Solvent-free epoxy rust confining coating capable of coating in wet and rust environment

A solvent-free, rust-bearing technology, applied in the field of coatings, can solve problems such as affecting the decorative effect of the coating, affecting the metal structure performance, affecting the safety, etc. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Provided is a solvent-free epoxy rust-inhibiting paint that can be painted with wet rust, which is composed of two components, A and B. The weight of component A is 1.5 to 2.5 times that of component B.

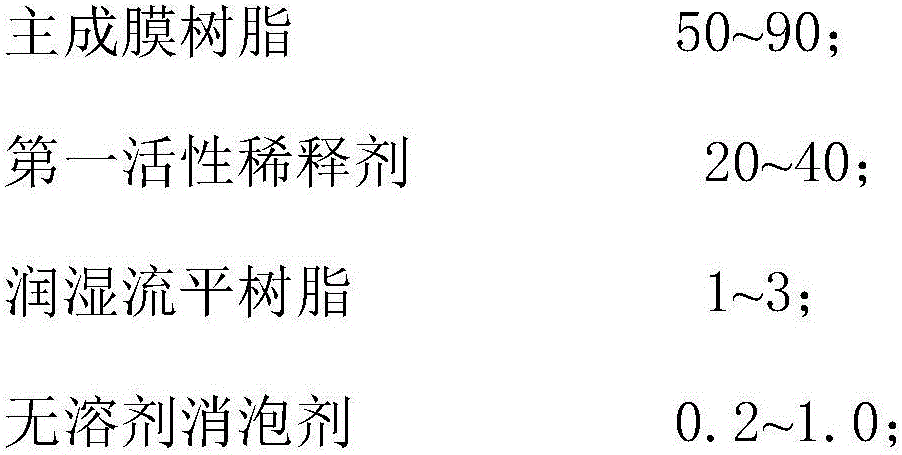

[0041] In percent by weight, the content of component A consists of:

[0042]

[0043] In percent by weight, the content of component B consists of:

[0044] Curing agent 60~90;

[0045] Modifier 2~10;

[0046] Second reactive diluent 5-15.

[0047] Among them, the main film-forming resin is bisphenol F epoxy resin, such as DER354 or EPIKOTE862, which has low viscosity, good wettability, excellent chemical resistance and corrosion resistance.

[0048] The first active agent is a hyperbranched polyether-polyester resin terminated with phenolic hydroxyl and carboxyl groups, and the second active agent is a hyperbranched polyether-polyester resin terminated with phenolic hydroxyl and carboxyl groups.

[0049] The selection of the first and second reactive diluents ...

Embodiment 2

[0057] A solvent-free epoxy rust-inhibiting paint that can be painted with wet rust. Other features are the same as in Example 1, except that the weight of component A is 2.0 times that of component B. Practice has proved that this proportion of solvent-free epoxy rust-inhibiting paint that can be painted with wet rust has better performance and lower requirements for surface treatment of objects.

Embodiment 3

[0059] A kind of solvent-free epoxy rust coating that can be applied with wet band rust, other features are identical with embodiment 1 or 2, and difference is:

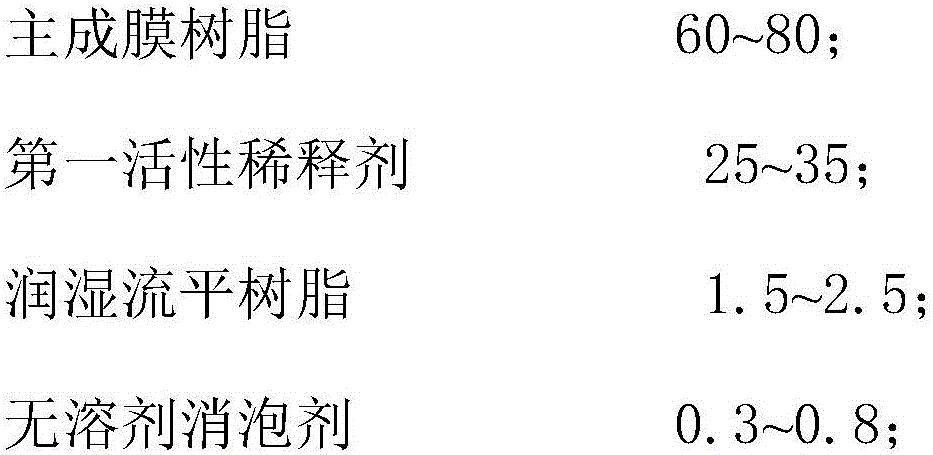

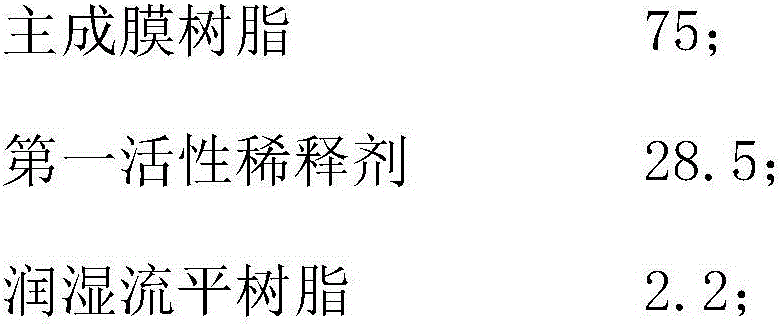

[0060] In terms of weight percentage, the content of component A consists of:

[0061]

[0062] In percent by weight, the content of component B consists of:

[0063] Curing agent 70~85;

[0064] Modifier 3~9;

[0065] The second reactive diluent 6-10.

[0066] Practice has proved that the solvent-free epoxy rust-inhibiting paint that can be painted with wet rust has excellent performance and better long-term protection performance for objects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com