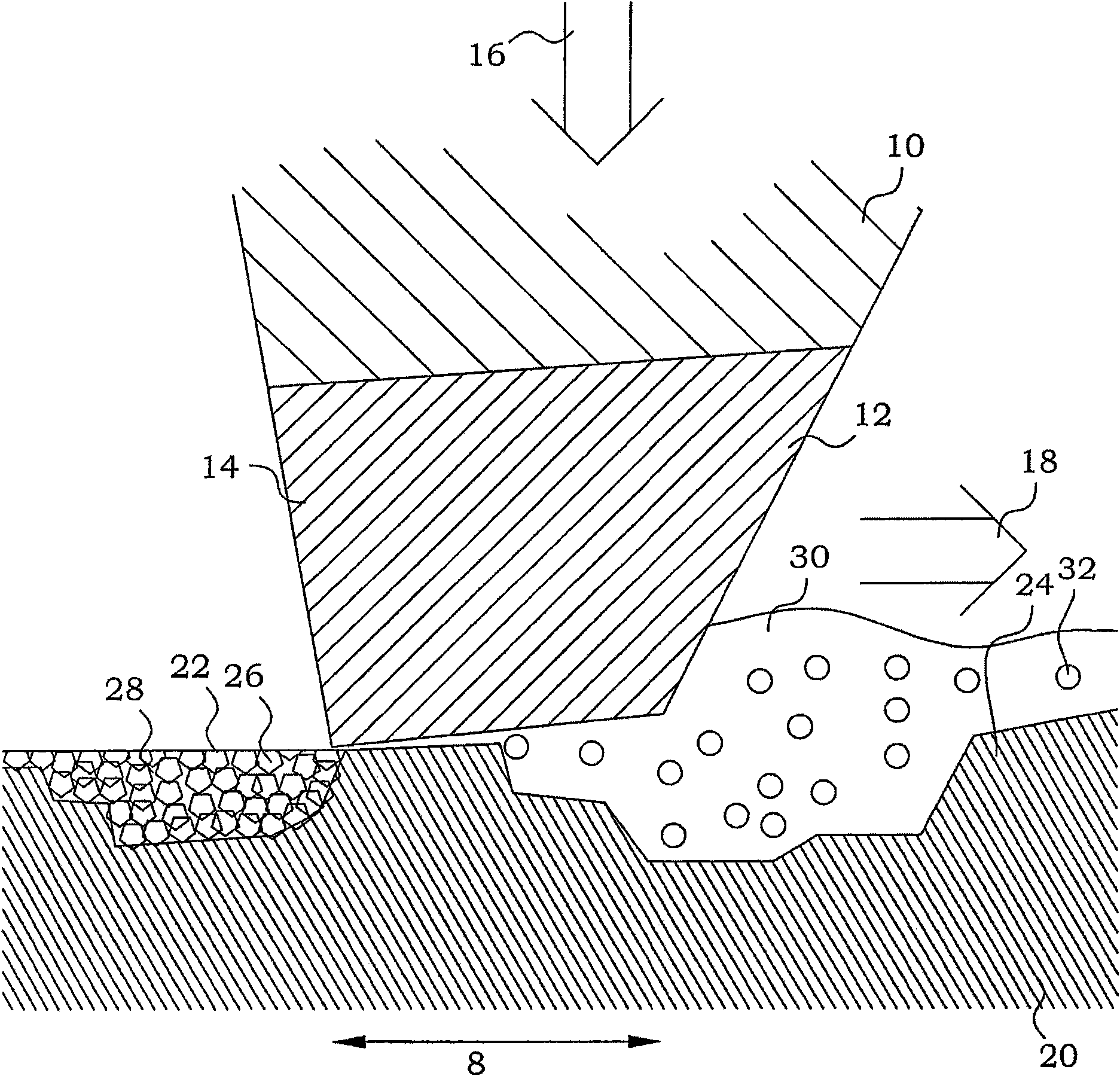

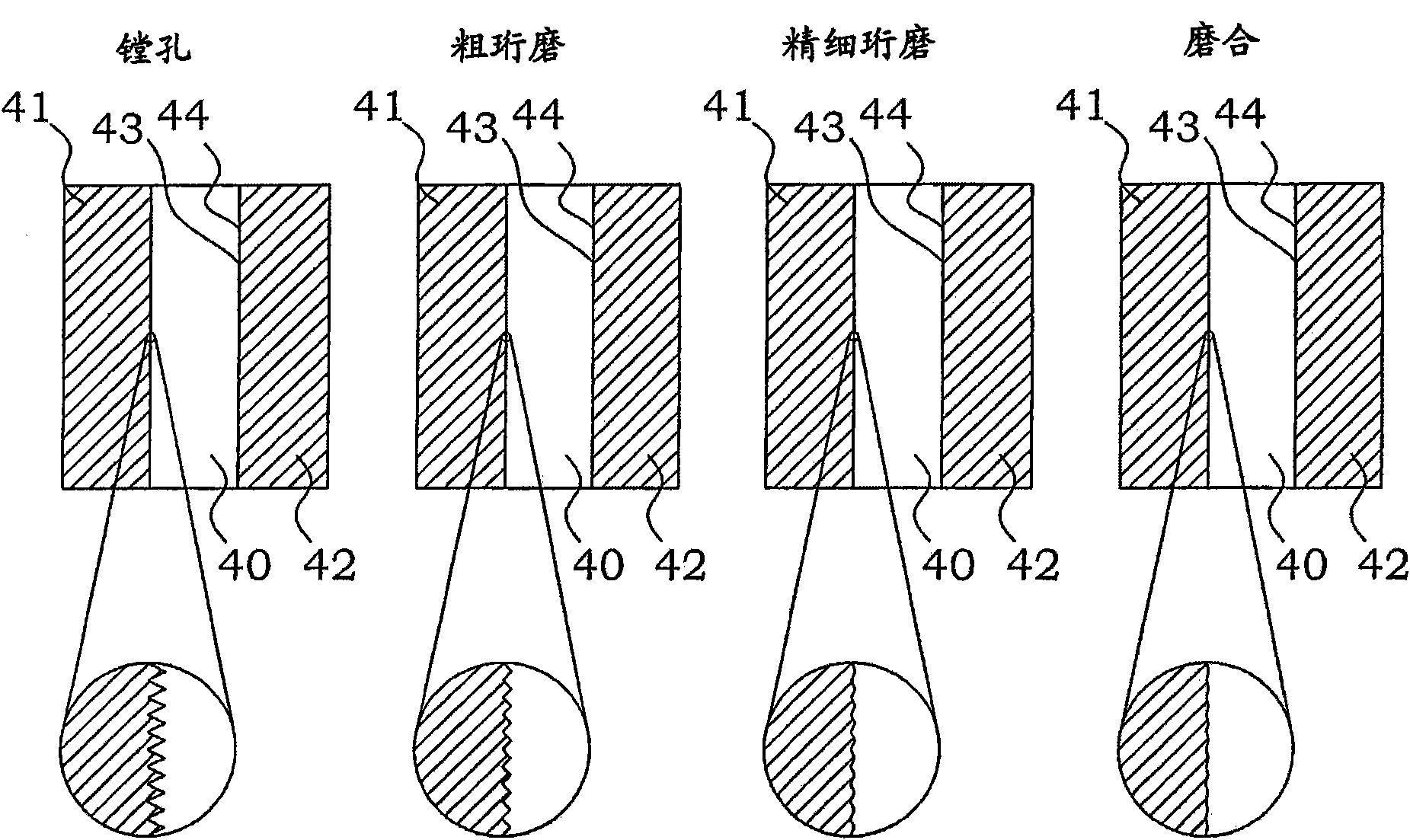

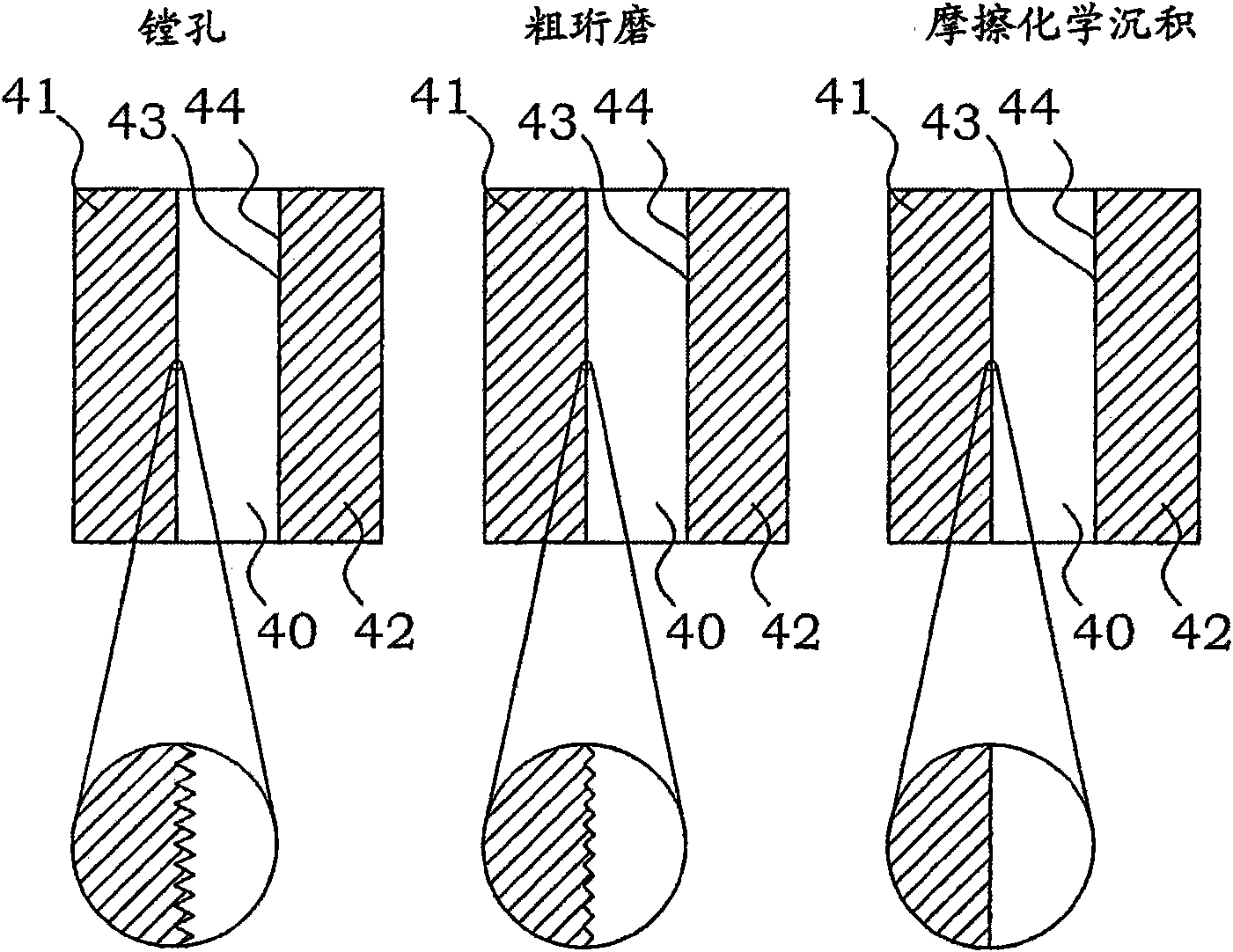

[0028] According to the invention, a surface with a solid lubricant is provided by direct tribochemical deposition onto the surface to be covered, preferably a relatively rough surface. Tribochemical deposition is well known in the field of friction and wear. For example, in a 2006 review of the doctoral dissertation "On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com