Coated split handrail

A wrapping, handrail technology, applied in the directions of handrails, transportation and packaging, superstructure sub-assembly, etc., can solve problems such as skin slack, accumulation of wrinkles at the corners of the skin, and the handrail cover not completely covering the wrinkles, etc. Achieve the effect of improving the appearance, delaying the time of wrinkles and sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

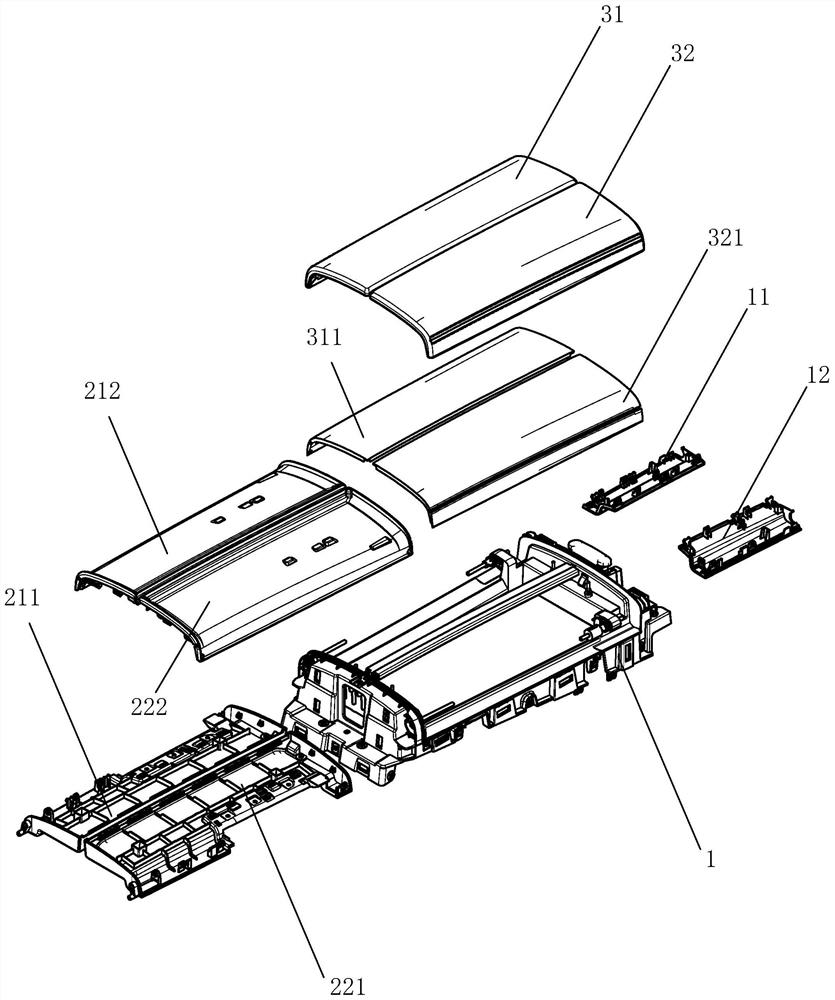

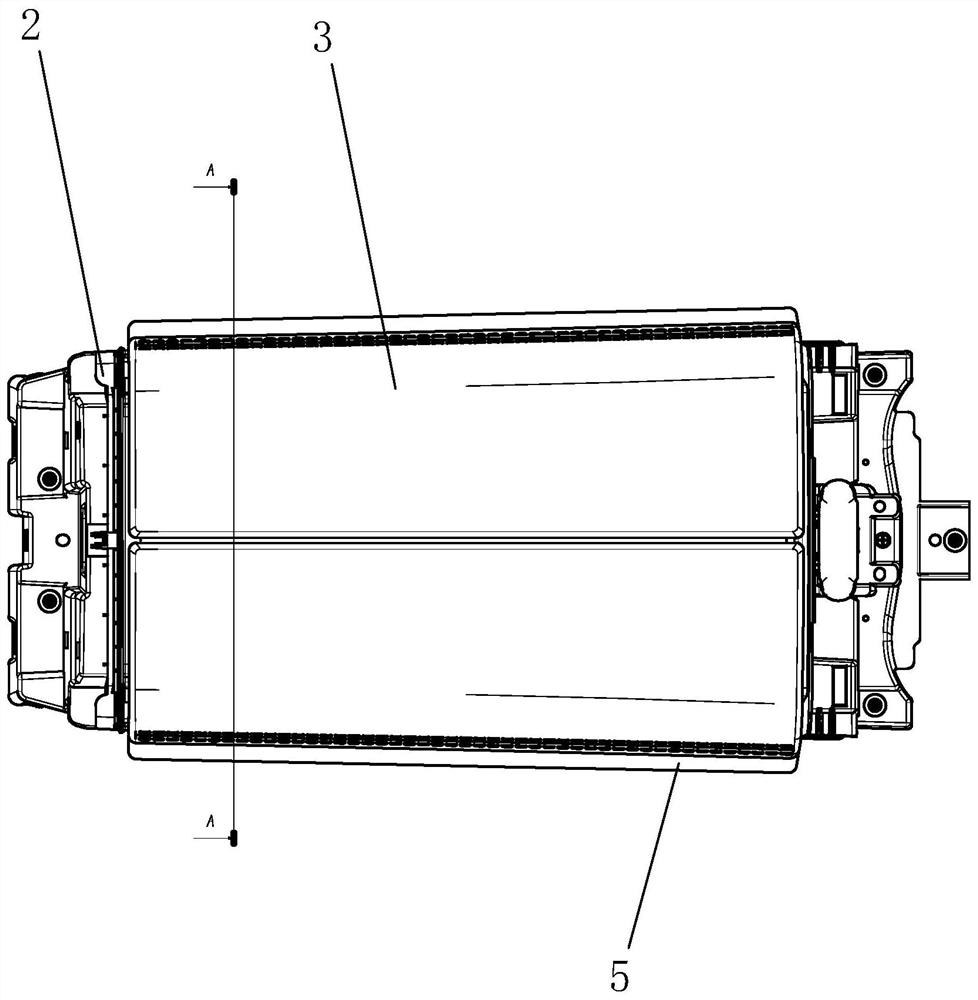

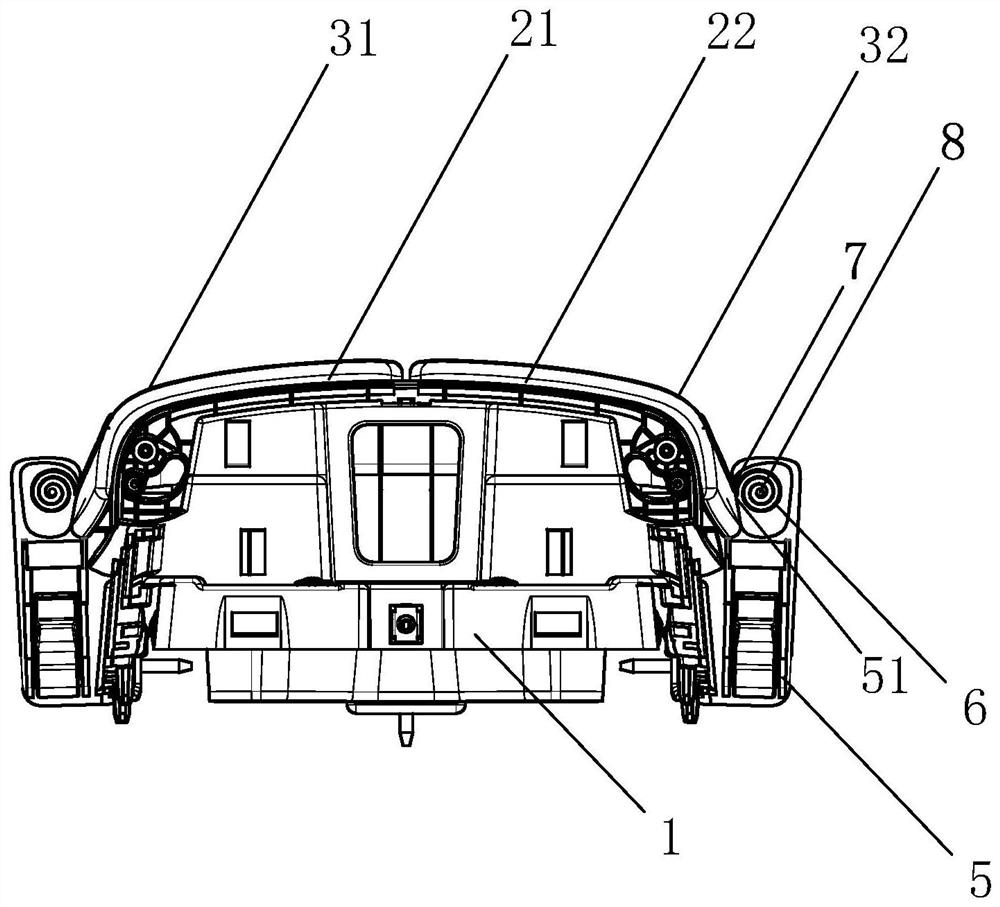

[0023] Such as figure 1 , 4 As shown, a covered split armrest includes an armrest frame 1, a split cover plate assembly 2 is arranged on the armrest frame 1, a skin layer 3 is covered on the cover plate assembly, and the cover An accommodating groove 4 is provided at the corner of the bottom surface of the panel assembly, and the corners of the skin layer 3 are snapped into the accommodating groove 4 . The receiving groove 4 is arranged along the diagonal of the cover plate assembly. The accommodating groove 4 is used to accommodate the folds formed by sewing at the corners of the skin layer 3, so as to avoid the reduction of the overall appearance of the handrail caused by the exposure of the folds; Size margin, the accommodating groove 4 can accommodate excess scraps of the skin layer 3, avoiding the cumbersome steps of re-calibrating the skin layer 3 in the hemming process, and effectively improving the processing efficiency of the hemming process. The accommodating groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com