A sealing system, an industrial robot with a sealing system, and a method for providing a sealing surface

A sealing system and sealing surface technology, applied in the petroleum industry, engine sealing, manipulators, etc., to achieve the effect of low price, high durability and good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

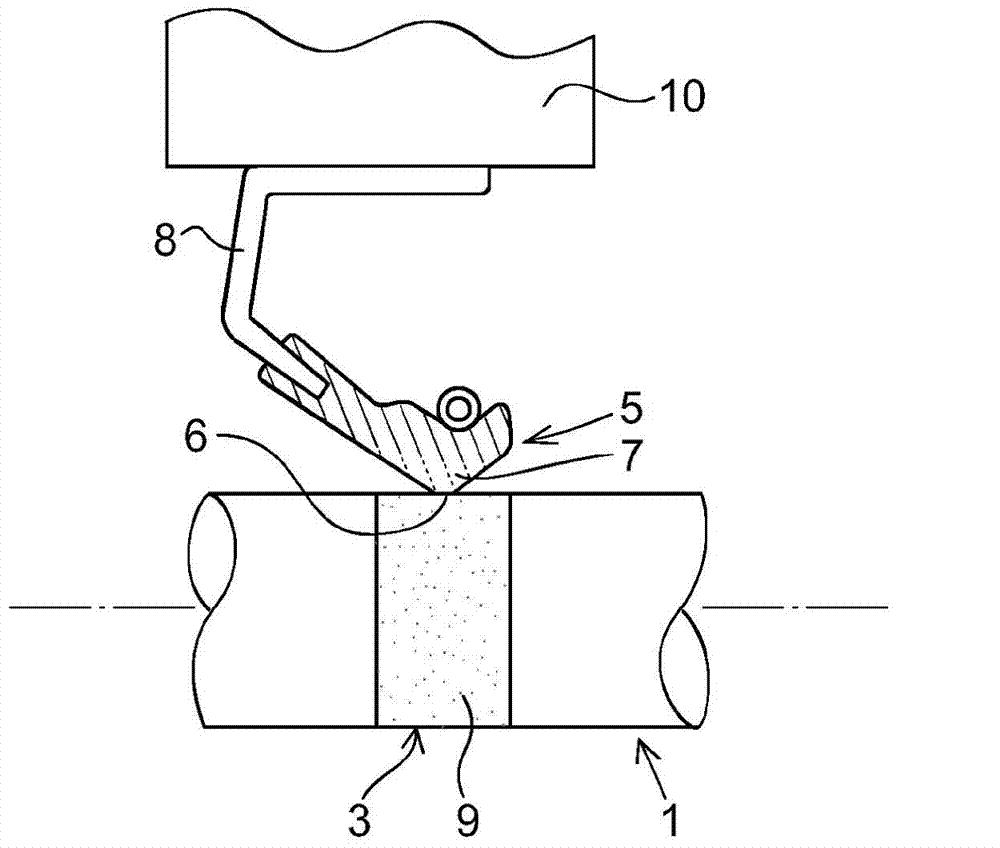

[0028] figure 1 A sealing system according to the invention is schematically shown, comprising a rotating shaft 1 provided with a sealing surface 3 and also comprising a rotating shaft lip seal 5 . This axis of rotation can be, for example, the axis of rotation of a drive unit in an industrial robot. The housing 10 surrounds the axis of rotation 1 . Between this housing and the rotating shaft 1 is arranged a rotating shaft lip seal 5 comprising a sealing lip 7 of elastic material, such as an elastomeric material, and comprising holder means 8 for mounting In the housing 10 the sealing lip is mounted on the holder device 8 . The sealing lip 7 has a sealing area 6 which is in contact with the sealing surface 3 of the rotating shaft to provide a sealing function. The function of the sealing system is to prevent the presence of figure 1 Oil or similar lubricant in a closed space such as a gearbox to the left of the lip seal 5 in the figure 1 The space on the right side of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com