A method for preparing a high-hardness, smooth, corrosion-resistant surface of ferrous metals

A black metal, high-hardness technology, applied in the field of preparation of high-hardness, smooth and corrosion-resistant surfaces, to achieve the effects of increasing surface hardness, improving high temperature resistance, and improving metal fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0029] Prepared on the surface of pure iron with a width of 2 cm and an area of 63 cm 2 Ring-shaped high-hard, smooth and corrosion-resistant surface, the design indicators are: the surface hardness is doubled (the Vickers hardness of the original surface is 135); the smoothness is ≤0.1um (the original surface roughness of pure iron is Ra 1.0 um); After being corroded in alkaline solution for 20 hours, the mass loss is reduced by more than 45%.

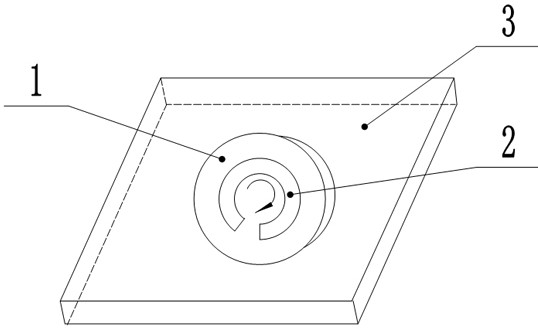

[0030] The pure iron sample to be treated is made into friction pair 1, and the grinding pair 2 is a notched annular pure iron sample. The outer radius of the notched ring-shaped grinding pair 2 sample is 6cm, and the inner radius is 4cm. The basic structure of friction pair 1 Indicate as figure 1 shown. The pure iron sample to be processed is fixed, and a load is applied to the notched annular grinding pair 2, which is driven to rotate by a motor.

[0031] The friction pair lubrication method is lubricating oil splash lubricatio...

Embodiment example 2

[0036]A 20cm×20cm ductile iron high-hardness, smooth, and corrosion-resistant surface is prepared. The design indicators are: the surface hardness is increased by more than 70% (the Rockwell hardness of the original surface of the ductile iron is 141); the surface roughness is ≤ 0.09 um (the original surface of the ductile iron is rough Degree of 0.4um,); corrosion resistance 3.5wt%NaCl neutral solution after 20 hours of corrosion, the mass loss is reduced by more than 35%.

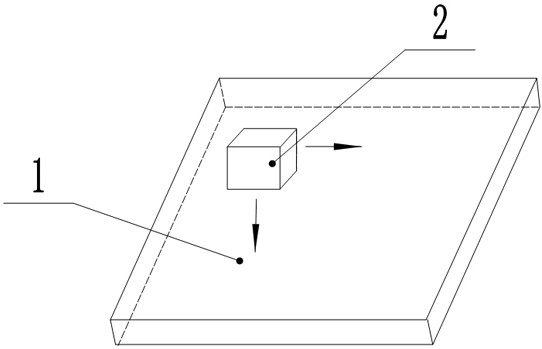

[0037] The nodular cast iron sample to be treated is made into friction pair 1, the opposite grinding pair 2 is 45# steel, the surface roughness of the opposite grinding pair 45# steel is 0.3um, and the opposite grinding pair 45# steel is a cube of 3cm×3cm×3cm . The basic structure of friction pair 1 is shown as figure 2 As shown, the ductile iron is fixed, and the load is applied to the grinding pair. The grinding pair 2 is driven by external force to perform periodic reciprocating sliding friction, ea...

Embodiment example 3

[0043] A high hardness, smooth and corrosion-resistant surface is prepared on the surface of the cylinder (excluding the bottom surface). The cylinder is 10cm high, the bottom circle radius is 4cm, the material is low carbon steel, the original surface roughness of the cylinder is 1.1um, and the design index is: surface The hardness is increased by 55% (the Rockwell hardness of the original surface of low carbon steel is 71); the surface roughness is ≤0.6um; the mass loss is reduced by more than 40% after being corroded in 3.5wt% NaCl neutral solution for 20 hours.

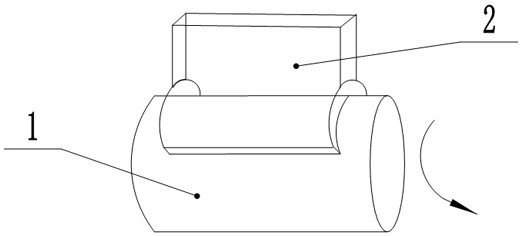

[0044] The cylinder to be treated is made into friction pair 1, and the opposite grinding pair 2 is a low-carbon steel arc, the surface roughness of the arc is 0.74um, the arc of the arc is 120º, the radius is 4cm, and the width is 10cm. The basic structure is shown as image 3 shown. The arc is held stationary and the load is applied to the arc. The cylinder rotates under the drive of the motor.

[0045] The l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com