Micromechanical component for containing a lubricant substance

A technology for micromechanical components and components, which is applied in mechanically driven clocks, gear mechanisms, escapement mechanisms, etc., and can solve problems such as difficulty in forming a lubricating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

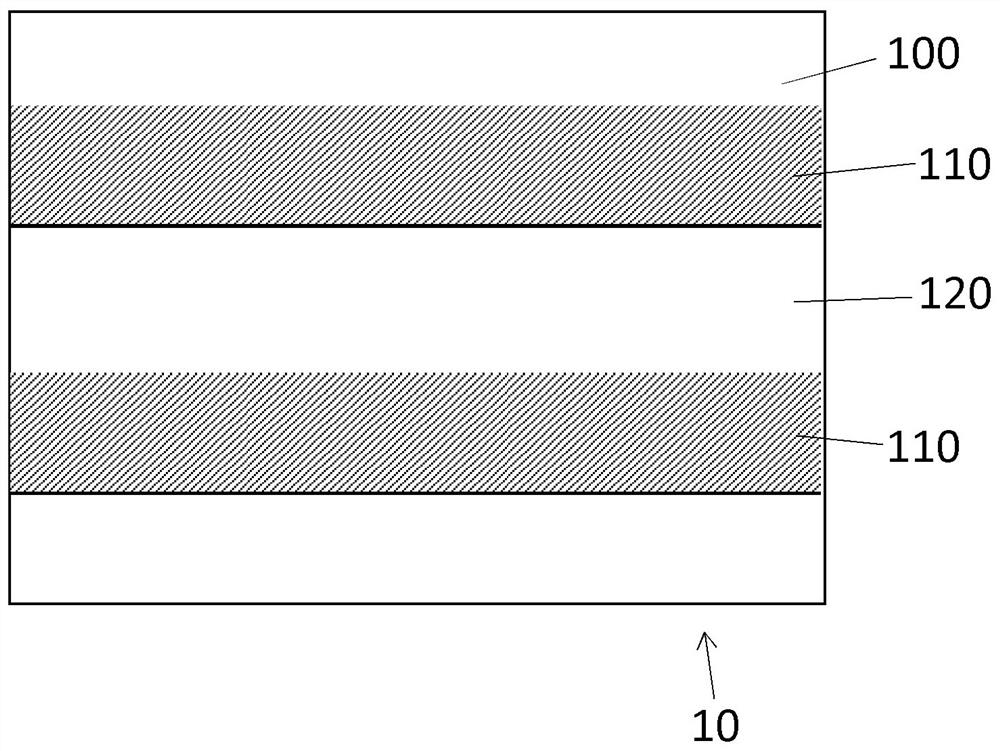

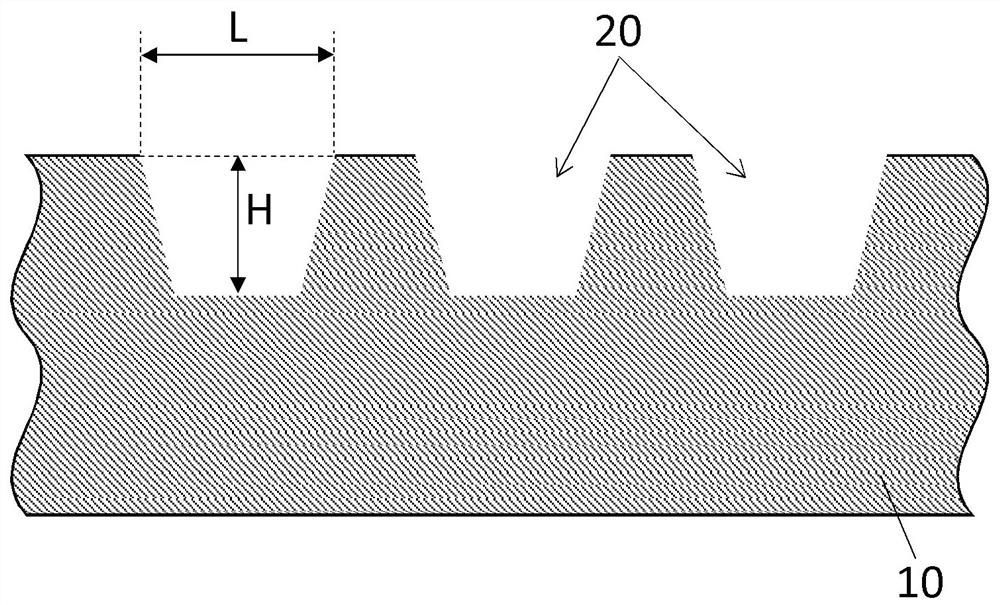

[0021] figure 1 A micromechanical component 10 for a timepiece mechanism according to one embodiment is schematically shown. Part 10 comprises at least one contact surface 100, at least a part of which is intended to make a sliding and / or pivoting contact, for example with another part of a timepiece mechanism.

[0022] Part 10 is made wholly or partly from carbon or aluminum oxide (Al 2 o 3 ) composed of crystalline mineral materials. Preferably, the crystalline mineral material is natural or synthetic diamond, ruby, or sapphire. Other materials are also possible, such as polymers, metals or metal alloys, ceramics, silica, glass, silicon, and the like.

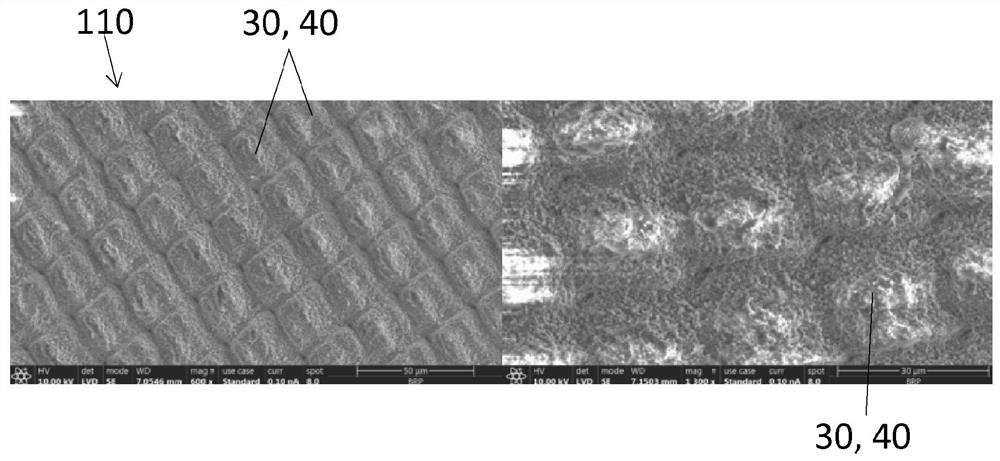

[0023] The component 10 consisting entirely or partially of crystalline mineral material comprises a contact surface 100 which partially comprises at least one microstructured region 110 . The microstructured region 110 may be more oleophobic than the non-microstructured contact surface 100 . Alternatively, the microstr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com