Method and apparatus for cylinder lubrication

A cylinder and equipment technology, applied in mechanical equipment, lubricating parts, pressure lubricants, etc., can solve the problems of high downtime, excess lubricating oil, lack of lubricating oil, etc., and achieve the effect of short downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

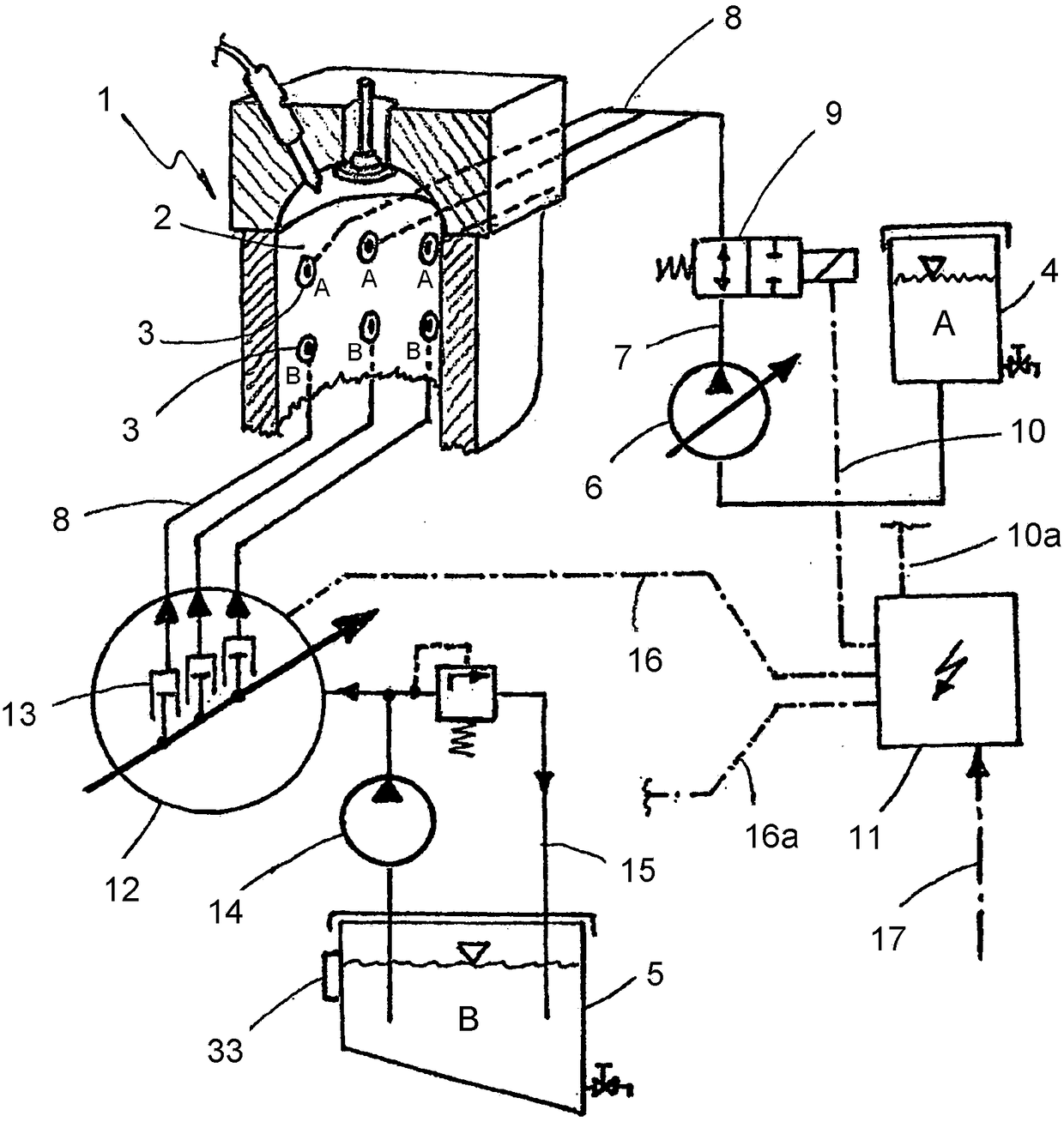

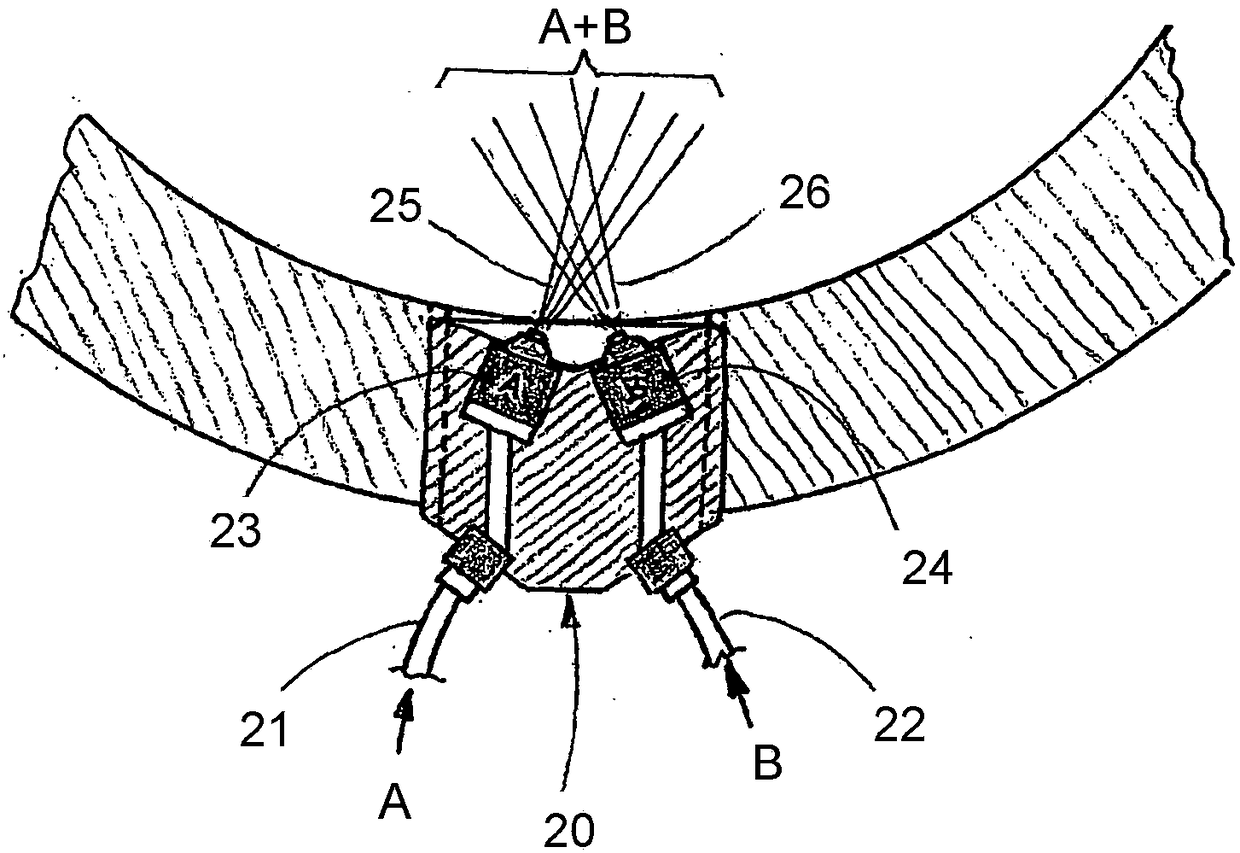

[0026] The main field of application of the invention is large internal combustion engines with crossheads, especially large two-stroke diesel engines with direct-flow scavenging, which are usually driven with heavy fuel oil. Heavy fuel oils can contain relatively high amounts of sulfur, which when combusted can lead to the formation of sulfuric acid and the like. Acids can attack the sliding surfaces of the piston and / or the cylinder liner and must therefore be neutralized to prevent this attack.

[0027] The construction and mode of operation of large engine types with direct-flow scavenging, such as two-stroke large diesel engines, are known per se and therefore only what is necessary for understanding the invention will be explained below.

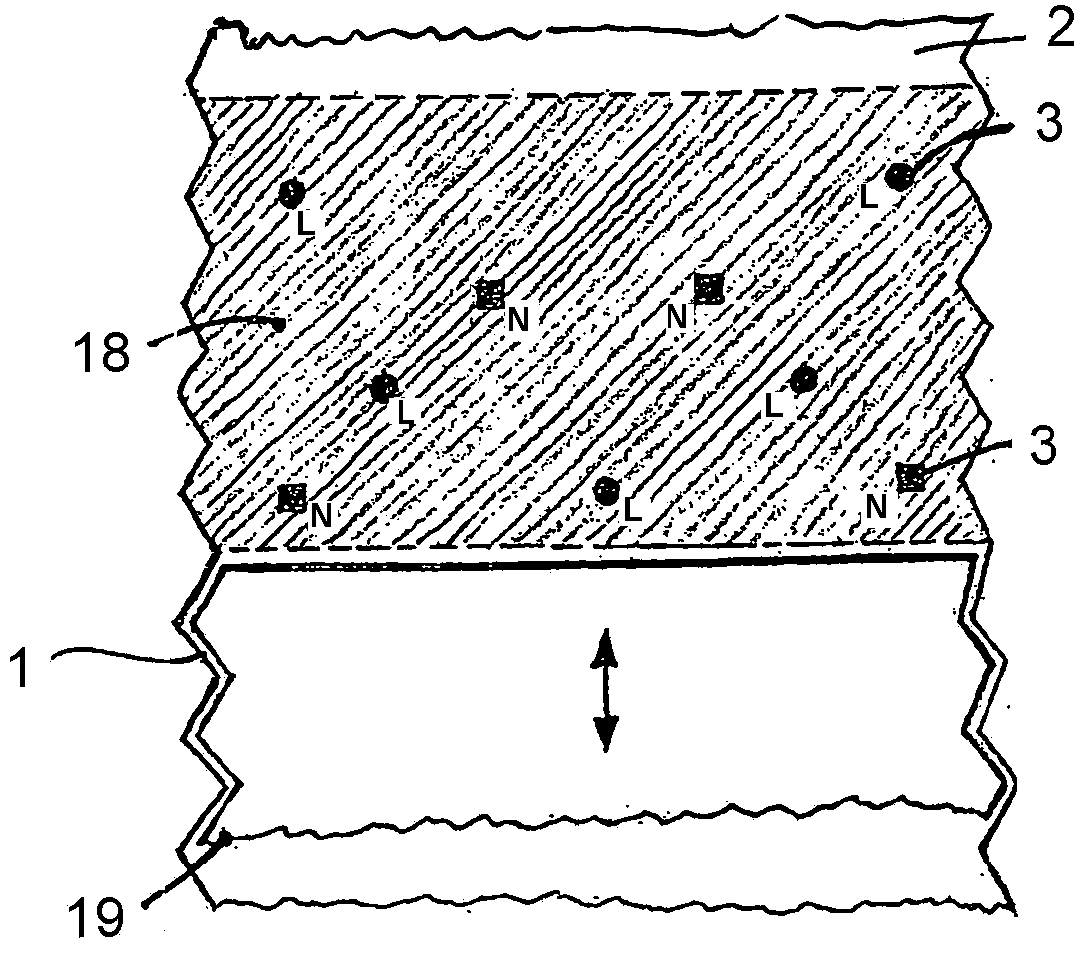

[0028] figure 1Cylinder 1 of such an engine is shown. Usually a plurality of such cylinders 1 are provided, preferably arranged in a row. An associated piston, not shown in detail here, which forms a movable delimitation of the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com