An automatic oil supply rocker arm fixing seat group and its implementation method

A technology of fixing seat and rocker arm assembly, which is applied in the directions of transmission parts, gear lubrication/cooling, belt/chain/gear, etc. It can solve problems such as excessive oil, inability to continuously supply oil, and complex oil supply structure, etc., to achieve The effect of simplifying the oil supply structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

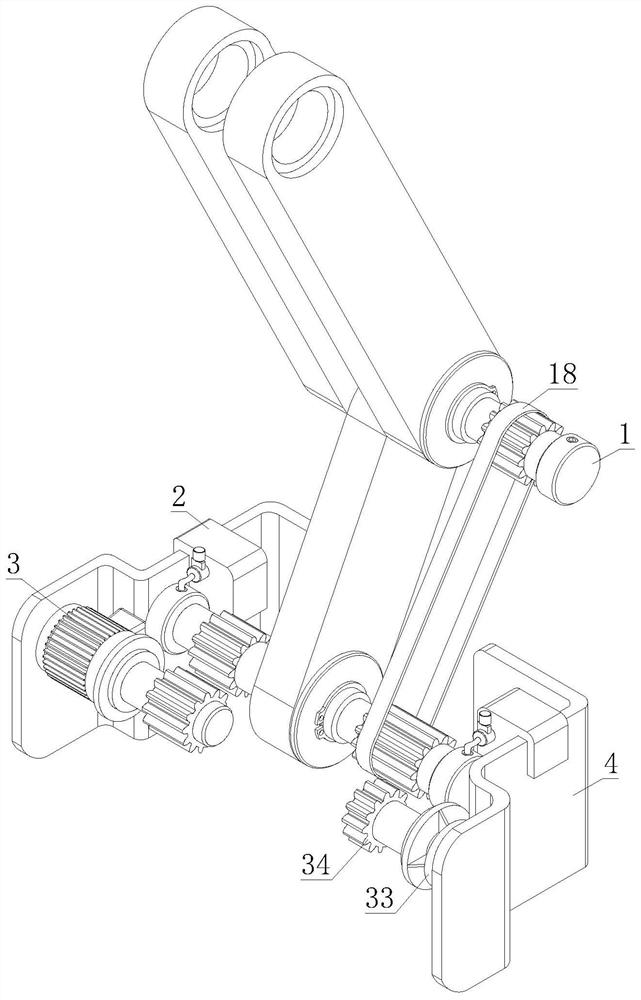

[0031] refer to Figure 8 , in order to better demonstrate the implementation process of the rocker arm holder group for automatic oil supply, this embodiment now proposes an implementation method for the rocker arm holder group for automatic oil supply, including the following steps:

[0032] S101: Preliminary oil supply, the oil pump 22 drives the oil in the oil tank 21 to enter the flow channel 19;

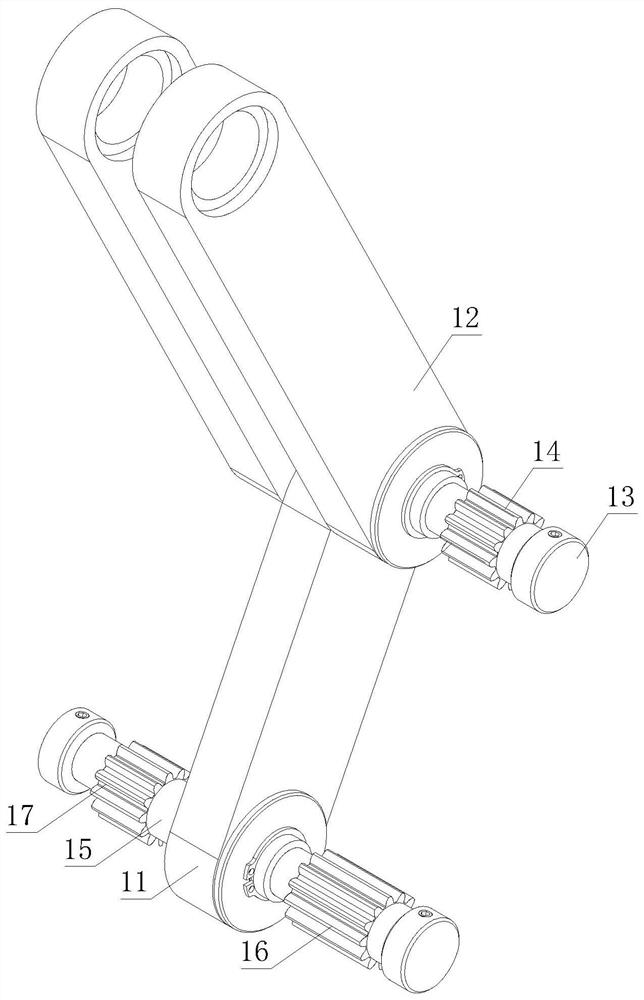

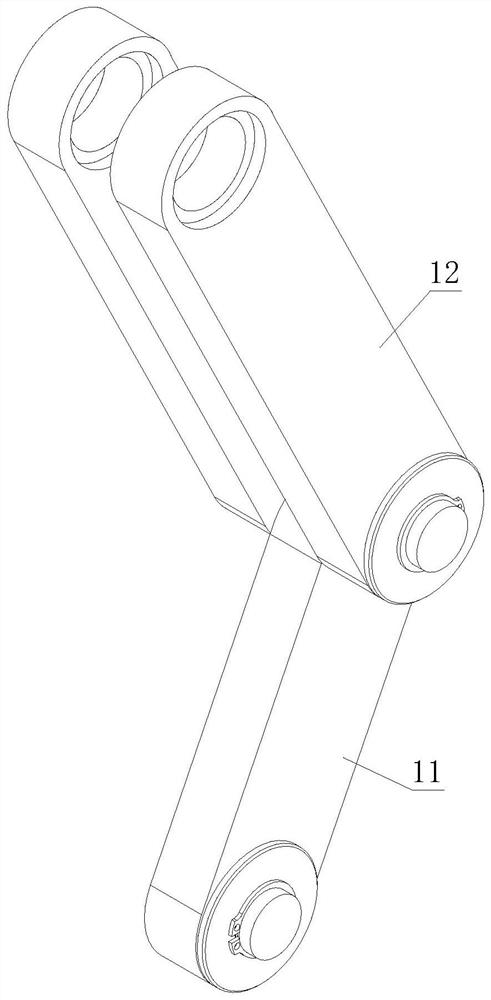

[0033] S102: Drive the rocker arm, the main motor 31 drives the main shaft 15 and the main rocker 11 to rotate, the auxiliary motor 33 drives the auxiliary shaft 13 and the auxiliary rocker 12 to rotate; the main motor 31 drives the main motor gear 32 to rotate, thereby driving the left main gear 17 , the main shaft 15 and the main rocker 11 rotate, the auxiliary motor 33 drives the auxiliary motor gear 34 to rotate, thereby driving the right main gear 16 to rotate, and the right main gear 16 drives the auxiliary gear 14, the auxiliary shaft 13 and the auxiliary rocker 12 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com