Method for achieving stable dropwise condensation on heat exchange surface and efficient heat exchanger

A technology of heat exchange surface and drop-like condensation, which is applied to the device for coating liquid on the surface, special surface, coating, etc. It can solve the problems that the strength cannot meet the application requirements, increase the operating cost, and poor durability, etc., and achieve durable dripping Condensation and heat transfer phenomenon, improved performance such as heat resistance and heat conduction, and low cost of surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

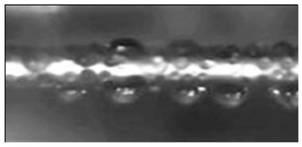

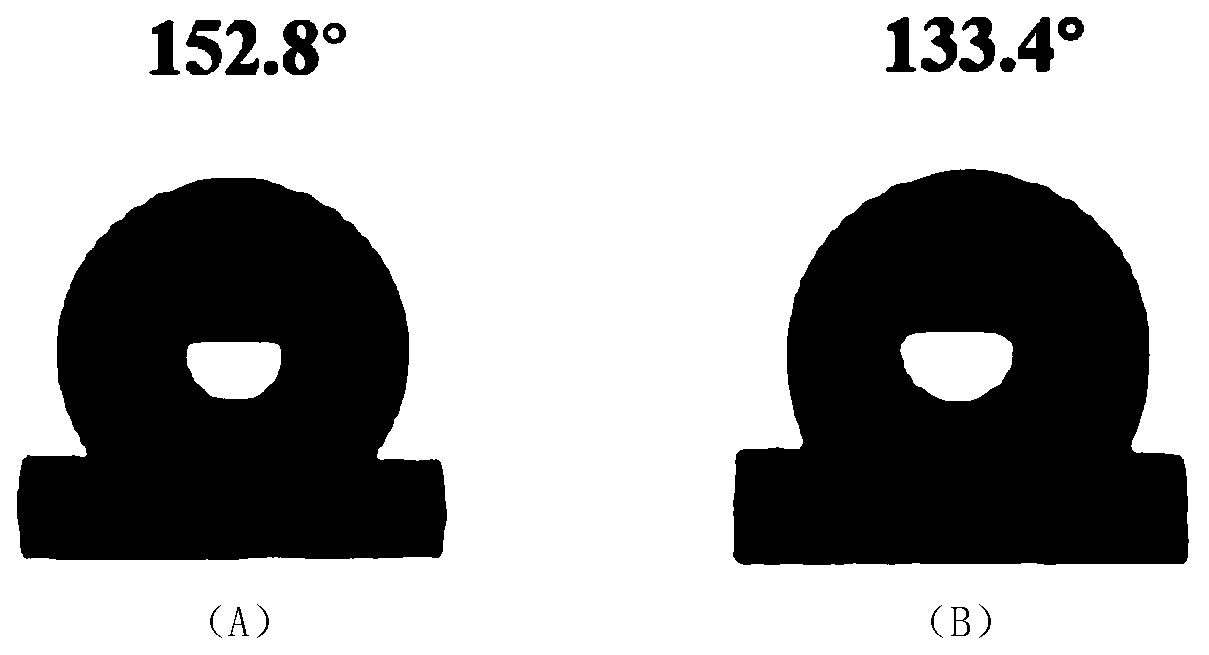

Image

Examples

Embodiment 1

[0043] The carbon steel heat exchange tube (length 650mm, inner diameter 19mm, wall thickness 2mm) is used as the metal substrate, and the metal material and the coating are determined according to the 0-level adhesion standard stipulated in GB / T9286 "Cross-cut test of paint and varnish film". The bonding strength characteristics between the layers, the coating can not reach the 0-level adhesion standard after the scratch test. Build a silicone rubber system coating on the surface of carbon steel heat exchange tubes to achieve stable and long-lasting droplet condensation. The method is as follows:

[0044] Surface pretreatment of carbon steel heat exchange tubes: wash the carbon steel heat exchange tubes in deionized water and dry them; polish the surface of the heat exchange tubes with 600 mesh, 800 mesh, and 1200 mesh sandpaper in sequence; then use deionized water and Clean the heat exchange tubes with 95% ethanol and dry them; the sulfuric acid with a mass fraction of 30% ...

Embodiment 2

[0051] Taking carbon steel heat exchange tubes (same as in Example 1) as an example, the surface pretreatment method is the same as in Example 1.

[0052] Primer treatment: prepare 15% silane coupling agent KH560 absolute ethanol solution, add di-n-octyltin dilaurate as a catalyst (the mass fraction of di-n-octyltin dilaurate is 2%), adjust an appropriate amount of glacial acetic acid to The pH is about 5, and the primer is obtained after fully stirring. Use the compressed air spraying method to spray on the surface of the pretreated carbon steel heat exchange tube, keep the distance between the spray gun and the surface of the material at 10cm, spray one layer evenly at a moving speed of 10cm / s, and dry in an open environment.

[0053] Prepare the coating material: 100 parts by weight of PDMS (PDMS with a molecular weight of about 6000 and PDMS with a molecular weight of about 18000 are compounded according to a weight ratio of 8:2), 15 parts by weight of a gas-phase method o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com