Full-through-hole metal fiber sintered body fuel cell bipolar plate and fuel cell stack

A metal fiber, fuel cell technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of easy tearing, increase the difficulty of the stack, low yield, etc., to increase the reaction area, improve volume power, and assembly difficulty. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

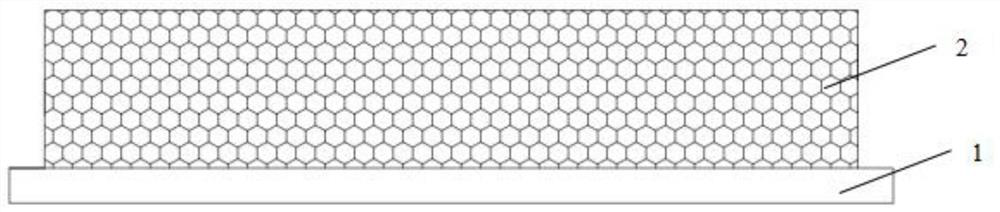

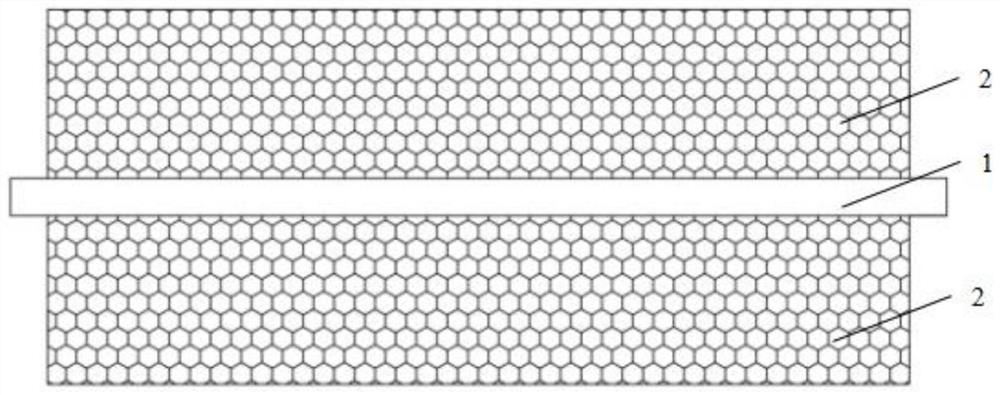

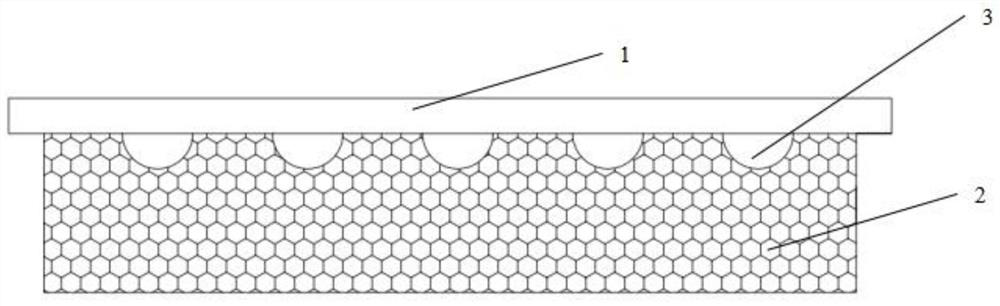

[0033]This example provides a full-hole metal fiber sintered body fuel cell bipolar plate, such asFigure 1-2 As shown, including the conductive partition plate 1 and the flow field plate 2, the flow field plate 2 is provided on one or both sides of the conductive partition plate 1, and the flow field plate 2 is provided when the conductive partition plate 1 is constituted. Unipolar board, two monopole plates are bipolar plates (such asfigure 1 As shown in, the conductive partition plate 1 constitutes a bipolar panel when the flow field plate 2 is provided on both sides.figure 2 Designed, the flow field plate 2 is a metal fiber flake plate made of a metal fiber sintered body, and the flow field plate 2 is integrated with the conductive partition plate 1 integrated sintering or welded connection or rubber connection.

[0034]In this embodiment, the flow field plate 2 and the conductive partition plate 1 can be directly connected or indirectly connected, and the direct connection includes...

Embodiment 2

[0041]This embodiment provides a fuel cell stack including a series body of a single battery, a battery stack, a cooling layer between a series single cell, and a single battery, a cooling layer, a sealing gasket between the end plates. It also includes a bolt hole and a corresponding bolt reserved for assembly; wherein the single battery is composed of a total-through-hole metal fiber flask fuel cell, and a membrane electrode and a sealing ring; the cooling layer is made of metal. The fiber mat is composed, the cooling layer is 0.1 mm to 5 mm, and the metal fiber mat constituting the cooling layer is a stainless steel fiber felt or titanium fiber felt or titanium alloy fiber felt or copper alloy fiber felt; a metal fiber felt constituting a cooling layer in a fuel cell stack The arrangement is determined according to the cooling effect, and a certain number of unit cells are arranged in a single battery, and the cooling water is turbulence in a metal fiber felt three-dimensional me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com